Modelling and Simulation

The focus of our scientific work is the modelling of the microstructure evolution in technical advanced materials during processing and in service. The Christian Doppler Laboratory for Materials Modelling and Simulation is integrated in this research group.

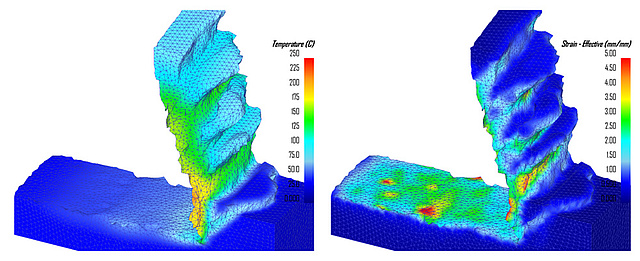

Model approaches describe the evolution of dislocation classes, of the nucleation and the growth of recrystallization and precipitate nuclei as well as of the development of subgrain, grain and particle. The process simulation is realized by the finite element method both with commercial and in-house developed programs. Additionally, the structure evolution is modelled by discrete methods like cellular automata.

Methodology and tools

- Thermodynamic, phenomenological and physical based models

- Probabilistic and deterministic cellular automata simulation

- FEM simulation

- Multi-scale modelling

- Casting

- Hot/cold deformation

- Heat treatments

- Machining

- Creep resistance

- High strength requirements

- Light-weight and energy efficiency design

Materials modelling

Thermomechanical treatments of metal alloys go along with specific microstructural features that are directly responsible for the work-hardening and softening observed in the macroscopic flow curves. One can attempt to model the microstructural changes of metallic parts during their production process by choosing an adequate set of variables (dislocation content, subgrain size, grain size, fraction of recrystallized grains, and density of intermetallic…) and calculating their evolution step by step. The establishment of evolutionary laws for the microstructure descriptors relies on a good understanding of the microscopic mechanisms involved and an effective physical representation of those mechanisms. The necessary stress to further deform the material derives from the microstructural calculations. By feeding the calculated flow stress at each thermomechanical step to a finite element code, one can simulate a whole production process with no dependence on an empirical constitutive equation.

Keywords: work-hardening, softening, microstructure evolution, calculated flow curves

Microstructure simulation

The Institute of Materials Science and Welding is actively working on modeling the micro-structure of metals and alloys, as well as the implementation of its findings in a modern pro-duction. Therefore, one of the tools of mathematical modeling is "cellular automata".

A cellular automaton (CA) is a discrete model used in mathematics, physics, complexity sci-ence, theoretical biology and microstructure modeling. The concept was originally discovered in the 1940s by Stanislaw Ulam and John von Neumann. One way to simulate a two-dimensional cellular automaton is with an infinite sheet of graph paper along with a set of rules for the cells to follow. Each square is called a “cell” and each cell has two possible states, “black” and “white”. The neighborhood of a cell are the nearby, usually adjacent, cells. The two most common types of neighborhoods are the von Neumann neighborhood and the Moore neighborhood. We have years of experience in the modeling of grain growth in the modern processes of thermo-mechanical processing. Successful results have been achieved in the description of normal and abnormal grain growth in single-phase and multiphase materials. Currently, the work is used to metallophysical description of such processes as phase transformations and static recrystallization. Attention is paid to the evaluation of the interaction of individual models in order to create a single powerful package.

A cellular automaton (CA) is a discrete model used in mathematics, physics, complexity sci-ence, theoretical biology and microstructure modeling. The concept was originally discovered in the 1940s by Stanislaw Ulam and John von Neumann. One way to simulate a two-dimensional cellular automaton is with an infinite sheet of graph paper along with a set of rules for the cells to follow. Each square is called a “cell” and each cell has two possible states, “black” and “white”. The neighborhood of a cell are the nearby, usually adjacent, cells. The two most common types of neighborhoods are the von Neumann neighborhood and the Moore neighborhood. We have years of experience in the modeling of grain growth in the modern processes of thermo-mechanical processing. Successful results have been achieved in the description of normal and abnormal grain growth in single-phase and multiphase materials. Currently, the work is used to metallophysical description of such processes as phase transformations and static recrystallization. Attention is paid to the evaluation of the interaction of individual models in order to create a single powerful package.

Thermo-mechanical processing

Metallic parts are generally submitted to thermomechanical treatments mainly to achieve certain desired shapes and properties. The deformation parameters such as temperature, strain rate and the number of steps have a direct influence on the microstructure and on the precipitation state with direct impact on the mechanical properties of the final product. Optimization of the whole process is done by finding a compromise between cheap and easy thermomechanical treatments stages to achieve both the required shape and desired mechanical properties for the product without damage.

The main objectives of the thermomechanical group are:

The group works with:

- to optimize thermomechanical processing such as forging, rolling, continuous casting and heat treatments from the energetic point of view

- to find the optimal temperature, strain, strain rate, holding time and heating/cooling rates combination to achieve desired mechanical properties (microstructure engineering)

- to model physically and phenomenologically the microstructural changes and flow response as a function of the processing parameters

- to study and avoid damage during thermomechanical processing

- to describe the dynamic and static mechanisms which lead to softening (recrystallization, recovery, coarsening, etc.) as well as the ones which result in hardening (precipitation, cold deformation, among others)

The group works with:

- Materials: low alloyed steels and titanium, aluminium and magnesium alloys

- Characterization methods (more information click here):

- Microstructure characterization: metallography using LOM, SEM, EBSD, TEM (the last two in cooperation with FELMI and USTEM) ; 3D characterization and phase characterization by means of synchrotron radiation (ESRF, DESY)

- Thermomechanical simulators: Beta, Gleeble ®3800, Bähr dilatometer

- Mechanical testing: Zwick 250 universal machine, EMCO test hardness,

- Modelling and simulation tools: FEM by means of DEFORMTM, cellular automata, precipitation kinetics with MatCalc

Group Management

Maria Cecilia Poletti

Assoc.Prof. Dr.techn.

Assoc.Prof. Dr.techn.

- Tel.

- +43 316 873 - 1676

Group members

Esmaeil Shahryari

Karsh. Karsh.A. Dipl.-Ing.

Karsh. Karsh.A. Dipl.-Ing.

- Tel.

- +43 316 873 - 1652

related links