Christian Doppler Laboratory for design of high-performance alloys by thermomechanical processing

This CD-Laboratory is active since 1st of May 2017 under the leadership of Prof. Maria Cecilia Poletti. The Laboratory comprises 4 Modules focused on the optimization of thermomechanical processes for high-performance materials.

We work together with processing industries

to answer technological questions with a scientific approach.

Our industry partners are:

Motivation and objectives

Our research is motivated by the complex microstructural evolution occurring during industrial thermomechanical processes. We aim to explain and model the microstructure evolution of non-ferrous materials during thermomechanical processing routes. These models will allow to design and process materials with high performance during service.

Our goals

- Unify the hot working, dislocation creep and relaxation phenomena in one mean-field model.

- Describe the microstructure along the production chain.

- Use and design experiments to simulate industrial processes or isolate physical phenomena.

- Propose alternative processing routes for the design of the microstructure.

MODULE 1: Nickel-based superalloys

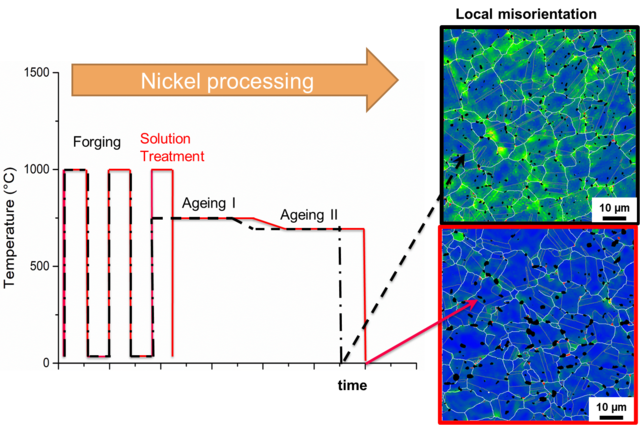

Nickel-based superalloys are high-performance materials characterized by their creep resistance and good mechanical properties at high temperatures. Despite the large amount of works in the literature, the creep mechanisms and the microstructure evolution were never correlated in depth. Therefore, here we aim at finding a correlation between the precipitation state and the dislocation density obtained from the industrial process with the creep performance of the IN718. We characterized the creep resistance and microstructure evolution of IN718 after different heat treatment routes. We developed a model to correlate the creep strain with the microstructure. It was demonstrated that the main influencing microstructural aspects on the material´s creep resistance were the initial dislocation density and the initial grain size. To a lower extent, the precipitation state of the alloy also played a role.

In addition, the hot deformation behaviour of a IN718 alloy without precipitates was characterized and phenomenologically modelled to stablish correlations with a standard IN718 alloy. It was concluded that the mechanisms that produce microstructural changes during hot deformation such as dynamic recrystallization and modification of twin boundaries occur similarly for the alloy with and without precipitates.

This module has been closed at the end of 2020.

