Pit stop for paper bags

But packaging and paper manufacturer Mondi reckons this is too long. They asked TU Graz to study the material flow that is at work in this process. One of the deliverables is a simulation model for material transport trough paper so that the knowledge of the “paper bags” can also be applied to other packaging applications.

Of course, the test piece on the rig is not conventional paper but so-called sack kraft paper designed to resist the filling pressure it is exposed to, for example in a cement filling line, without bursting. When a bag is filled with cement, up to 80 percent air is blown into the bag. This air can escape through pores on the paper’s surface. The Mondi-initiated Christian Doppler Laboratory (CD-Labolatory) for Mass Transport through Paper at TU Graz is now exploring these phenomena and developing simulation models to optimize the permeability of porous paper structures without compromising tear resistance.

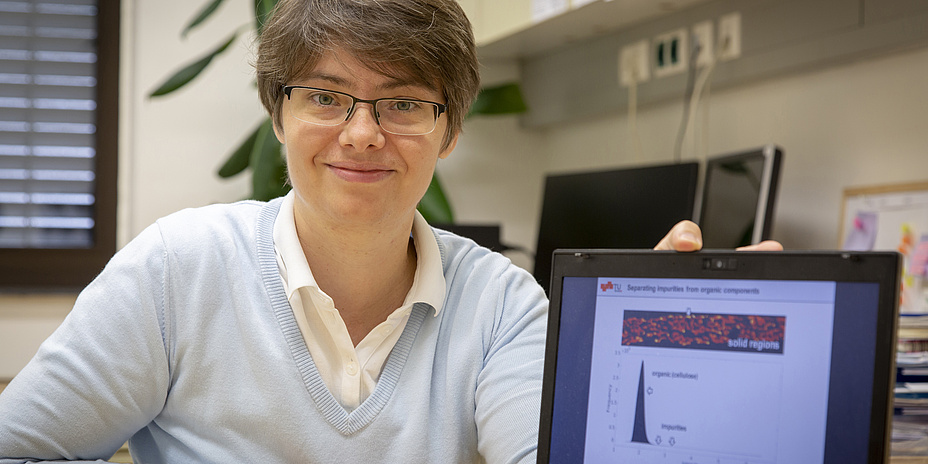

Although firmly established in the automotive industry, computer simulations of material transport through real-world materials are still in their infancy, especially if natural products such as paper are involved. “We will not be able to create a virtual clone of a paper type on the computer,” CD lab coordinator Karin Zojer admits. The physicist at the Institute of Solid State Physics is an expert for the mathematical simulation of materials and explains: “As the fibre structure of paper is enormously heterogeneous, it would take no end of data to simulate it in its full complexity. While material models already exist for plastic films to simulate the material transport on the computer, so far there are none for paper.”

With the knowledge gained in the project, concepts for the modification of paper are to be developed.

The CD-Laboratory

Researchers can now intensely research the material properties of paper packaging in the CD-Laboratory, to cast them into mathematical models. The new Christian Doppler Laboratory became operative in January 2018. Like all Christian Doppler Laboratories it builds a bridge between the worlds of business and science and in principle spans a term of seven years. The results are evaluated at two year intervals.

The CD lab for Mass Transport through Paper is an exciting proposition for researchers from many disciplines because cellulose-based fibres of the paper interact readily with the environment. To begin with, the structures change in the presence of moisture, but the fibre surfaces also exhibit chemical functionalities that may interact with substances in the system (for example the interaction with fragrances or flavourings released by food products). These substances are just what Erich Leitner’s working group at the Institute of Analytical Chemistry and Food Chemistry is looking for.

Together with company partner Mondi, the scientist and her team are investigating the material flow during the filling of cement bags in the factory.

Karin Zojer’s working group used x-ray tomography in the first stage to identify the sites where particles can potentially be deposited inside paper structures. In cooperation with Ulrich Hirn and Wolfgang Bauer from the Institute of Paper, Pulp and Fibre Technology, it is possible to plan and interpret such measurements of the microstructure specifically for paper. The experts of industrial partner Mondi support the research team of TU Graz with their in-depth knowledge in fibre technology and papermaking production procedures. They also help the researchers to formulate target-oriented mathematical assumptions for integration in future simulation models.

“The purpose of building these models is to predict how the underlying pore structure determines the transport processes,” Karin Zojer explains. “Examples of such processes include the oxygen transport in storage conditions, the drying speed of ink droplets during printing, or the air displacement processes that take place when paper bags are filled with bulk materials. In this way it is possible to pinpoint and predict the key properties of the pore structure. Consequently methods to measure these properties are also developed as part of this research project.”

As a project partner of the CD lab, Clemens Kittinger’s research team from the Institute of Hygiene, Microbiology and Environmental Medicine at the Medical University of Graz is “to contribute microbiological models and techniques to the simulation of the transport processes through the existing pore structures so that they – by looking at them from a totally different scientific angle – can ultimately be better understood and modelled,” says Karin Zojer.

The knowledge gained in the CD-Laboratory at TU Graz culminates in the development of concepts to modify paper – either to improve existing applications or to create entirely new products. And perhaps also to fill cement bags just that little bit faster. Lewis Hamilton will turn green with envy. His fastest pit stop so far was 2.33 seconds.

This project is anchored in the Field of Expertise „Advanced Materials Science“ one of TU Graz' five strategic areas of research.

Visit Planet research for more research related news.

Kontakt

Karin ZOJER

Ass.Prof. Dipl.-Phys. Dr.rer.nat.

Institute of Solid State Physics

Petersgasse 16/III

8010 Graz

Phone: +43 316 873 8974

karin.zojer@tugraz.at