Reaching Industrial Standards: The Quest For a Dependable Internet of Things

While a few years ago only a handful of geeks and tech evangelists were teaching the gospel of connecting everything, it is safe to say that IoThas now reached the mainstream. Consequently, we are surrounded by IoT devices. Have you ever consciously counted the number of IoTdevices in your household? I did, and besides my dedicated “tech gadgets and computers” several devices, such as my toothbrush, speakers, radio, alarm clock and lightbulbs, are IoT devices, allowing me to connect to them, control them and access their information.

The usefulness of the various IoT devices we deal with in everyday life is debatable. While it is nice that I can access the weather station on my balcony remotely, I’ve not yet figured out what to do with the data my toothbrush produces (unlike my wife, who read out the data of my brush and reminds me daily that I’m brushing too hard). For companies, however, IoT helps differentiate their products in volatile markets by offering services directly related to their product and beyond.

Besides the consumer domain, IoT has strong potential for industrial applications. We are currently experiencing a 4th industrial revolution (Industry 4.0). Unlike its predecessors, this revolution is driven by market competition and the commoditization of technology is a direct result of globalization. To stay competitive, manufacturers and technology providers alike are being forced to increase adaptivity and to distribute/decentralize their manufacturing processes. Industry 4.0 is based on four design principles: interconnection (the ability to connect various entities), information transparency (the ability to utilize and aggregate information in the system), decentralized decision transparency, and technical assistance (active integration of humans in the process).

It should be clear that IoT is a major driver in this revolution. You might say “Great, problem solved, let’s move on” – but hold the horses, it’s not that easy. Although it’s clearly important, the application of IoT in industrial and safety-critical contexts such as the automotive industry provides very strict requirements. If your IoT-enabled fitness tracker decides to stop working or loses connectivity during your daily run, that’s frustrating, but the consequences are insignificant in comparison to a decentralized control algorithm or your car malfunctioning due to a loss of connectivity.

The evolution of technologies towards industrial grade IoT (IIoT) is a very active research field at the Institute of Technical Informatics in close cooperation with Pro2Future. Pro2Future is an Austrian Competence Centre for Excellent Technologies located at TU Graz and JKU Linz, which carries out co-operative industrial research projects to address the challenges and impacts of the proliferation of digitalization in the industrial domain, and its integration with novel cognitive systems. A central aspect we are currently investigating is the evolution of dependable communication technologies to satisfy the first design principle of interconnection.

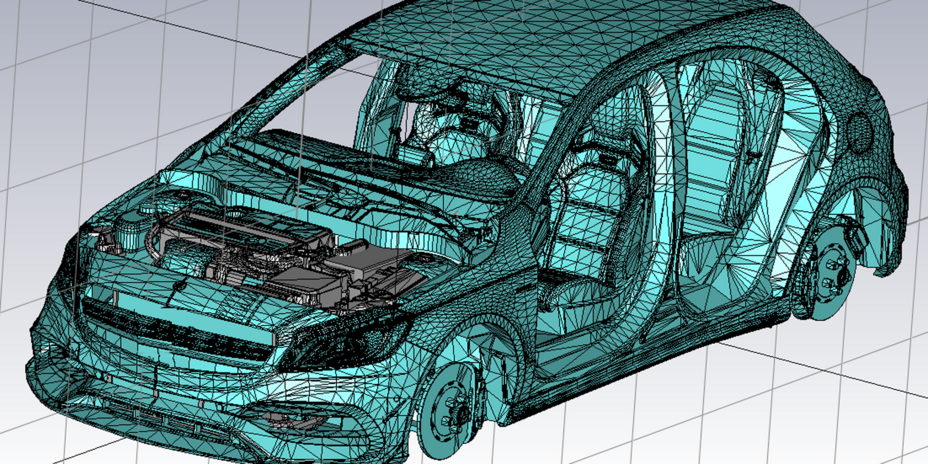

Consider a car (see Figure 1), which provides a perfect example for a miniature industrial IoT environment. In modern cars, hundreds of sensors are deployed to regulate the powertrain and provide assisted driving.