MODULE 2: Titanium alloys

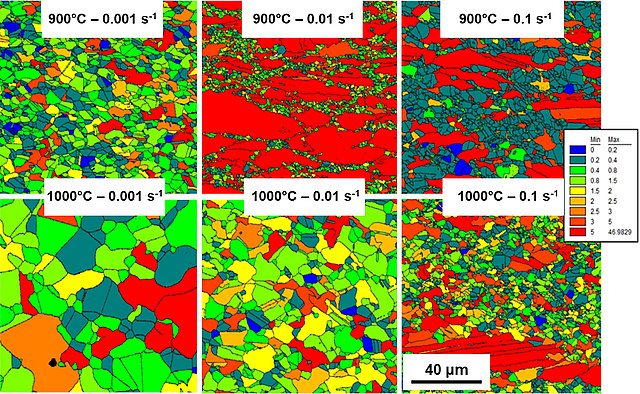

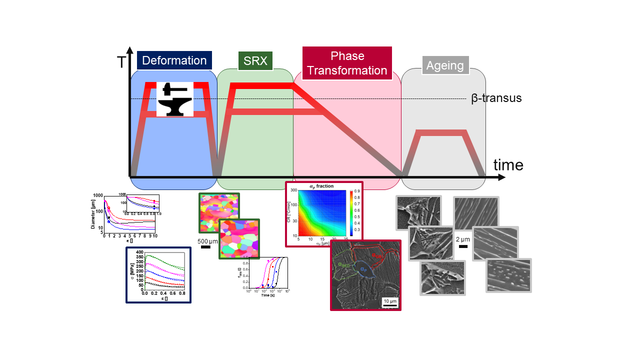

The thermomechanical processing of titanium alloys consists of many steps of hot deformation, annealing and cooling applied to modify the properties and microstructures of the alloys. In the literature there are physical and phenomenological models to describe the correlation of processing parameters with stresses, and in the best cases, with the microstructure. However, it is challenging to reproduce or predict the microstructure that develops along the whole processing chain at the different parts of an industrial workpiece. Therefore, we characterize and model the microstructure evolution as a function of processing parameters such as temperature, strain, strain rate and time. The models consider the role of SRV, DRV, CDRX, dynamic globularisation of the α-phase and load transfer. We validate the models experimentally for Ti5553, Ti17 and Ti64. The models can be used to predict the microstructural evolution considering different starting microstructures and processing conditions and are implemented in FEM for accounting local microstructures.

MODULE 3: Cast Aluminium alloys

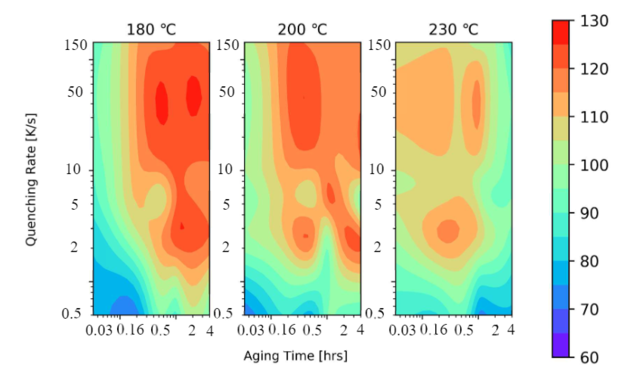

Aluminium cast alloys have been developed to keep their strength when using in combustion engines. The strength is obtained by solution heat treatment, water quenching and subsequently artificial ageing. During artificial ageing, the internal stresses produced during quenching are partially relaxed. However, the correlation of the relaxed stresses, the ageing temperatures and the precipitation modification was never done before. Therefore, we firstly characterized and modelled the relaxation and ageing behaviours of a cast AlSi7Cu0.5Mg alloy to explain the microstructural changes during all the heat treatments. Moreover, some parameters affecting the precipitation kinetics were identified. We proved that the stress relaxation occurs due to the gliding and annihilation of dislocations during the ageing process, and that the internal stresses produced during the quenching processes cannot be totally relaxed during ageing.

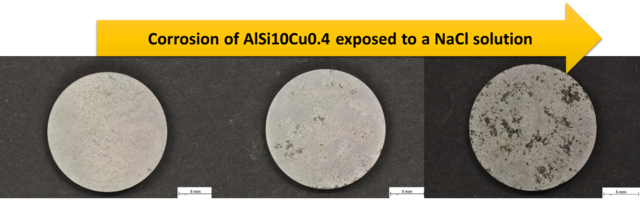

In the second part of this project, we focused on the development of aluminium cast alloys with higher Cu and Si contents. The increment on Cu should increase the strength, but decrease the corrosion resistance. For this purpose, we try to identify the mechanisms leading to the corrosion in this material, correlated to the amount and nature of primary and secondary intermetallic phases.

MIODULE 4: Wrought Aluminium alloys

The thermomechanical processing of aluminium wrought alloys consists of many steps of hot deformation and heat treatments that modify the properties and microstructures of the alloys. Furthermore, large grains can develop due to accelerated grain growth or due to abnormal grain growth due to a combination of the presence of intermetallic phases and the temperature, local deformations and velocities of deformation. However, it is challenging to control the processing parameters to obtain homogeneous grain sizes. We here investigate the influence of the initial microstructure and process parameters in the grain size evolution of AA6082 aluminium alloy exposed to direct extrusion, impact extrusion and hot forging. We aim at developing mesoscale models that account heterogeneous deformation within the workpiece, to predict the formation of undesired large grains. Furthermore, based on the understanding on the underlying metallurgic phenomena, we will propose new processing routes to reduce the grain sizes in finished components.

