Hydrogen: Electricity Storage of the Future?

Hydrogen is the first element in the periodic table. Not only here does it occupy a prominent place, but also in the discussion about an eco-friendly energy system of the future. “At the turn of the millennium, it was agreed to use hydrogen as an energy carrier,” explains Viktor Hacker, who established the Fuel Cell and Hydrogen Systems Laboratory at Graz University of Technology in 2001 and today heads the Fuel Cell and Hydrogen Systems working group. “As a strategic and climate-friendly energy carrier, hydrogen is the best common denominator for a variety of applications.”

Renewable energy sources, such as the sun, are subject to frequent fluctuations. There are many hours of sunshine in summer and few in winter for example – even rainy weather and fog have an impact on the yield of solar systems. In order to be able to compensate for these peaks and troughs, the energy must be efficiently stored and made available again. This can be done with batteries, for example. But the more energy to be stored, the larger the battery has to be. However, hydrogen could also be produced from the excess energy by electrolysis. “The advantages of hydrogen in mobility for example include the long range and short refuelling times of fuel cell vehicles, which are already comparable with conventional fuels,” explains Viktor Hacker. “Even though we haven’t quite got there yet, in the medium and long term, the costs of hydrogen as an energy carrier are the main argument in favour of it.”

Production, Storage, Transport

On hydrogen itself, there is not much left to research, Viktor Hacker continues: “Hydrogen is commercially available, it’s just currently expensive.” However, it is important to become active in the field of decentralized production, on the one hand, and in the field of hydrogen transport, on the other. Hacker’s working group took on both aspects in the HyStORM (Hydrogen Storage via Oxidase and Reduction of Metal) research project. Together with the Graz-based start-up Rouge H2, they developed the chemical-looping hydrogen method. This involves producing a syngas from biomass, biogas or natural gas, and storing its energy in a metal oxide by means of a redox process. The metal oxide can be transported and stored safely and without loss. If water is subsequently fed back into the system, high-purity hydrogen is extracted.

A system for the production of hydrogen from biomass is also being developed. In addition to the Institute of Chemical Engineering and Environmental Technology, the Institute of Thermal Engineering and the BEST (Bioenergy and Sustainable Technologies) competence centre are also involved in the BIO-LOOP project. Again together with the company Rouge H2, the developed system is to be implemented directly with a local biogas producer.

EU-Project HyMethShip

At the LEC (Large Engines Competence Center), at which the TU Graz is a major shareholder, Andreas Wimmer and his team are doing research on a propulsion concept for ships based on a hydrogen-powered IC engine. Methanol is used to store the hydrogen on board of the ship. For engine operation, the hydrogen is separated from the methanol via a membrane reactor. The CO2 produced in this process is stored and is processed back on land with green hydrogen to generate methanol again.

