Functional coatings

Electrochemical surface finishing comprises anodic and cathodic processes that improve appearance, functionality and/or lifetime of manufactured components. Its objectives include better wear and corrosion resistance, higher electric conductivity, and specific optical or tribological properties. Electroplating of layers of metals, alloys and composites is a highly versatile and cost effective way of creating these desired properties on the surfaces of cheap bulk materials.

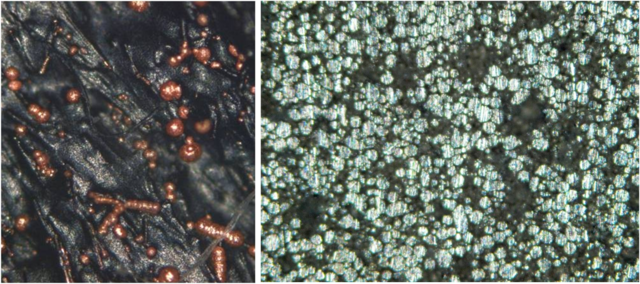

We have used electroless plating and electroplating of hard metal layers to make fibre reinforced plastic erosion resistant. We have contributed to the replacement of cadmium for corrosion protection by electroplating aluminium from ionic liquid electrolytes. We have formulated novel aqueous and non-aqueous copper electrolytes for the metallization of semiconductors. We have electroplated new zinc alloys to replace lead in the running layer of plain bearings. The electrodeposition of diamond/nickel composites has been studied, which is used on saw wire for wafer slicing. We have contributed to the development of a process for mass production of microstructured components by electroplating of metal multilayers for isothermal diffusion soldering. Clearly, electrochemical surface finishing is a key cross-sectional technology.

M. Remešová, S. Tkachenko, D. Kvarda, I. Ročňáková, B. Gollas, M. Menelaou, L. Čelko, J. Kaiser, “Effects of anodizing conditions and the addition of Al2O3/PTFE particles on the microstructure and the mechanical properties of porous anodic coatings on the AA1050 aluminium alloy”, Appl. Surf. Sci., 2020, 513, 145780. DOI: 10.1016/j.apsusc.2020.145780

P. Kosmus, O. Steiner, W. Goessler, B. Gollas, G. Fauler, " Stability of nicotinate and dodecyl sulfate in a Lewis acidic ionic liquid for aluminum electroplating and characterization of their degradation products", Electrophoresis, 2016, 37, 1095-1100. DOI: 10.1002/elps.201500452

P. Kosmus, O. Steiner, W. Goessler, B. Gollas, "Separation of 1,3-substituted imidazoles for quality control of a Lewis acidic ionic liquid for aluminum electroplating", Electrophoresis, 2014, 35, 1334-1338. DOI: 10.1002/elps.201300454

B. Gollas, A. Luegger, J. Zidar, "The electrodeposition of zinc-bismuth alloys" ECS Transactions, 2013, 50(52), 123-133. DOI: 10.1149/05052.0123ecs

P. Lammel, L. D. Rafailovic, M. Kolb, K. Pohl, A. H. Whitehead, G. Grundmeier, B. Gollas, "Analysis of rain erosion resistance of electroplated nickel–tungsten alloy coatings", Surf. Coat. Technol., 2012, 206, 2545 - 2551. DOI: 10.1016/j.surfcoat.2011.11.009

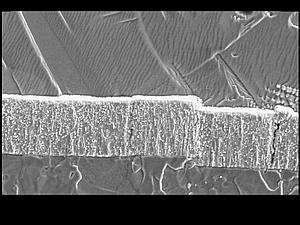

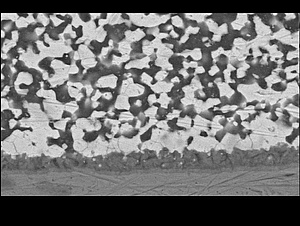

P. Lammel, A. Whitehead, H. Simunkova, O. Rohr, B. Gollas, "Droplet erosion performance of composite materials electroplated with a hard metal layer", Wear, 2011, 271, 1341-1348. DOI: 10.1016/j.wear.2010.12.034

A. Whitehead, H. Simunkova, P. Lammel, J. Wosik, N. Zhang, B. Gollas, "Rain erosion characteristics of electrodeposited Ni-SiC metal-matrix composite layers", Wear, 2011, 270, 695-702. DOI: 10.1016/j.wear.2011.02.001

M. Hacksteiner, M. Koeffler, G. Wagner, A. Trifonova, H. Antrekowitsch, B. Gollas, H. Okorn-Schmidt, “Nucleation of copper on tantalum in a liquid ammonia based electrolyte”, Proceedings of the European Metallurgical Conference, Innsbruck, 28. 6.-1. 7. 2009, GDMB, Clausthal-Zellerfeld 2009, ISBN 978-3-940276-21-6, p. 327-344.

B. Gollas, J. H. Albering, K. Schmut, V. Pointner, R. Herber, J. Etzkorn, “Thin layer in-situ XRD of electrodeposited Ag/Sn and Ag/In for low-temperature isothermal diffusion soldering”, Intermetallics, 2008 16, 962–968. DOI: 10.1016/j.intermet.2008.04.014

Institute for Chemistry and Technology of Materials

Stremayrgasse 9

A-8010 Graz

Phone: +43 (0)316 873-32338

bernhard.gollas@tugraz.at