Additional activities

High entropy alloys have been developed in the last decades. Although promising high mechanical properties, the processing of these materials at large scale is not well established. We deformed some AlCrFeCoNi alloys using the Gleeble 3800 thermomechanical simulator with different deformation paths. The already developed unified model for hot deformation is being expanded and modified to describe the phenomena that occur during the hot compression of these alloys. We aim at producing different initial microstructures to improve strength and ductility. Par

Transient Liquid Phase Bonding was applied to Nickel based materials with the aim of producing strong intermetallic phases using low temperature melting Aluminium. This work is done in collaboration with Prof. Dr. Silvana Sommadossi at Universidad Nacional del Comahue, in Argentina.

Our journey as a team

2017 - 2020

Dr. Friedrich Krumphals moved to the industry at the end of 2019. The PhD candidates Kasyhap Pradeep (Module 1) and René Wang (Module 3) are finalizing their thesis. Ricardo Buzolin (Module 2) got his Dr. techn. title with distinction in March 2021 with his thesis entitled “Microstructure Design of Titanium Alloys via Thermomechanical Treatments”. Carolina Gonzales, student of Universidad Nacional del Comahue, completed her master work and obtained her master’s degree with distinction in July 2021.

2021 - 2024

In the new period, the group is composed by Franz Ferraz (PhD student), Esmaeil Shahryari (master student), and Emilia Guntsche (master student) for Module 2; Stefan Fortmüller (PhD Student) for Module 3 and Talina Terrazas (PhD Student) for the new Module 4. Ricardo Buzolin continues to work as deputy of the CD-Laboratory and as a post-doc covering the topics of unifying the description of and elaborating a unified model for plastic deformation related to forming, stress relaxation and creep. During this period, Marlene Eichlseder (master student) for Module 3 successfully defended her thesis entitled “Influence of Cu content on the corrosion behaviour of AlSiMgCuX alloys”.

Head

Assoc.Prof. Dr.techn.

- Tel.

- +43 316 873 - 1676

Members

Check out our publications!

Journal papers

- Z. Sajedi, R. Casati, M. C. Poletti, R. Wang, F. Iranshahi, and M. Vedani, “Comparative thermal fatigue behavior of AlSi7Mg alloy produced by L-PBF and sand casting,” Int. J. Fatigue, vol. 152, p. 106424, 2021,https://doi.org/10.1016/j.ijfatigue.2021.106424

- M. Poliserpi, R. Buzolin, R. Boeri, C. Poletti, and S. Sommadossi, “Microstructure Evolution and Phase Identification in Ni-Based Superalloy Bonded by Transient Liquid Phase Bonding,” Metall. Mater. Trans. B, pp. 1–13, Mar. 2021, https://doi.org/10.1007/s11663-021-02136-3.

- R. H. Buzolin, M. Lasnik, A. Krumphals, and M. C. Poletti, “Corrigendum to ‘Hot deformation and dynamic α-globularization of a Ti-17 alloy: Consistent physical model’ [Materials and Design 197 (2021) 109266],” Mater. Des., vol. 203, p. 109627, 2021, doi: https://doi.org/10.1016/j.matdes.2021.109627

- M. C. Poletti, “The Behaviours of Alloys under Thermo-Mechanical Treatment,” Metals (Basel)., vol. 11, no. 5, 2021, doi: https://doi.org/10.3390/met11050677

- M. Poliserpi et al., “TEM and Synchrotron X-ray Study of the Evolution of Phases Formed During Bonding of IN718/Al/IN718 Couples by TLPB,” Metall. Mater. Trans. A, vol. 52, no. 4, pp. 1382–1394, 2021, doi: https://doi.org/10.1007/s11661-021-06159-y

- F. Lizzi, K. Pradeep, A. Stanojevic, S. Sommadossi, and M. C. Poletti, “Hot Deformation Behavior of a Ni-Based Superalloy with Suppressed Precipitation,” Metals (Basel)., vol. 11, no. 4, 2021, doi: https://doi.org/10.3390/met11040605

- R. H. Buzolin, D. Canelo-Yubero, F. Warchomicka, M. Lasnik, A. Krumphals, and M. C. Poletti, “Refinement of the Ti-17 microstructure after hot deformation: Coupled mesoscale model,” Mater. Sci. Eng. A, vol. 800, 2021, doi: doi.org/10.1016/j.msea.2020.140268

- R. H. Buzolin, M. Lasnik, A. Krumphals, and M. C. Poletti, “Hot deformation and dynamic α-globularization of a Ti-17 alloy: Consistent physical model,” Mater. Des., vol. 197, p. 109266, 2021, doi: https://doi.org/10.1016/j.matdes.2020.109266

- R. H. Buzolin, M. Lasnik, A. Krumphals, and M. C. Poletti, “A dislocation-based model for the microstructure evolution and the flow stress of a Ti5553 alloy,” Int. J. Plast., vol. 136, 2021, doi: https://doi.org/10.1016/j.ijplas.2020.102862

- R. H. Buzolin et al., “Restoration Mechanisms at Moderate Temperatures for As-Cast ZK40 Magnesium Alloys Modified with Individual Ca and Gd Additions,” Crystals, vol. 10, no. 12, 2020, doi: https://doi.org/10.3390/cryst10121140

- R. H. Buzolin, F. M. B. Ferraz, M. Lasnik, A. Krumphals, and M. C. Poletti, “Improved predictability of microstructure evolution during hot deformation of titanium alloys,” Materials (Basel)., vol. 13, no. 24, pp. 1–30, 2020, doi: https://doi.org/10.3390/ma13245678

- R. H. Buzolin, D. Weiß, A. Krumphals, M. Lasnik, and M. C. Poletti, “Modelling the Competitive Growth of Primary, Allotriomorphic, and Secondary Alpha in Ti-6Al-4V,” Metall. Mater. Trans. A, 2020, doi: https://doi.org/10.1007/s11661-020-05810-4

- Z. Sajedi, R. Casati, M. C. Poletti, M. Skalon, and M. Vedani, “Thermal fatigue testing of laser powder bed fusion (L-PBF) processed AlSi7Mg alloy in presence of a quasi-static tensile load,” Mater. Sci. Eng. A, vol. 789, p. 139617, 2020, doi: doi.org/10.1016/j.msea.2020.139617

- M. Poliserpi, R. Buzolin, R. Boeri, C. Poletti, and S. Sommadossi, “Analysis of Splitting and Martensitic Transformation of AlNi Intermetallic Obtained by Transient Liquid Phase Bonding,” Metall. Mater. Trans. B, vol. 51, no. 3, pp. 916–924, 2020, doi: https://doi.org/10.1007/s11663-020-01832-w

Conference papers

- R. H. Buzolin, F. Krumphals, M. Lasnik, A. Krumphals, and M. C. Poletti, “A continuous dynamic recrystallization model to describe the hot deformation behaviour of a Ti5553 alloy,” J. Phys. Conf. Ser., vol. 1270, no. 1, p. 12048, Aug. 2019, doi: https://doi.org/10.1088/1742-6596/1270/1/012048

- M. C. Poletti et al., “Continuous dynamic recrystallization during hot torsion of an aluminum alloy.,” J. Phys. Conf. Ser., vol. 1270, p. 012049, Aug. 2019, doi: https://doi.org/10.1088/1742-6596/1270/1/012049

- R.H. Buzolin, D. Weiss, A. Krumphals, M. Lasnik, and M. C. Poletti, “Phase transformation sequence of Ti-6Al-4V as a function of the cooling rate,” MATEC Web Conf., vol. 321, p. 12038, 2020, doi: https://doi.org/10.1051/matecconf/202032112038

- R. Wang, F. Krumphals, M.C. Poletti. Relaxation von Eigenspannungen in einer Al-Gusslegierung während des Warmauslagerns, Conference: 10 Ranshofener Leichtmetalltage, 13.06.2018 – 14.06.2018.

- Poletti María Cecilia, Buzolin Ricardo, Kumar Sanjeev, Wang Peng, and Simonet-Fotso Thierry Franz Jules. Microstructure evolution of Ti-5Al-5V-5Mo-3Cr after hot deformation at large and moderate strains. Accepted for Journal of Materials Science Forum (Conference TERMEC 2018)

Oral presentations

- S. Fortmüller (sp), M.C. Poletti, R. H. Buzolin, B. Stauder, R.F. Gutiérrez, Influence of Cu on the phases of secondary Al10SiMg alloys after heat treatments: LightMAT 2021: 4th International Conference on Light Materials, 2.11.2021 – 4.11.2021

- R.H. Buzolin (sp), F.M.B. Ferraz, A. Krumphals, D. Weiss, E. Guntsche, S. Sommadossi, M.C. Poletti, Integrated modelling tools to simulate the evolution of the microstructure in titanium alloys along the production chain: 2021 European Congress and Exhibition on Advanced Materials and Processes : EUROMAT 2021, 13.9.2021 – 17.9 2021

