Modelling and simulation of sheet metal and bulk forming processes

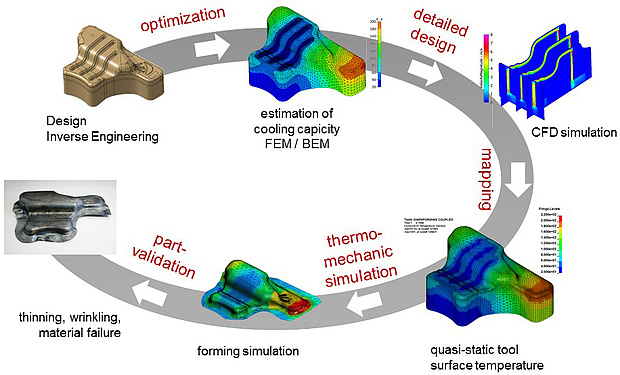

In research and also industrial production the numerical simulation has been established as an indispensable tool for planning, analysis and optimization of forming processes. Geometries and properties of formed parts can be virtually predicted by the software. The aim is to guarantee the manufacturability of formed parts and to optimize the design of the tools by a specific variation of the process parameters or the geometric shape of the tools in the simulation.

Contact

Institute of Materials Science, Joining and Forming

Research Group of Lightweight and Forming Technologies

Inffeldgasse 11/I

8010 Graz

Tel.: +43 (0) 316 / 873 - 9441

Fax: +43 (0) 316 / 873 - 9442

office.lft@TUGraz.at