Flywheel Energy Storage System as a Fully Automatic Charging Station

Innovative charging and storage solutions have become much more important due to the growing availability of renewable energies such as solar, wind and hydro power and the increases in the field of electromobility. They are intended to store power generation surpluses for those times when renewables are not supplying electricity, in order to increase grid stability and to provide an adequate charging infrastructure. With FlyGrid, a project consortium consisting of universities, energy suppliers, companies and start-ups presents the prototype of a flywheel storage system that has been integrated into a fully automated fast charging station, thus enabling the improved use of local volatile sources.

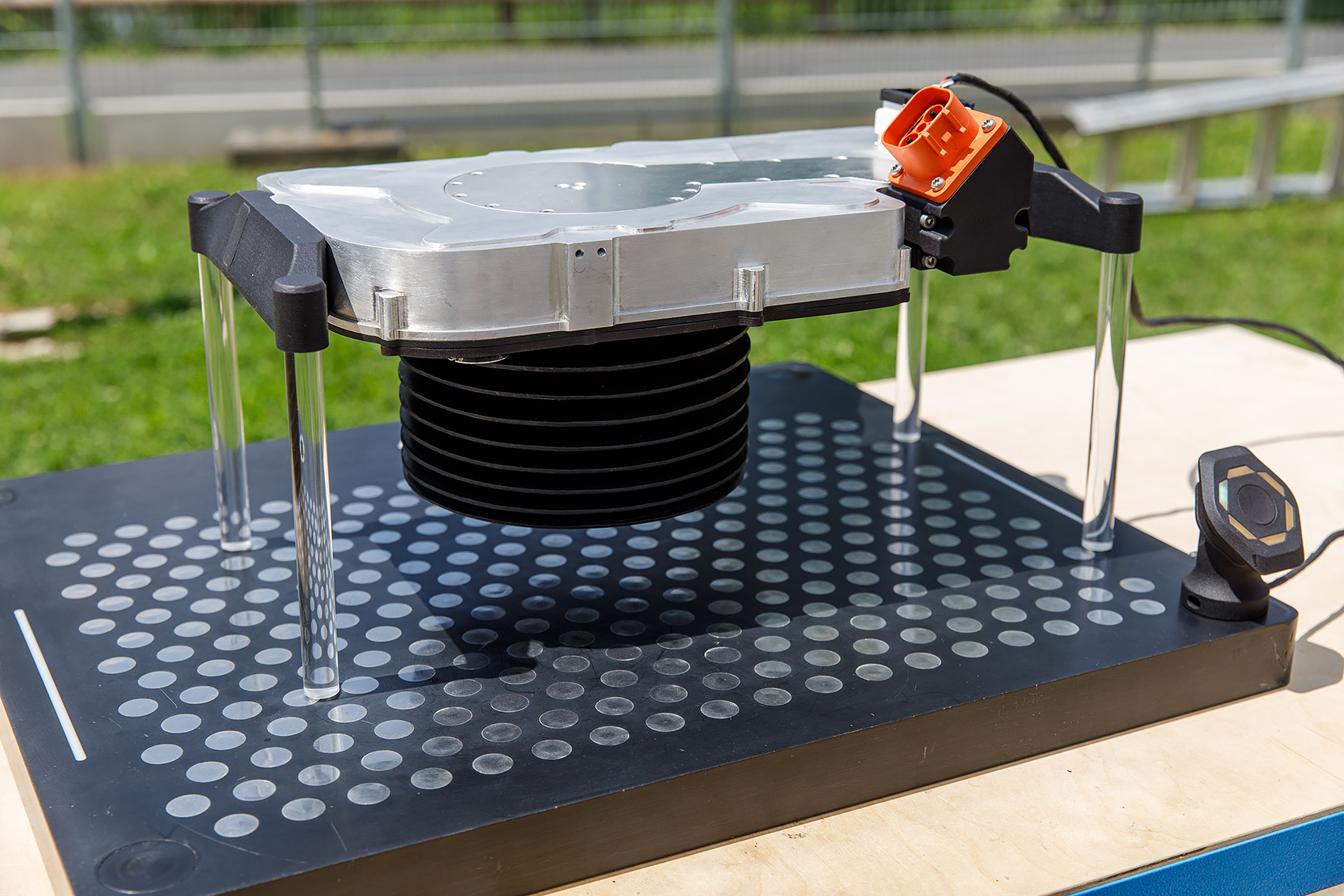

After several months of laboratory testing of FlyGrid at the University of Leoben, the flywheel storage system has now been put into operation at Energie Steiermark, where it can be further improved under real conditions. The prototype's buffer storage has an energy content of five kilowatt hours and offers a charging capacity of 100 kW. Larger storage volumes are also possible due to the modular design. Although the technology of flywheel storage is one of the oldest forms of energy storage, one of the first variants being the potter's wheel, it was necessary for the development of FlyGrid to adapt the subsystems and components to new requirements. For mechanical energy storage, a rotor – the eponymous flywheel – is accelerated to a high speed by means of an electric motor and the energy is stored as rotational energy. The energy is recovered by the rotor giving off its rotational energy to a generator. The entire development and production took place in Austria.

Service life not dependent on charging cycles

The development partners paid special attention to the rolling bearings, with rolling bearing manufacturer myonic playing a leading role. They have to withstand speeds of up to 30,000 revolutions per minute with a rotor weight of 160 kilograms. Since the amount of energy that can be stored in the rotor is limited by the centrifugal force, high-strength carbon fibre was used for its manufacture. Project partner FWT has developed a special manufacturing process for the carbon fibre composite rotor. The rotor is accelerated by a loss-optimised, synchronous reluctance motor, which was conceived by the company Thien eDrives. This electric motor technology was chosen because it achieves a very high degree of efficiency and does not require magnets or rare earths. However, the motor consumes energy to maintain the charge, which means