FWF Project - Thermomechanical Welding (TMW)

All metallic materials consist of grains which, depending on the alloy, are only a few hundredths of a millimetre to several millimetres in size. Alloys with finer grains generally have higher strength and toughness than materials with coarser grains. Grain refinement therefore leads to a weight reduction of the components, which is associated with economic and ecological advantages.

Among the grain refining processes, thermo-mechanically controlled processes (TMCP) are the most efficient technique for most alloys. During a TMCP, metals undergo plastic deformation resulting in deformed grains with high stored energy, which supports nucleation of new grains in further high temperature treatments (recrystallisation) and refines the microstructure. At high temperatures, the microstructure tends to coarsen. To prevent coarsening of the recrystallised grains, TMCP is associated with an accelerated cooling process after recrystallisation.

During welding, grain growth also occurs due to high temperatures. Therefore, the reduction of strength and toughness of the weld metal can often not be avoided. Various techniques such as arc pulsation, electromagnetic and ultrasonic welding bath stirring have been proposed in the literature to refine the grains during welding. However, these techniques are limited to specific welding conditions and alloy compositions and can only be applied to the liquid weld metal (WM). However, in addition to WM, grain growth also occurs in the heat-affected zone (HAZ).

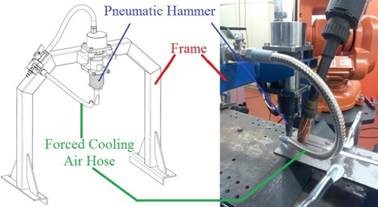

This project proposes TMW, which is comparable to TMCP, with the aim of refining grain size in both the WM and HAZ regions by means of local deformation after the welding process. To estimate the appropriate time for deformation and appropriate cooling rate, a fundamental investigation of thermodynamics, kinetics, and mechanisms of the grain growth and recrystallisation is required.

Accordingly, a comprehensive modelling is performed, which includes FEM, analytical simulation and cellular automata (CA). In parallel, physical simulations with the thermomechanical GLEEBLE system and validation experiments with the TMW process are planned. The project will investigate high-strength low alloy steels (HSLA) and austenitic stainless steels. In addition to conventional metallographic techniques, the LUMet in-situ method is also used to measure grain size and kinetics of recrystallisation in collaboration with the University of British Columbia.

The innovation of the project lies in a new combined deterministic and probabilistic CA method for the simulation of grain growth and recrystallisation and in the introduction of a method for grain refinement during welding (PhD project Mohammad Nasiri). An improvement of the welding microstructure by TMW leads to an improvement of the properties (strength, toughness) and the non-destructive testability of the weldment.

Projectleader:

Assoc. Prof. Dipl.-Ing. Dr.techn. Norbert Enzinger

norbert.enzinger@tugraz.at

phone: +43 316 873 7182

Univ.-Prof. Dipl.-Ing. Dr.techn. Christof Sommitsch

christof.sommitsch@tugraz.at

phone: +43 316 873 7180

Assoc.Prof. Dr.techn. Cecilia Poletti

cecilia.poletti@tugraz.at

phone +43 316 873 1676

Dipl.-Ing. Dr.techn. Rudolf Vallant

rudolf.vallant@tugraz.at

phone +43 316 873 1661

Peng Wang, M.Eng.

peng.wang@tugraz.at

phone: +43 316 873 1613