Bending Technologies

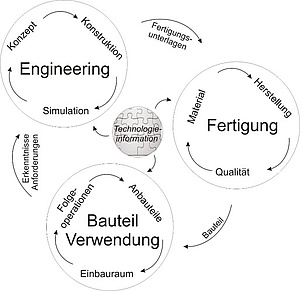

Air bending is a highly flexible manufacturing process for producing three-dimensional parts from flat sheet metal blanks. Only the precise knowledge of all influencing parameters of the overall free bending process during part production (see figure: workflow for air bending) allows the reproducible production of high quality components without long setup times. A suitable prediction of all necessary process parameters reduces waste and cycle times and increases the cost effectiveness of the production at the same time. At the Institute of Tools and Forming a bending machine (TruBend 7036 Trumpf on current technology with electric torque drive) is available for research. figure: Workflow for air bending

figure: Workflow for air bending

Contact

Institute of Materials Science, Joining and Forming

Research Group of Lightweight and Forming Technologies

Inffeldgasse 11/I

8010 Graz

Tel.: +43 (0) 316 / 873 - 9441

Fax: +43 (0) 316 / 873 - 9442

office.lft@TUGraz.at