that the storage unit discharges over time and is empty after about 25 hours. FlyGrid should therefore be seen as a short-term storage system that is only viable if energy is supplied and removed frequently. The system is packed in a specially developed safety housing. A major advantage of FlyGrid is the expected long service life, which, unlike batteries, is not dependent on the number of charging cycles or age.

In addition to energy storage and delivery, the project developed a holistic concept around storage that also takes into account aspects of energy supply, grid load and charging infrastructure. This is reflected in FlyGrid's intended areas of application. Among other things, local volatile sources such as PV systems are to be integrated, whose energy can be stored not only for charging but also for feeding high power into the grid. FlyGrid could also be used as a mobile fast-charging box, e.g. for electrified construction machinery. In the field of charging technology, project partner easelink contributed its fully automated charging system Matrix Charging.

Useful addition to existing solutions

“The increasing electrification of mobility and also of industry as well as the expansion of volatile renewable energy sources are a challenge for our electricity grids. Therefore, it is important to offer solutions that on the one hand relieve the electricity grid and on the other hand facilitate the use of e-mobility,” explains project leader Armin Buchroithner from the Institute of Electrical Measurement and Sensor Systems at Graz University of Technology (TU Graz). “In addition to solutions such as chemical batteries or pumped-storage power plants, FlyGrid's flywheel storage offers a long-lasting system that provides high performance. This makes FlyGrid a useful addition that supports the shift to renewable energy on a smaller and larger scale.”

This project is funded by the Climate and Energy Fund and is carried out as part of the “Lighthouses of Electromobility” programme. In addition to TU Graz, the following project partners are involved:

• myonic GmbH

• easelink GmbH

• Energienetze Steiermark

• Energie Steiermark

• The University of Leoben

• SECAR Technologie GmbH

• FWT COMPOSITES & ROLLS GmbH

• THIEN eDrives GmbH

• DAU GmbH & Co KG

Would you like to receive the latest stories, news, research stories, interviews or blog posts from TU Graz directly on your smartphone or in your email inbox? Subscribe to the TU Graz Telegram newsletter free of charge.

Kontakt

Armin BUCHROITHNER

Dipl.-Ing. Dr.techn.

TU Graz | Institute of Electrical Measurement and Sensor Systems

Phone: +43 316 873 30514

armin.buchroithner@tugraz.at