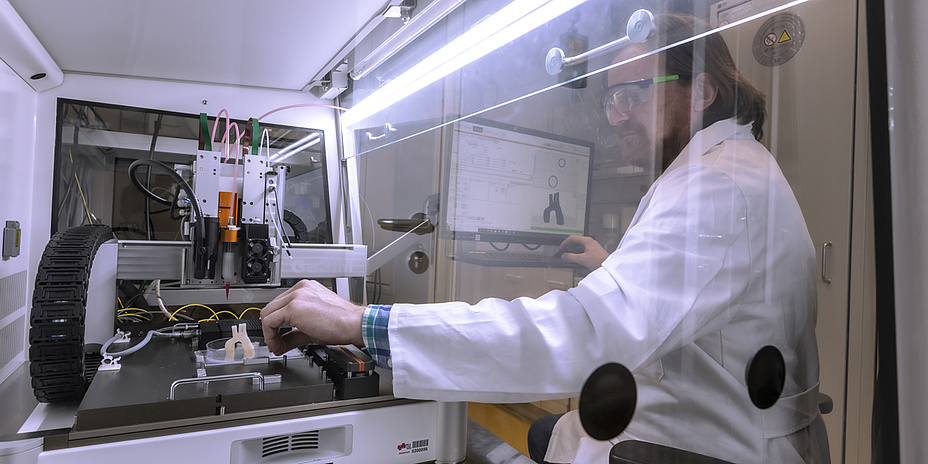

Artificial Tissue from the 3D Bioprinter

"Printing basically works like decorating a cake," says Rupert Kargl, a researcher at the iBioSys Lab of the Institute of Chemistry and Technology of Biobased Systems at Graz University of Technology (TU Graz), explaining how the new bioprinter works. This is a special type of 3D printer. 3D printers basically all work in the same way: "It's all about automatically distributing material in threedimentional space." This activity is usually performed by a robot arm or a lightbeam that is moved in the x, y and z directions. How the material is consolidated in place varies. In the case of the bioprinter at TU Graz, it is a nozzle that processes soft or melted pastes – similar to a piping bag used to create artistic flowers or ornaments on a cake. But instead of icing and marzipan, the bioprinter processes other renewable and organic materials. And instead of flowers, it conjures up vascular walls or artificial skin, for example.

Unique in Austria

"Living tissue is an extremly complex mix of materials," explains Kargl. "Our printer therefore also allows us a lot of flexibility and combination options." The printer can process up to five different materials in one print layer and is, according to the researchers, unique in Austria in this way. In addition to different materials, the plan is to use the printer to attach living cells that can then build new tissue on their own. "For example, we can grow artificial skin."

Gelatin illustrates how chemically modified organic raw materials can be used. It consists of shortened collagen chains and is obtained from animal tissue. It can then be used for cooking on the one hand, but also to simulate skin tissue with the 3D printer. "In terms of stretchability and softness, gelatin has similar properties to human skin if the water content is controlled," Kargl explains.

The printer, the BioScaffolder BS 3.2, enables highest flexibility in the material mix, and the sophisticated software allows a precise application of material: "We can control and fill each voxel – each pixel in the volume – individually," says Kargl.

Strong cooperation partners sought

The bioprinter plays a major role in several projects at the institute. Kargl and his colleagues are currently working on printing models of human blood vessels, for example, which can be used in medical teaching and surgical planning. Most of the researchers at the institute come from materials science and chemistry, so they are looking to bring expertise from the fields of medicine and biology on board. "It's very important for us to have strong collaborative partners with whom we can do joint research projects," says Kargl, who is emphatic that the institute is "always on the look-out for research partners."

This research area is anchored in the Field of Expertise “Advanced Materials Science”, one of five strategic foci of TU Graz.

You can find more research news on Planet research. Monthly updates from the world of science at Graz University of Technology are available via the research newsletter TU Graz research monthly.