In the Turbo-machinery Laboratory at TU Graz

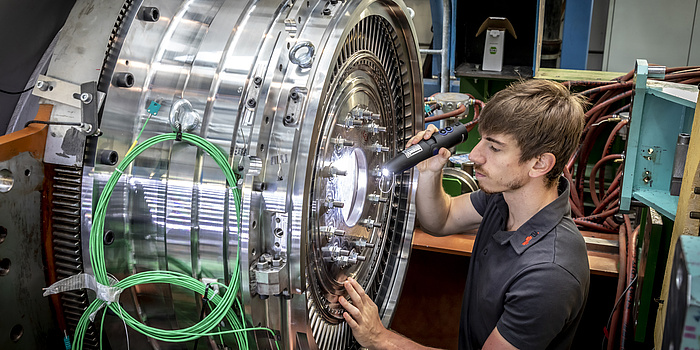

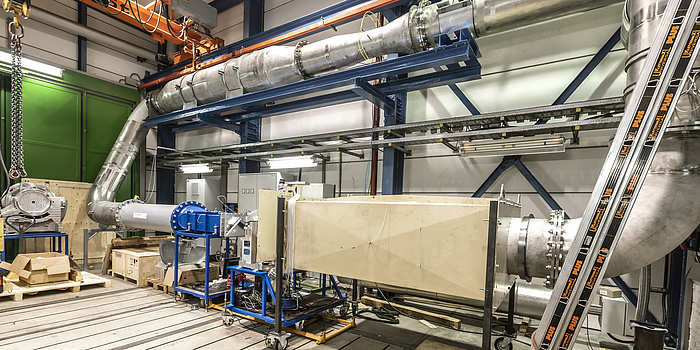

In the transonic test turbine facility, the inflow conditions in an aircraft engine can be realistically simulated from take-off to landing at around 60° to 80° Celsius. This allows the turbine centre frame to be tested under realistic operating conditions. The turbine centre frame is the transition duct between the high-pressure and low-pressure turbine, which is located downstream of the combustion chamber and is one of the hot gas path components of a turbine.

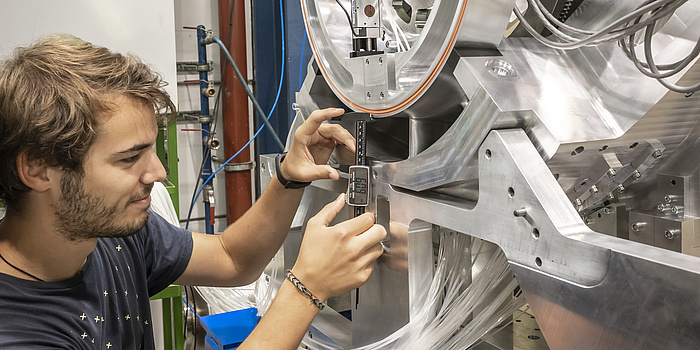

A wind tunnel installed in 2020 is used for preliminary tests on blade cascades. In a turbine, several blades are placed next to each other, which then transport the air. The blade cascade is kept static in the test rig and air flows through it. “We recreate the inflow conditions behind the turbine using spe¬cially made metal screens,” explains Göttlich. This makes the test rig much less complex to operate and, above all, much safer than other test rigs where moving components are tested. Promising blade geometries are investigated in the wind tunnel, and these are then tested in the transonic test turbine facility.

In addition to the transonic test turbine facility and a wind tunnel for blade cascades, the Institute operates a ring grid cascade – a specially designed transonic cascade – which also works with static inflow, but requires the same amount of air and thus the same amount of electricity as the test turbine. With a second test turbine – the subsonic test turbine facility – the stage at the very end of the engine is checked not only for aerodynamics but also for acoustics and blade vibrations. And in the hot-flow test facility, the combustion chamber of the engine is also examined.

The results achieved at Graz are implemented in civil aviation. “The turbines that we are investigating are used in the planes that you and I fly in on holiday,” explains Göttlich.

This research area is anchored in the Field of Expertise “Mobility & Production”, one of five strategic foci of TU Graz.

You can find more research news on Planet research. Monthly updates from the world of science at Graz University of Technology are available via the research newsletter TU Graz research monthly.