Testing Centre for Medical Devices: Safety for Patients

Before a pacemaker or ECG device is available on the market and used in everyday medical practice, medical devices must undergo comprehensive testing and a Conformity assessment procedure. The idea behind this is clear. Patients must be able to rely unreservedly on the benefits and, in particular, the safety of the product.

Europe's only state-accredited testing centre for medical devices at a university is located in Graz. More precisely, at the Institute of Health Care Engineering at Graz University of Technology (TU Graz). Medical products have been put through their paces there for 45 years, and for 20 years the centre was even recognized as a notified body. These so-called "Notified Bodies" decide on a European market authorisation and thus on the affixing of the CE mark.

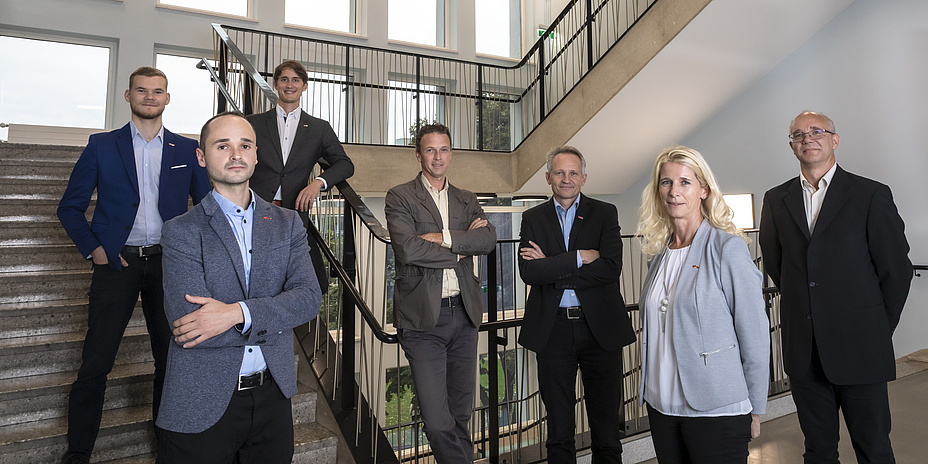

"However, in 2016 we gave up the notification for economic reasons regarding the new regulatory requirements for notified bodies laid down by the EU. We continue to work with a team of altogether seven people as a state-accredited, self-financed testing and certification centre," explains Jörg Schröttner, head of the European Testing Centre for Medical Devices at TU Graz. The Graz testing centre is allowed to test products according to a wide range of standards in accordance with its scope of accreditation and also issue certificates. "Due to the new Medical Devices Regulation (MDR), many companies that manufacture or develop medical devices are also advised by the PMG with regard to approval processes. A bonus here is, of course, the integration of the testing laboratory as a working group in the Institute for Health Care Engineering at Graz University of Technology, where research is being carried out on the medical devices of the future."

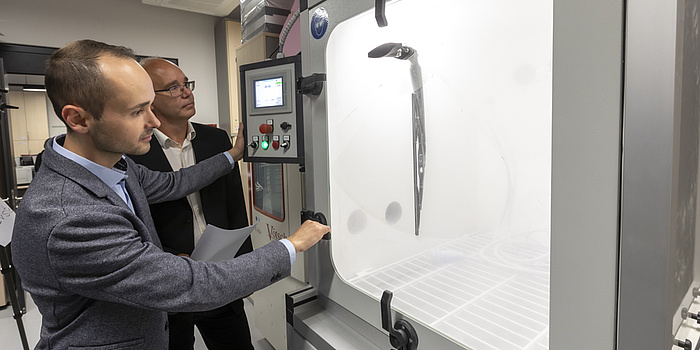

The European Testing Centre for Medical Devices carries out extensive product tests. © Lunghammer – TU Graz

In addition to type tests, which certify that a product fulfils the specified requirements of standards, basic safety tests are also on the agenda at the testing centre. Also possible are development-related individual tests like moisture protection tests in the splash water laboratory, penetration protection tests with test probes or in the dust chamber, measurements using infra-red cameras or non-invasive examinations with an X-ray apparatus. In addition to classical hardware applications, the European Testing Centre also tests and certifies medical software, including health apps. "This is a very topical issue. The decision as to whether a software is a medical device and, if so, in which conformity class it is to be classified, plays an essential role for product approval. The PMG is currently being contacted very frequently regarding such classification enquiries," Schröttner explains.

In addition, the team is authorized to audit and certify quality management systems in accordance with EN 13485. All manufacturers of medical devices are obliged by the European Medical Devices Regulation to introduce and operate a quality management system.

Jörg Schröttner heads the European Testing Centre for Medical Devices at TU Graz. © Lunghammer - TU Graz

Focus on active medical devices

"We basically have a very broad accreditation framework and can also test and certify other products, such as laboratory and hospital equipment," Schröttner explains. "However, we decided to specialize in active medical devices, as we have built up know-how in this field for many decades and can therefore provide the best possible support."

The Graz testing laboratory can accompany manufacturers of medical devices of conformity class I (with a low patient risk) up to market access, as these do not require approval by a notified body. "We can offer these manufacturers a complete package ranging from safety inspections to certification of the quality management system," explains Jörg Schröttner.

Adverse environmental influences can be simulated in the dust chamber. © Lunghammer - TU Graz

Testing the testing centre

The testing centre itself is inspected and subjected to in-depth audits by the Ministry for Digital and Economic Affairs regularly (up to three times a year). "This is how our accreditation is regularly renewed. In the past years, there has not been a single recall of or incident with a product that was tested and approved by us," adds Schröttner.

Complex body of knowledge

In addition to testing, Jörg Schröttner sees the comprehensive support of manufacturers in research and development as one of the most important tasks of the testing centre. "The approval of a medical device is a very complex procedure. There are supranational regulations, national laws, standards and recommendations from notified bodies." The relevant knowledge is available at TU Graz and can be requested for internal TU Graz developments as well as by external companies and start-ups.

This research area is anchored in the Field of Expertise “Human & Biotechnology”, one of five strategic foci of TU Graz.

You can find more research news on Planet research. Monthly updates from the world of science at Graz University of Technology are available via the research newsletter TU Graz research monthly.

Kontakt

Jörg SCHRÖTTNER

Institute of Health Care Engineering with European Testing Centre for Medical Devices

Stremayrgasse 16/II

8010 Graz

Tel.: +43 316 873 7395

schroettner@tugraz.at

www.pmg.tugraz.at