Additive Manufacturing: The 3D Revolution

This article has just been published in our research magazine TU Graz research. You can read or download the latest issue directly as an e-paper. The magazine is published twice a year - you can subscribe to it digitally or as a print version at www.tugraz.at/go/research-journal

Researchers use plastic 3D printing to produce prototypes quickly and cost effectively. In the construction industry, research is under way into concrete mixtures and print heads that could be used to print entire houses. Precision, lightweight, robust aircraft parts can be made from composites using 3D printers, and medical specialists are aiming to print entire implants directly in hospitals in future. Meanwhile, printed electrodes are a straightforward method for measuring various physiological signals.

All of these examples are taken from TU Graz research projects that involve 3D printing – and they highlight the huge potential of this revolutionary technology.

Metallic Printing

Despite in-depth research and numerous advances in recent years, additive manufacturing still faces a wide range of challenges. Critics say the procedure is too slow, too cost-intensive and not precise enough. Now, TU Graz is aiming to dispel these criticisms, as Franz Haas of the Institute of Production Engineering explains. Together with Christof Sommitsch from the Institute of Materials Science, Joining and Forming, Haas is working in the newly established AddLab@tugraz, where all of the university’s work on metallic 3D printing are consolidated and will be further expanded in the future.

For further details on the AddLab@tugraz read the Franz Haas´s interview.

But the vision goes further than this. Haas wants to tackle the production process in full – from design all the way through to post-processing: “We are currently working on a 3D printer designed and made at TU Graz that also integrates post-processing.” Christian Höller from the Institute of Production Engineering is working on his dissertation, supervised by Rudolf Pichler, on the development and evaluation of measures to increase the economic efficiency of metal 3D printing. The process starts with the preparations for printing, known as pre-processing. “We use software that optimises the topology of building components, in line with the principle of designing for additive manufacturing. Thanks to the opportunities opened up by 3D printing, we are in a position to totally rethink building components, design them to be efficient and stable at the same time, and create highly complex structures,” comments Höller. Höller and Pichler analysed the standard parameters of the institute´s printer, with a view to enhancing the printing process, and fine-tuned them so that the printing speed went up while at the same time maintaining the strength and density of the printed elements. “And the fact that this elegant approach enabled us to minimise the support structures for the printed parts was a useful knock-on effect.” However, the unloved supporting elements have not been entirely removed, and this makes post-processing arduous and expensive – every building component needs to be separated from the print bed and from the support structures, and precisely finished. In this regard, Höller also believes that he and his colleagues are moving in the right direction with the concept of “Direct Machining”: “We found a way to insert the print bed in the milling machine together with the support structures, and in this way we were able to finish the printed item straight away.”

Improved Metallic Powder

Mateusz Skalon of the Institute of Materials Science, Joining and Forming is focusing his attention on one of the basic ingredients used in additive manufacturing. He has succeeded in modifying the surface of conventional 316L stainless steel powder particles, which increases the stability of the liquefied metal in the melting pool. As a result, more complex structures at lower angles of inclination do not collapse when printed with NewGen SLM powder, as this newly developed material is called. This allows for greater design flexibility: because horizontal printing is possible and no supports are needed, this opens the door to more complex designs, such as advanced pipe or valve systems like those required in flow chemistry, as well as low-angle lattice structures and parts with optimised topologies. As Skalon explains, “This translates into savings of up to EUR 114 per kilogram of printed powder.”

Read more on Mateusz Skalon´s work on TU Graz´s website.

Composites

Cost savings are also an important consideration in Sergio Amancio’s line of research. The Austrian Federal Ministry of Transport, Innovation and Technology (BMVIT) endowed professor for aviation, who is also a member of the Institute of Materials Science, Joining and Forming, is working on lightweight, yet robust composite components for the aviation industry. “Every single gram of weight reduction delivers significant cost savings,” he tells us. “We aren’t working on a specific component; instead we’re providing momentum for new developments and performing fundamental research. Of course, our findings could also be used in automotive manufacturing or aerospace.”

Amancio’s research concentrates on components which, for reasons of stability and lightness, are composed of a combination of metal and polymers. “Combining these two materials is inherently very difficult. The polymers burn at temperatures at which the metal is only just beginning to warm up.” But 3D printing can provide a solution to this dilemma: first, the metal structure is printed and then the polymeric casing or coating is printed directly onto it. “Our aim is to support the design of future lightweight aircraft that consume less fuel and in turn produce lower CO2 emissions.”

You can read more about Sergio Amancio’s work in The best ideas are the craziest.

