OPED: AI-Powered Engineering Software

for Electric Drives

Boosting powertrain development with agility, fast time-to-market and optimal product-market fit

Designing electric powertrains is challenging: engineers must quickly find competitive designs and optimize the system for multiple key performance indicators (KPIs) at once, e.g., efficiency, cost, and package. The industry-approved engineering software OPED (Optimization of Electric Drives) can do this automatically by combining parametric system models with an AI-based optimization algorithm and exploring hundreds of thousands of design variants within 24 hours.

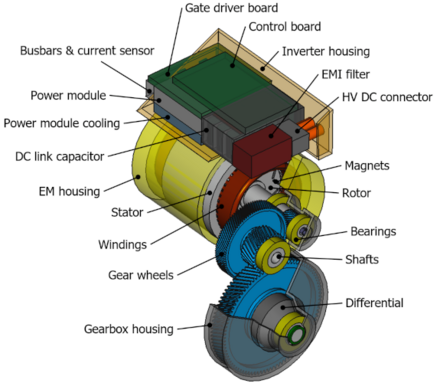

Development of Electric Drives

The development of electric drives (e-drives) is a highly complex and interdisciplinary process. Engineers must simultaneously design numerous electrical and mechanical subsystems that must optimally work together while meeting ambitious system targets for performance, efficiency, cost, and packaging. These objectives are often conflicting – improving one typically worsens another. Moreover, this highly challenging task must be solved under strong time pressure as it is critical for ambitious time-to-market goals. Therefore, engineering of electric drives demands digital tools capable of handling multi-criteria optimization and cross-domain interactions in an integrated way to quickly provide solid answers to complex questions.

Revolutionizing the Development Process with OPED

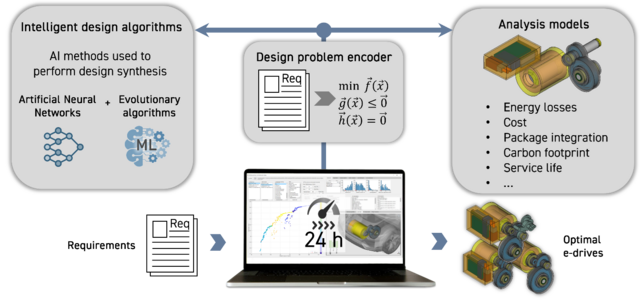

The software OPED fundamentally changes how e-drives are developed. Instead of relying on sequential design steps and manual iterations, OPED uses parametric system models combined with an AI-powered evolutionary optimization algorithm to explore the full design space automatically. The outline of OPED is shown in the figure below: Based on specified e-drive system requirements, the design problem is encoded as a multi-objective optimization problem. The intelligent design algorithms then generate different e-drive designs, which are evaluated by system analysis models. Based on the calculated design properties, the optimization algorithm rates the generated designs and aims at improving them based on the best found designs so far. This closed loop of design analysis and synthesis continues until no more improvements are observable and converging behavior is present. Furthermore, self-learning artificial neural networks boost the optimization performance by guiding the optimization algorithm and directing its search towards promising design regions. Within 24 hours of computation time, around 50 design parameters are varied, hundreds of thousands of possible e-drive designs are evaluated, and the most promising ones are identified based on multiple concurrent objectives such as

- performance,

- efficiency,

- cost,

- package integration,

- carbon footprint,

and any other design objective – everything that can be calculated, can be optimized. The result is a Pareto front of optimal solutions, providing engineers and decision makers with a clear overview of achievable trade-offs and design potentials. By merging simulation, optimization, and system understanding in one integrated workflow, OPED enables rapid development cycles. Agility is key: every request for quote (RFQ) or sudden project change request (PCR) is replied with a fast and solid answer, tailor-fit to the specific requirements. Taking informed decisions early ultimately leads to an optimal product-market fit for the e-drive system and a fast time-to-market.

Master Challenging Targets of Package, Efficiency and Cost within 24 Hours

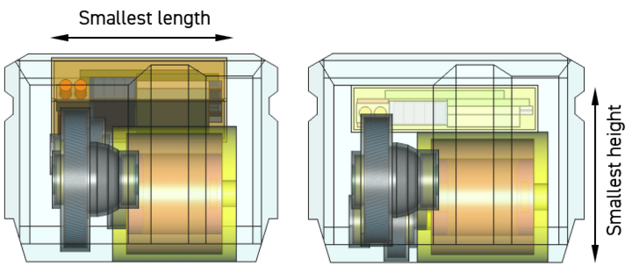

OPED’s strength lies in its versatility. The software can be applied to a wide range of design questions – from component sizing and material selection to system-level trade-offs and product family development. Moreover, as system requirements are often vague and uncertain in the early development stages, OPED can be utilized for requirements engineering. Another powerful capability lies in the full 3D package investigation: OPED not only finds designs that comply with a given 3D target installation space, it also provides possible packaging options within the available space. An example is shown in the figure below, which depicts two possible design solutions for an e-drive: One with the smallest possible length and one with the smallest possible height (e.g., providing additional trunk space for applications at the rear vehicle axle).

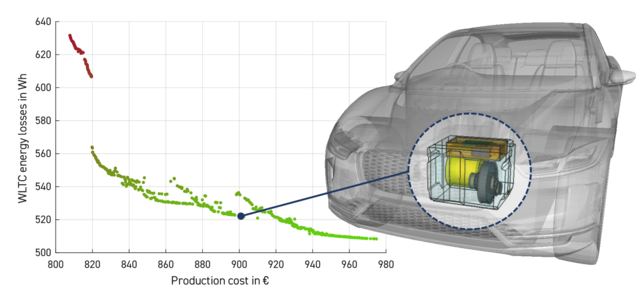

Besides package feasibility, both energy efficiency and cost are always critical and conflicting KPIs. To select the most suitable solution, OPED provides a Pareto front of e-drive designs, where each point represents one optimal design solution. Accordingly, engineers and decision makers are provided with a solid foundation for selecting the most suitable system solution respecting the specific goals of each vehicle application. As each design solution from OPED contains detailed technical information – including a 3D CAD model – a seamless and smooth transition from OPED results to the A-sample development is ensured. This makes OPED a powerful enabler for fast and digital electric powertrain development.

Concluding, OPED enables engineers and decision makers to

- respond quickly to requests for quote (RFQs) and project change requests (PCRs),

- solve conflicting KPIs & do requirements engineering,

- develop competitive solutions with product-market fit,

- design optimal product families, utilizing commonality and carry-over-parts.

OPED is established in practical use at a leading global automotive tier 1 supplier – with high potential for scaling across other suppliers and OEMs.

Get in Touch

Reach out to us for

a demo,

more information about OPED, and

licensing options.

Get in touch for a demo: