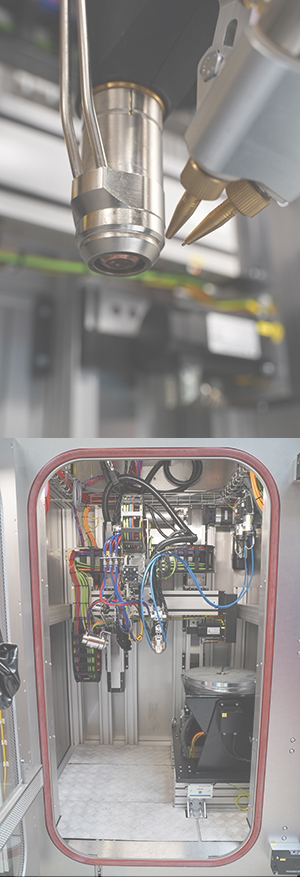

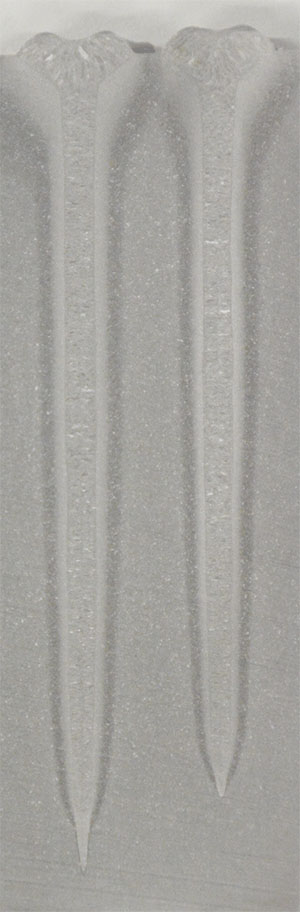

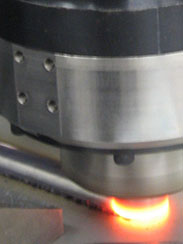

In our labs the welding processes arc welding, electron beam welding (EBW) and friction stir welding (FSW) are used. The focus is on the development of similar and dissimilar welds of alu, steel, copper, magnesium, titanium and their alloys. These processes are also used in the research areas Additive Manufacturing (AM), surface structuring as well as in changes of material properties.