- F.M.B. Ferraz, R.H. Buzolin, M.C. Poletti, A. Krumphals, Prediction of microstructure gradient distribution of Ti alloys during thermomechanical treatment: 2021 European Congress and Exhibition on Advanced Materials and Processes : EUROMAT 2021, 13.9.2021 – 17.9 2021

- R.H. Buzolin (sp), E. Guntsche, S. Sommadossi, A. Krumphals, Lamella size and grain boundary alpha evolution during continuous cooling for a Ti17 alloy, International Conference on Processing and Manufacturing of Advanced Materials: Thermec 2021, 10.5.2021 – 14.5.2021

- M.C. Poletti (sp), F.G. Warchomicka, R.H. Buzolin, D.C. Yubero, F.M.B. Ferraz, Titanium alloys under thermomechanical treatments: common characteristics and general models: International Conference on Processing and Manufacturing of Advanced Materials: Thermec 2021, 10.5.2021 – 14.5.2021

- M. C. Poletti (sp), R.H. Buzolin, F.M.B. Ferraz, F.G. Warchomicka, P. Wang, K. Hogrefe, The behaviour of titanium alloys under thermomechanical treatments: 18th International Conference on Metal Forming: Metal Forming 2020, 13.9.2020 – 16.9.2020

- M.C. Poletti (sp), CD-Labor für Design von Hochleistungslegierungen mittels thermo-mechanischer Prozesstechnik: 8. Christian Doppler Forum 2020, 10.9.2020 – 11.9.2020

- R. Wang (sp), D. Ram, B. Stauder, R.F. Gutiérrez, Relaxation of internal stresses in an Al-cast alloy during artificial aging: LightMAT 2019: 3rd International Conference on Light Materials – Science and Technology, 5.11.2019 – 7.11.2019

- F. Lizzi (sp), K. Pradeep, G. Shcaden, A. Stanojevic, S. Sommadossi, M.C. Poletti, Hot deformation studies on a precipitate free Ni-based superalloy: CONAMET-SAM 2019, 3.11.2019 – 7.11.2019

- M. Poliserpi (sp), P. Barriobero-Vila, G. Requena, M.C. Poletti, R. Boeri, S. Sommadossi, Phase evolution in Inconel718 / Al / Inconel718 couples obtained by TLPB: CONAMET-SAM 2019, 3.11.2019 – 7.11.2019

- R.H. Buzolin (sp), F. Krumphals, A. Krumphals, M. Lasnik, P. Wang, S. Kumar, M.C. Poletti, A continuous dynamic recrystallization model to describe the hot deformation of a Ti5553 alloy: 7th International Conference on Recrystallization and Grain Growth, ReX and GG 2019, 4.8.2019 – 9.8.2019

- F. Krumphals (sp), R.H. Buzolin, T.S. Fotso, M.C. Poletti, Hot deformation of AA6082: Is CDRX or GDRX the predominant recrystallization mechanism?: 7th International Conference on Recrystallization and Grain Growth, ReX and GG 2019, 4.8.2019 – 9.8.2019

- R.H. Buzolin (sp), D. Weiss, A. Krumphals, M. Lasnik, M.C. Poletti, Phase transformation sequence of Ti6Al4V as a function of the cooling rate: The 14th World Conference on Titanium, 10.6.2019 – 14.6.2019

- R.H. Buzolin (sp), M. Lasnik, A. Krumphals, F. Krumphals, M.C. Poletti, A physical based model for the hot deformation behaviour of a Ti17 alloy: The 14th World Conference on Titanium, 10.6.2019 – 14.6.2019

- K. Hogrefe, M.C. Poletti (sp), R.H. Buzolin, Flow modelling of Ti6Al4V under large strains: The 14th World Conference on Titanium, 10.6.2019 – 14.6.2019

- R. Wang (sp), F. Krumphals, M.C. Poletti. Relaxation von Eigenspannungen in einer Al-Gusslegierung während des Warmauslagerns Conference: 10 Ranshofener Leichtmetalltage, 13.06.2018 – 14.06.2018.

- R. Wang (sp), F. Krumphals, M.C. Poletti. Relaxation of internal stresses in an Al-cast alloy during artificial ageing. Gleeble User Group Meeting 2018, 12.09.2018 – 14.09.2018.

