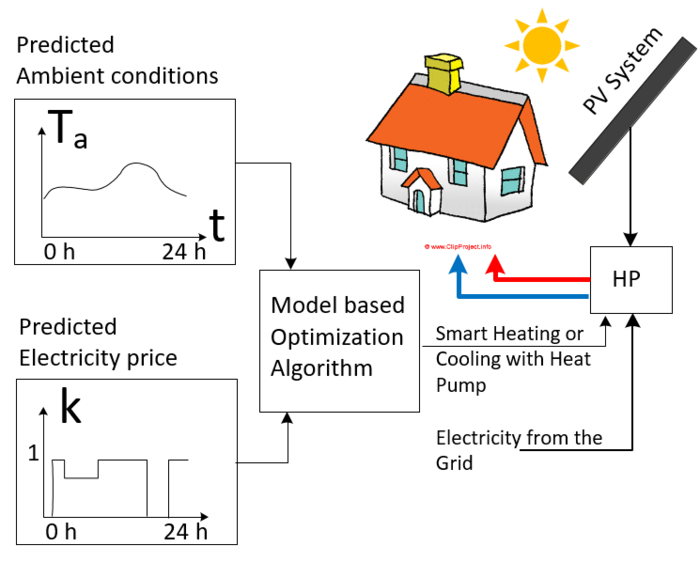

Model predictive control of a heat pump.

Absorption Heat Pumps

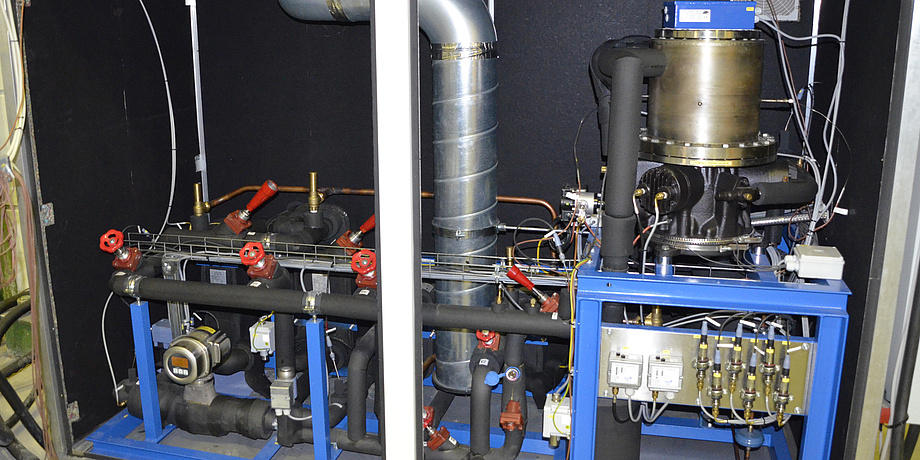

Recently, thermally driven absorption heat pumps have experienced a renaissance. Instead of electricity, this heat pump type uses heat at a rather high temperature (around 80 to 150°C) as driving energy. Today, for example, they are regarded as the successors to condensing boilers, which have been exhausted in terms of efficiency, and gas-fired absorption heat pumps are expected to reduce gas consumption by 40%. Together with a well-known boiler manufacturer, the Institute of Thermal Engineering is working on the simulation¬based optimisation of gas-fired ammonia/water absorption heat pumps (see Figure 2), which are specifically designed as a retrofit option for existing buildings with natural gas infrastructure.

Gas-driven absorption heat pump.

Industrial applications

The industry offers a huge potential for saving energy and thus greenhouse gas emissions. Especially the use of heat pumps for waste heat recovery or as a replacement for gas boilers is gaining in interest. However, a major challenge is the required temperature level, which is typically above 80°C, and this cannot be achieved with conventional systems. In cooperation with the Styrian refrigeration and heat pump manufacturer Frigopol, the Institute of Thermal Engineering is working on the project "HotCycle" which deals with a high¬temperature heat pump using the environmentally friendly refrigerant R600 (butane) providing heat-sink temperatures above 100°C (see Figure 3).E-Mobility

In electrical vehicles (hybrid and electric cars) in particular, heating the passenger compartment is challenging because in these vehicles little or even no waste heat from an internal combustion engine is available. That is why electric direct heating (i.e. resistance heating) is often used in electric vehicles, which means a significant load for the vehicle's battery and thus drastically reduces the cruising range. An interesting possibility is to use the refrigerant circuit of the air conditioning system in reverse operation, i.e. as a heat pump, and this significantly reduces the energy consumption compared to electric direct heating. It has been shown that the annual energy consumption for heating and air¬conditioning can be reduced by up to 40% with a refrigerant cycle using the environmentally friendly refrigerant R744 (CO2). Figure 4 shows an electric vehicle equipped with such a system, which was analysed experimentally in the climatic chamber.

Electric vehicle with reversible R744 a/c system in the climatic chamber.