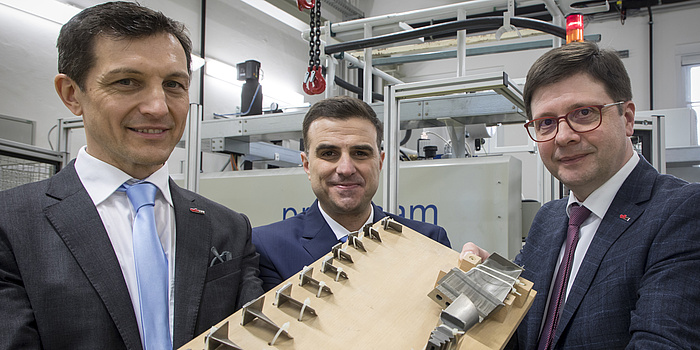

Christof Sommitsch, Sergio Amancio and Franz Haas at the laboratory.

Medical Application

In the medical sector, additive manufacturing will increasingly be used in surgical procedures, with custom prosthetics and implants produced in the operating theatre. For example, the Institute of Computer Graphics and Vision, the Institute of Engineering and Business Informatics and, more recently, the Institute of Production Engineering are currently working on the additive manufacture of implants in the COMET K project CAMed with the Medical University of Graz. The aim is to be able to replace damaged cranial bones or ribs less invasively. At present, the section to be replaced has to be measured in a first operation, then the implant is manufactured – a cost-intensive process – and inserted in a second operation. The risks associated with a second operation could be avoided with direct production in the hospital.

Read more on the CAMed project on the project´s website.

In this regard, finding solutions to safety-related questions will be paramount. At present, metallic 3D printing primarily uses the SLM procedure, which involves melting a metallic powder with a laser. “Because of the risks associated with this approach, that’s something which people obviously wouldn’t like to see in a hospital.” So Haas and his team are working on a solution: the SLEDM approach uses a high-powered LED beam to melt the metallic powder, which is far less risky than using a laser.

3D printing of plastics is currently the most highly developed option. It is widely used to produce prototypes and models – at TU Graz primarily in the Schumpeter Laboratory for Innovation run by the Institute of Innovation and Industrial Management. Headed by Hans Peter Schnöll, the laboratory is open to students, researchers and businesses alike, and enables them to implement a host of different printing projects. Visit the Schumpeter Laboratory for Innovation on TU Graz´s YouTube channel.

Tattoo Electrodes

Another new medical application has been developed by Francesco Greco of the Institute of Solid State Physics. Using a standard inkjet printer, he has succeeded in printing conducting polymer electrodes onto the kind of paper used for stick-on temporary tattoos. The electrodes can measure various physiological signals, such as providing long-term ECG monitoring as well as sensing muscle activity and even brain signals. “That’s the beauty of our development. What we’ve come up with is very hard-wearing, easy to attach and ultra-thin, and it adapts perfectly to the skin. Doing everything using affordable, existing technologies was an important factor for us,” Greco points out. He is aiming to develop sensors to collect long-term measurements that patients can simply attach themselves.

And he has big plans for the future: in collaboration with the Institute of Neural Engineering, Greco wants to continue moving in the direction of brain-computer interfaces, using the tattoo electrodes to measure brain commands or stimulate muscles that can no longer be controlled. “The particularly interesting thing about the application is that our electrodes don’t require gel, in contrast to those used at the moment, so they remain fully functional for several days,” says Greco. “And they also work when hairs grow back in the area under the adhesive paper.”

Play video

Printed Concrete for the Construction Industry

Researchers from the Institute of Structural Design, the Laboratory for Structural Engineering and the Institute of Structural Concrete are examining new possibilities for producing concretebuilding components, with a view to achieving resource-efficient, eco-friendly construction. “Several groups around the world are currently working on printing walls. On the other hand, we’ve been looking at ways in which we might be able to print complex, load-bearing components,” explains Stefan Peters, who coheads the research team with Andreas Trummer. In 2018, they developed a print head and a special concrete mix, taking concrete printing to a new level. The first printing tests ended promisingly. This research will give rise to a COMET project due to be established this winter, entitled “digital bauen – digitize building”. The project will deal with new possibilities in terms of concrete printing, and will also investigate how the construction process as a whole can be optimized using digital methods.

Play video

Revolutionary Method

There’s no doubt that 3D printing has the potential to revolutionise the manufacturing industry. And its influence extends to a range of other disciplines. But the aim is always the same: to improve current approaches, make life simpler and protect the environment.

This research area is anchored in the Field of Expertise “Mobility & Production”, one of five strategic foci of TU Graz.

You can find more research news on Planet research. You can receive monthly updates from the world of science at Graz University of Technology via the research newsletter TU Graz research monthly.