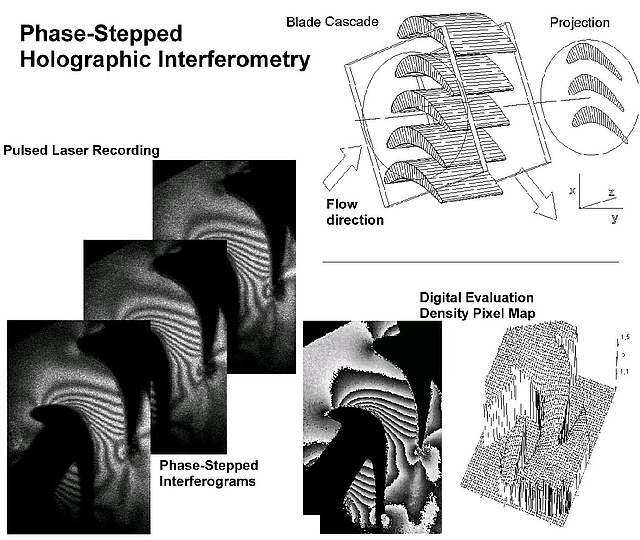

Holographic Interferometry for Flow and Vibration Analysis

Holographic Interferometry uses the fact that light fields can be stored on photosensitive media when coherent radiation (LASER light) is used. Thus, this technique enables the quantitative comparison between light waves reflected from surfaces before and after stress is applied, as well as the determination of density changes in a flow. The following picture demonstrates the principle of holographic interferometry when used for opaque objects. First a hologram of the object is recorded. To realize this, a small stress is applied; here the receiver of the phone was put on top of the phone and hot water was poured into the cup, then a second hologram is recorded. Both holograms are reconstructed simultaneously. As a result of the interference of both holograms a fringe system is visible. This fringe system can be understood as isolines of surface shift due to the load or due to thermal expansion (isoline level approximately 0.25 micrometer).

Institute of Thermal Turbomachinery and Machine Dynamics

Graz University of Technology

Inffeldgasse 25/A

A-8010 Graz

Tel: +43 (0)316 873 - 7226

Fax: +43 (0)316 873 - 107226

ttm@tugraz.at