Laser Metal Deposition

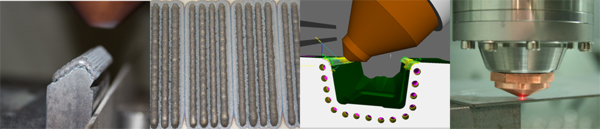

Laser Metal Deposition is used to create metal claddings on existing metal parts and tools. Our Trumpf DMD 505 is based on a NC machine with 5 axes. The metallic substrate is melted by a CO2 laser beam. A nozzle is used to provide a metal powder which is cladded on the substrate in an inert atmosphere. With this technique it is possible to create coatings with different properties regarding surface hardness and wear resistance. The height of the finished surface, after machining, can vary between a few 1/10 mm to several millimeters. Laser Metal Depostion can significantly reduce the wear of tools and therefore increase its durability and, as a result, lower the costs. Furthermore, it is also possible to repair worn out tools instead of acquiring new ones.

Contact

Institute of Materials Science, Joining and Forming

Research Group of Lightweight and Forming Technologies

Inffeldgasse 11/I

8010 Graz

Tel.: +43 (0) 316 / 873 - 9441

Fax: +43 (0) 316 / 873 - 9442

office.lft@TUGraz.at