Key Theme: Fuel Cells

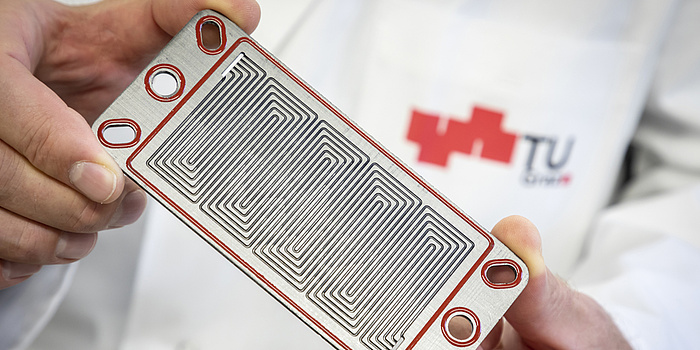

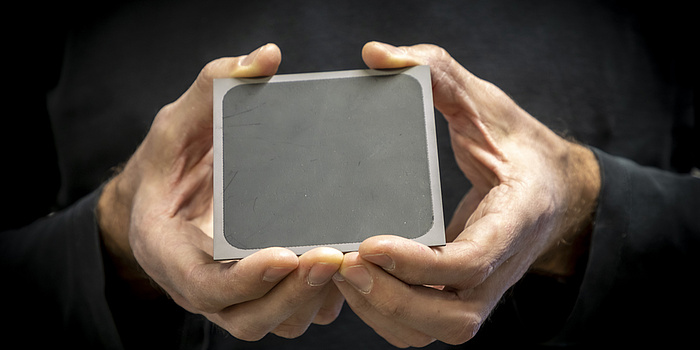

“Fuel cells will be key to the spread of hydrogen technologies because they enable us to compete with conventional technologies,” says Hacker. In the fuel cell, the energy stored in hydrogen is released again via a chemical process; it acts as an energy converter. “The main challenges at present are the service life and costs of fuel cells,” explains Hacker. He conducts research in the field of low-temperature fuel cells, especially polymer electrolyte fuel cells with an operating temperature of 80 degrees Celsius. The researchers expose the cell to adverse conditions – for example, freezing it or starting it at below 0 degrees Celsius – and try to increase its service life under these conditions. In addition, a patent has just been submitted for a method to reduce the corrosion of carbon in the electrode of the fuel cell by a thin layer of polyaniline. “We are working on the prototype of a fuel cell with this new technology.”

In the longer term, according to Hacker, the aim is also to increase efficiency. “We are currently talking about an efficiency of a good 60 percent in a fuel cell. But I think we can get a lot more out of it.”

The Fuel Cells and Hydrogen Systems research group works on low temperature fuel cells and hydrogen systems.

High-Temperature Fuel Cells

Another, still very recent type of fuel cell already has a higher efficiency. High-temperature fuel cells operate at around 800 degrees Celsius and can, on the one hand, release the energy stored in the hydrogen, but can also produce hydrogen by electrolysis in the reversible operating mode. “The electrolysis efficiencies are therefore over 80 percent,” explains Christoph Hochenauer, head of the Institute of Thermal Engineering. And low-temperature fuel cells only work with high-purity hydrogen, while high-temperature fuel cells can use a wide variety of gases, such as carbon monoxide, natural gas or ammonia. “High-temperature fuel cells are very fuel flexible and can generate electricity from almost everything that is currently available on the market,” summarizes Hochenauer. But the high-temperature fuel cell is not yet sufficiently developed to be available on the market on a large scale or to be implemented in existing applications.

Vanja Subotic´ and Christoph Hochenauer are researching high-temperature fuel cells at the Institute of Thermal Engineering.

Vanja Subotic´ ,also from the Institute of Thermal Engineering, is working on the durability of high-temperature fuel cells. “The change in operation between electrolysis and power generation means that the fuel cell ages particularly quickly,” she explains. She is investigating the processes behind this and is trying to inhibit them and ensure a long and safe operation of the fuel cell. “In the framework of the current AGRO-SOFC project, we are trying to make the agricultural industry more sustainable and reduce the costs of food production by using a highly efficient fuel cell system coupled with CO2 recycling.”

Subotic´ and Hochenauer are jointly involved in the Hotflex project. As part of an Austria-wide research association, a pilot plant for high-temperature electrolysis and fuel cell operation was built in Mellach in Styria. “Here, we are trying to define the operating limits of the plant and test its efficiency and integration in power plant operation,” explains Hochenauer. “A basic understanding of various ageing and damage mechanisms is to be created in the FWF-SOEC project. The knowledge gained in this way is to be further developed into methods that make it possible to mo¬nitor the operation of electrolysis and fuel cell plants and extend their service life,” says Subotic´.