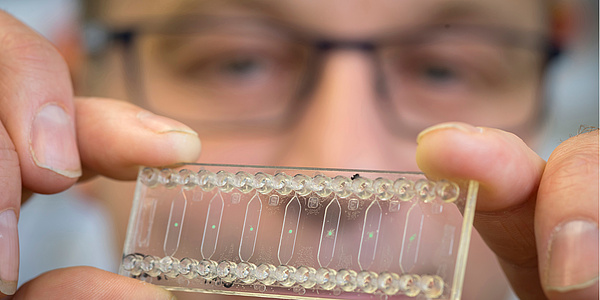

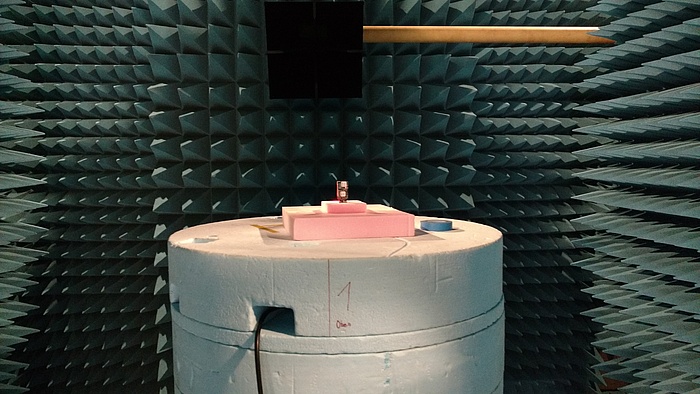

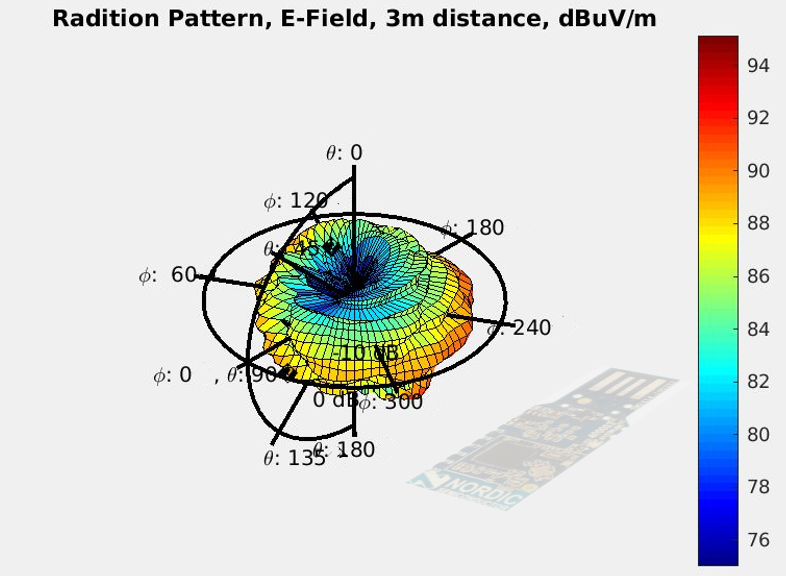

Currently, most sensors are connected by kilometers of wire, which leads to a significant increase in weight (a few hundred kilos). As in industrial environments, wireless communication technology poses a potential solution. However, the environment of the car involves metallic surfaces, temperature, vibration, and dirt, which all negatively impact the quality of the wireless communication channels (as they would on a factory floor). Another important aspect (which applies both for cars and industrial environments) is energy efficiency. For the sake of low / no engineering, sensors should be easily deployable and operate self-sufficiently over a long period of time. For cars, Bluetooth low energy (BLE, a protocol which most of us use every day to connect our phones to and with the world) poses a good fit to solve the communication problem in terms of energy efficiency and bandwidth (in factories, other technologies are used). However, using sensors with standard BLE antennas (see Figure 2) does not yield dependable communication, as their radiation patterns are omnidirectional and weak (see Figure 3).

Testing a BLEtransmitter in a measurement chamber.

Radiation pattern of a standard Nordic BLE chip (utilizing a simple meandered antenna).

In combination with metallic surfaces and obstacles in the environment, the application of such antennas will lead to no, or at best very limited, connectivity and thus undependable communication. By adapting existing designs (i.e., by changing a simple meandered antenna to a meandered inverted-F antenna (MIFA)) or using alternative antenna designs, such as slotted and patch antennas and varying design parameters, we are able to improve overall communication performance. The experimental assessment of various antenna designs in combination with the ability to model their performance in specific application environments (e.g., a specific car, a factory floor setup), allows us to evolve individual and dependable communication systems. Besides this topic there are several other research questions, e.g. in the domains of localization, services architectures or data analytics we are currently tackling to provide puzzle pieces in the big picture of industrial grade IoT solutions.

Acknowledgements: The author gratefully acknowledges the support of the Austrian Research Promotion Agency (FFG) (#6112792).