- Mariana Poliserpi (sp), Ricardo Buzolin, Roberto Boeri, Cecilia Poletti, Silvana Sommadossi. “Phase identification in TLPB applied to Ni-based materials”, SAM CONAMET 2018, San Carlos de Bariloche, Argentina. Oral presentation.

- Stütz, M., Buzolin, R. H., Pixner, F., Poletti, M. C., Enzinger, N., Sommitsch, C. Advanced Characterization of Rotary Friction Welded Molybdenum and TZM Alloy. International Conference of Welding and Related Technologies – present and future, 5.12.18 – 6.12.18.

- Buzolin, R. H., Krumphals, F., Krumphals, A., Michael Lasnik, Wang, P., Kumar, S., Poletti, M. C. Modelling the hot deformation behaviour of a Ti5553 alloy. Materials Science and Engineering Conference, 26.09.18 – 28.09.18.

- Poletti María Cecilia (sp), Buzolin Ricardo, Kumar Sanjeev, Wang Peng, and Simonet-Fotso Thierry Franz Jules. Microstructure evolution of Ti-5Al-5V-5Mo-3Cr after hot deformation at large and moderate strains. Conference TERMEC 2018, Paris, France. 8-13.07.2018

Posters

- F.M.B. Ferraz, M.C. Poletti, P. Wang, R.H. Buzolin, Characterization and modelling the flow localization in titanium alloys during hot forming: International Conference on Processing and Manufacturing of Advanced Materials: Thermec 2021, 10.5.2021 – 14.5.2021

- R. Wang, F. Krumphals, M.C. Poletti Relaxation of internal stresses in an Al-cast alloy during artificial ageing. Advanced Materials Day, 21.09.2018. TU Graz

- Mariana Poliserpi, Ricardo Buzolin, Roberto Boeri, Cecilia Poletti, Silvana Sommadossi (sp). “Multilayer characterization of Inconel-718 and Ni couples with Al in TLPB process”, Materials Sience and Engineering (MSE), Darmstadt, Germany. Poster with oral presentation

- Buzolin, R. H., Krumphals, F., Krumphals, A., Lasnik, M., Wang, P., Kumar, S., Poletti, M. C. Modelling the hot deformation behaviour of a Ti5553 alloy. Advanced Materials Day, 21.09.2018

- Franco. Lizzi, Kashyap Pradeep, Gerald Schaden, Aleksandar Stanojevic, Martin Stockinger, Silvana Sommadossi, Cecilia Poletti. Hot deformation processing of a precipitate free Ni-based superalloy. Advanced Materials 21.09.2018. TU Graz

PhD thesis

- Ricardo Buzolin (Module 2): Microstructure control of Titanium alloys via thermomechanical processing. Started in 2017 and finished in 2021. Graduation with honors.

- Kashyap Pradeep (Module 1): Thermomechanical processing and creep behaviour analysis of Ni-based superalloys. Started in 2017.

- René Wang (M3): Relaxation of internal stresses in Al-cast alloys during heat treatments. Started in 2017.

- Franz Ferraz Miller (Module 2): Thermomechanical treatment of Ti alloys, with focus on Ti-64. Started in 2020.

- Stefan Fortmüller (Module 3): Corrosion resistance and ageing of AlSi10MgCuX alloys. Started in 2021.

- Talina Terrazas Monje (Module 4): Thermomechanical treatments of AA6082 aluminum alloy. Started in 2022.

Master thesis

- Franco Lizzi, Universidad Nacional del Comahue – TU Graz (Module 1): Hot deformation behaviour of precipitates free Inconel®718. Started in April 2018. Exam in Argentina in July 2019.

- Desirée Weiß (Module 2): Phase transformation of Ti-6Al-4V during cooling. Started in April 2018. Exam in January 2019.

- Carolina Gonzalez (Module 2): Modelización de la cinética de precipitación y caracterización de una aleación Al-Si-Cu-Mg para fundición. Exam in July 2021.

- Dinesh Ram (Module 3): Determination of the effect of the cooling rate in the age hardening of Al7Si0.5CuMg. Started in May 2018. Exam in February 2019.

- Marlene Eichlseder (Module 3): Influence of Cu content on the corrosion behaviour of AlSiMgCuX alloys. Exam in August 2022.