Mystery of Curling Paper Solved

Although mankind has been using paper for at least 2000 years, it still presents us with one or two mysteries. For example, it was previously unknown why paper printed on one side using inkjet printing starts to curl up after a few hours to days, even if it was flat after printing and drying. Alexander Maaß and Ulrich Hirn from the Institute of Bioproducts and Paper Technology at Graz University of Technology (TU Graz) have now discovered the reason. The cause lies in solvents contained in the ink, which migrate over time through the paper towards the unprinted side. This causes the cellulose fibres on the unprinted side to swell and the paper starts to curl.

Degree of paper curl measured with laser scanner

For their experiments, the researchers sprayed standard A4 printer paper on one side with a model ink consisting of water and the solvent glycerol. They then observed the curvature of the sheets of paper for a week using a laser scanner. While paper sprayed with water did not curl any further after 24 hours, the process continued for a week with paper sprayed with the water-glycerol mixture. The reason for this is that the glycerol, which unlike water only evaporates at very high temperatures, slowly but steadily migrated from the sprayed side of the paper to the other side.

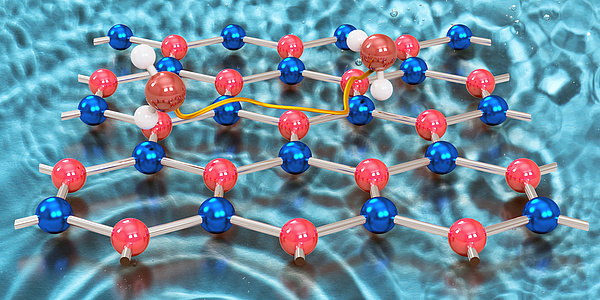

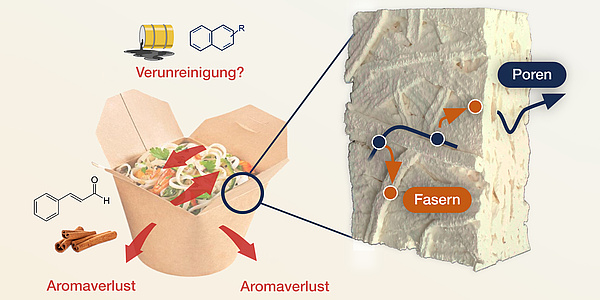

Paper separated into thin layers

The researchers were able to demonstrate this process by splitting the paper samples into thin layers and determining their respective glycerol content. They found that the glycerol continuously decreased in the upper, sprayed layers and increased in the lower ones. Since glycerol, like water, causes cellulose fibres to swell, the volume of the different paper layers changed during the test period. The layers close to the sprayed side shrank, while the deeper layers swelled up. The visible result was that the paper curled, and did so continuously for a week.

Replacing glycerol with other solvents

"To solve the problem, glycerol could be replaced by other solvents. However, this is not so easy because glycerol gives the inkjet ink important properties that make it suitable for inkjet printing in the first place," says Ulrich Hirn. Alternatively, the reverse side of the paper could also be printed or treated with an appropriate amount of glycerol.

The results, which were recently published in the journal Materials & Design, are based on work carried out at the Christian Doppler Laboratory for Fibre Swelling and Paper Performance, in which, in addition to TU Graz, the companies Kelheim Fibres, Mondi Uncoated Fine & Kraft Paper, Canon Production Printing and SIG Combibloc Systems were involved.

This research is anchored in the Field of Expertise Advanced Materials Science, one of five strategic foci of TU Graz.

Would you like to receive the latest stories, news, research stories, interviews or blog posts from TU Graz directly on your smartphone or in your email inbox? Subscribe to the TU Graz Telegram newsletter free of charge.

Kontakt

Ulrich Hirn

Univ.-Prof. Dipl.-Ing. Dr.techn.

TU Graz | Institute of Bioproducts and Paper Technology

Phone: +43 316 873 30753

ulrich.hirn@tugraz.at

Alexander Maaß

Dipl.-Ing. BSc

TU Graz | Institute of Bioproducts and Paper Technology

Phone: +43 316 873 30785

a.maass@tugraz.at