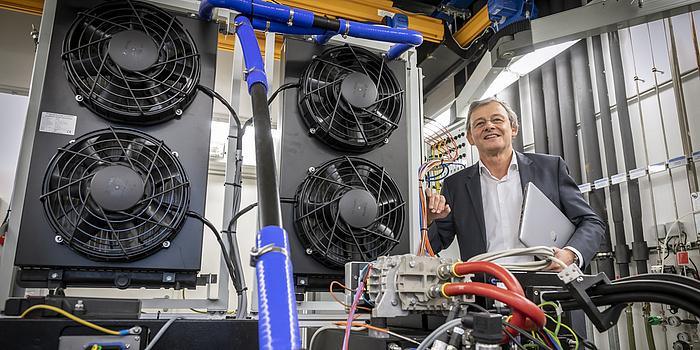

Fuel Cell and Combustion Engine

At the Institute of Internal Combustion Engines and Thermodynamics, several hydrogen-powered applications can be tested on one and the same test bench. Here, research is being conducted on both fuel cells and hydrogen-powered combustion engines. “The fuel cell has a higher efficiency than a combustion engine – at least at low loads,” explains Institute head Helmut Eichlseder. “The combustion engine, on the other hand, is robust and durable. And it could be quickly implemented technologically with hydrogen power.”

At the Institute of Internal Combustion Engines and Thermodynamics they work with fuel cells as well as with hydrogen powered combustion engines.

According to Eichlseder, hydrogen-powered combustion engines are a promising alternative, especially for heavy commercial vehicles: “The efficiency of a fuel cell decreases with the amount of the load – in heavy goods vehicles, for example, a combustion engine is the same.” In order to achieve the climate targets for 2030, the researcher is certain that at least commercial vehicles have to be converted to hydrogen propulsion. “It is feasible with relatively moderate modifications to conventional combustion engines and can be implemented on the existing infrastructure.”

Until then, there are still some things to be done on the research side. Because even hydrogen-powered combustion engines cannot be operated entirely without pollutant emissions, the exhaust gas after-treatment system must be improved in order to achieve a zero emission level. And with the Bosch company, the team is working on the injection system, which is responsible for the correct mixture formation.

Electrofuels

“Hydrogen is basically the first electrofuel; it is produced by means of electrical energy,” explains Helmut Eichlseder. He is convinced of the importance of e-fuels and sees lots of potential in them. “They are produced by electrolysis and then processed into a liquid fuel.” The e-fuels can then be used in combustion engines.

Competence Centre HyCentA

The competence centre HyCentA (Hydrogen Center Austria) at Campus Inffeldgasse, in which TU Graz has a majority shareholding, is completely dedicated to hydrogen research. The centre was established in 2005 as the first and currently only research centre focusing solely on hydrogen. It built the first hydrogen filling station in Austria, developed the first hydrogen vehicle approved for road use in Austria and the first power-to-gas plant. Today the centre operates a hydrogen refuelling system, several test rigs for electrolysis, fuel cell systems and high-pressure hydrogen up to 1,000 bar. “In autumn 2020, the HyCentA test facility will be expanded by a further 600 square meters to further strengthen hydrogen research in Graz,” says Alexander Trattner.

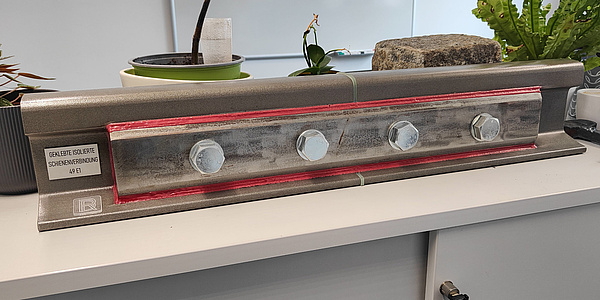

Project HyTrail

In the HyTrail project, the Institute of Railway Engineering and Transport Economy of TU Graz, together with the hydrogen competence centre HyCentA, the University of Leoben, the Johannes Kepler University Linz and the Synergesis company, conducted a comprehensive feasibility study on hydrogen for ÖBB (Austrian railways) from 2018 to 2019. It was examined whether diesel-powered locomotives could be replaced by hydrogen-powered ones. A hydrogen train is already in trial operation on one of the lines investigated.

