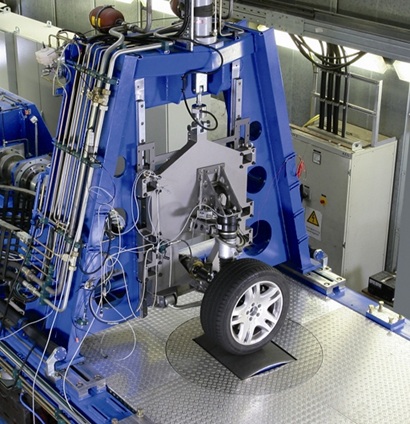

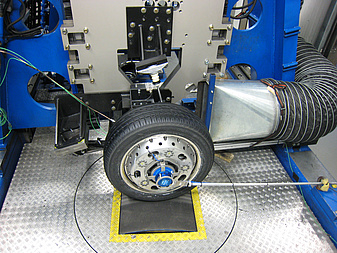

Wheel suspension and brake test bench

The combined suspension and brake tester differs significantly in structure from conventional axle and chassis test stands.

On the wheel suspension test stand, the wheel on which the tire rides can realistically simulate the adhesion between the wheel and the road surface. This results in the following advantages:

- Real introduction of forces and moments in the landing gear

- Possibility of introducing damage-relevant brake heat into the test parts

- NVH-investigations under controlled conditions