Hydrogen Corrosion

The transport and storage of hydrogen is also becoming a central issue. Hydrogen can attack metallic materials, causing what’s known as hydrogen corrosion. The very small atom penetrates the material structure, embeds itself and makes the metal brittle. “You often don’t see the deformation for a very long time and suddenly a fatal crack appears,” explains Rudolf Vallant from the Institute of Materials Science, Joining and Forming. Together with his colleagues Andreas Drexler and Hamdi Elsayed, he is researching how hydrogen corrosion occurs and how it can be prevented in the framework of the HISCC UHSS project (Improvement of hydrogen-induced stress corrosion cracking resistance of ultra-high strength steel screws and fasteners). “The corrosion problem was solved in the 1970s for the materials of that time. Today, however, there is a much stronger trend towards thin and high-performance materials, which have completely different load limits compared to materials of the past. So now we have to ask ourselves once again whether these new materials can withstand hydrogen,” says Andreas Drexler, explaining the subject’s renewed topicality.

The researchers developed special corrosion cells for their experiments. In these cells the material is charged with hydrogen and the stress is slowly increased. “An experiment may take several days. So we can measure very precisely what happens at different concentrations of hydrogen.” Finally, their results are to be used in the field of mobility and transport and in the construction of hydrogen pipelines or tanks.

Hydrogen as an Energy Source for the Production of Animal Feed from CO2

Robert Kourist and Bernd Nidetzky have a completely different research approach to the use of hydrogen in a collaboration between the Institutes of Molecular Biotechnology and Biotechnology and Biochemical Engineering. They want to optimize bacteria that use hydrogen to bind CO2, and then chemically extract proteins and amino acids from the bound CO2, which can be used for the production of animal feed. “We want to turn CO2 into foodstuffs, so to speak,” summarizes Kourist. The bacteria currently under investigation grow too slowly and are not sufficiently productive to be used on a large industrial scale. Together with the acib GmbH competence centre (Austrian Centre of Industrial Biotechnology) and the Institute of Biotechnology and Biochemical Engineering, a project has now been launched to investigate and optimize the reactor environment and, at the same time, the bacteria themselves. Furthermore, TU Graz together with acib is participating in the Marie Curie-Sklodowska ITN ConCO2rde, which deals with the biotechnological use of hydrogen. The project leader at the Institute of Molecular Biotechnology is Anita Emmerstorfer-Augustin, and at the Institute of Biotechnology and Biochemical Engineering Regina Kratzer.

Kourist sees great potential for the approach pursued at the Institute: “Hydrogen will be readily available as a raw material source. And once it is cheap enough to run engines, it will also be cheap enough to produce chemicals from it. The future belongs to hydrogen and we want to work on that.”

Anita Emmerstorfer-Augustin of the Institute of Molecular Biotechnology and Regina Kratzer of the Institute of Biotechnology and Biochemical Engineering.

ConCO2rde

ConCO2rde is a project within the Marie Skłodowska-Curie ITN Initiative. The aim of the project is to train young researchers in new technologies for hydrogen use and CO2 utilization. The Institutes of Molecular Biotechnology and Biotechnology and Bioprocess Engineering pursue a holistic concept that includes the optimization of microorganisms and the design of new gas bioreactors.

Versatile Use

The possible applications of hydrogen are manifold. TU Graz Rector Harald Kainz and Alexander Trattner, head of the hydrogen competence centre HyCentA, are also convinced of its value. In October, they jointly advocated higher investments in hydrogen-related research and requested “hydrogen billions” from the Austrian government. “We need hydrogen to be able to realize new forms of energy and to convert our energy systems on a large scale,” summarizes Trattner.

Whether the path to a green future without detours is possible is not yet clear for Viktor Hacker: “At present, there is not yet enough electricity from renewable energy sources to be able to store and use energy in the form of hydrogen on a nationwide basis.” Detours via so-called blue or turquoise hydrogen are conceivable. Although hydrogen will continue to be produced from fossil energy sources, the CO2 will be split off and the emissions will thus be significantly reduced. “This is a very interesting approach and can help to bring important technologies into society. But our goal is of course green hydrogen from 100 per cent renewable energies.”

H2GreenTech

In order to achieve this goal Hacker and his working group initiated the H2GreenTech project in 2020, which aims to promote cross-border cooperation in hydrogen research between Slovenia and Austria and between science and industry.