A Vision-Guided Wood Feeding Crane

The objective of BioChipFeeding is to develop a new wood chip feeding system of the future for small-scale heating plants. A core component of the system is a gripper which enables feeding from above the pile of stored fuel. It will be equipped with sensors to screen the fuel quality regarding particle size and moisture content and thereby have the ability to create a rather constant fuel quality by producing appropriate fuel blends. A core task in the screening process is the optical evaluation of fuel parameters such as particle size and ash content. Another vital aspect is reliable localization of larger patches of fine-grained fuel, overly large objects, and foreign matter in order to maintain a high reliability of the feeding process and heating plant.

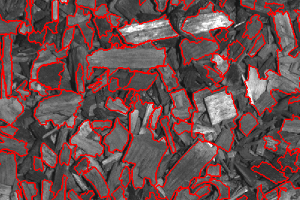

Illuminating the scene from different angles and overexposing the images creates cast shadows at particle boundaries. Fusing these images allows for easy particle segmentation using a watershed approach. Spilling of particles into another along directions normal to the baseline of two light sources can be mitigated by restricting the particle segmentation to star-convex shapes. Metric information of particle sizes is obtained either by triangulation using a stereo camera setup or, if a more coarse estimation is sufficient, by leveraging the distance measurement of a ultrasonic rangefinder.

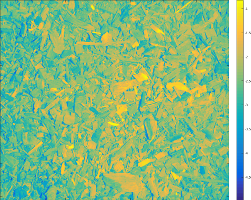

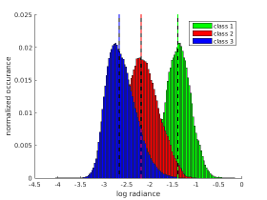

Depending on the load of the heating plant it may be feasible to avoid feeding fuel with high ash content. High ash content is usually associated with a large proportion of bark in the fuel and thus can be tied to the radiometric intensity. A reliable estimate for the scene radiance independent of changes in ambient light is obtained by acquiring a HDR seuqence with illumination dominated by the LED light sources. Based on the HDR histogram of the scene, the fuel is classified into predefined fuel classes.

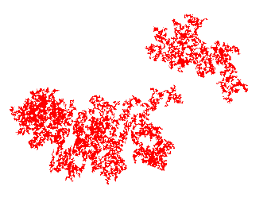

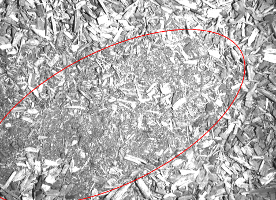

Sawdust as well as overlarge particles may obstruct the screwfeeder leading to unexpected shutdowns of the heating plant. Both cases are detected by exploiting statistics of the image segmentation obtained for particle size evaluation. The respective areas in the fuel depot then can be avoided when feeding the plant and later can be removed at a time when the gripper would idle otherwise.

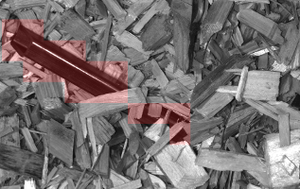

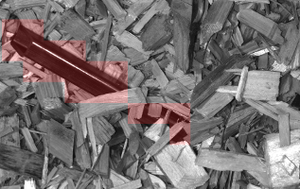

In the various steps from wood chip production until delivery to the fuel depot of the heating plant unnoticed contamination with foreign particles may occur. Again, these particles pose a threat of obstructing the feeder screw or the grate in the furnace, leading to unexpected plant shutdown. Employing an abnormal event detection framework with sparse dictionary learning methods, foreign matter on the surface of the fuel pile is detected and allows for an automatic removal from the fuel depot.

Contact: Ludwig Mohr, Matthias Rüther

In the various steps from wood chip production until delivery to the fuel depot of the heating plant unnoticed contamination with foreign particles may occur. Again, these particles pose a threat of obstructing the feeder screw or the grate in the furnace, leading to unexpected plant shutdown. Employing an abnormal event detection framework with sparse dictionary learning methods, foreign matter on the surface of the fuel pile is detected and allows for an automatic removal from the fuel depot.

Contact: Ludwig Mohr, Matthias Rüther

Particle Size Evaluation

|  |

Ash Content Estimation

|  |

Detecting Sawdust and Overlarge Objects

|  |

Foreign Object Detection

In the various steps from wood chip production until delivery to the fuel depot of the heating plant unnoticed contamination with foreign particles may occur. Again, these particles pose a threat of obstructing the feeder screw or the grate in the furnace, leading to unexpected plant shutdown. Employing an abnormal event detection framework with sparse dictionary learning methods, foreign matter on the surface of the fuel pile is detected and allows for an automatic removal from the fuel depot.

Contact: Ludwig Mohr, Matthias Rüther

In the various steps from wood chip production until delivery to the fuel depot of the heating plant unnoticed contamination with foreign particles may occur. Again, these particles pose a threat of obstructing the feeder screw or the grate in the furnace, leading to unexpected plant shutdown. Employing an abnormal event detection framework with sparse dictionary learning methods, foreign matter on the surface of the fuel pile is detected and allows for an automatic removal from the fuel depot.

Contact: Ludwig Mohr, Matthias Rüther

Robot Vision

News

2016/12/16: New Open Student Position: LIDAR Metrology Tooling

--> Learn More2016/12/01: New Open Student Position: Robotic Charging of Electric Vehicles

--> Learn More2016/07/15: Accepted to BMVC 2016

Our paper "A Deep Primal-Dual Network for Guided Depth Super-Resolution" has been accepted for oral presentation at the British Machine Vision Conference 2016 held at the University of York, United Kingdom.

2016/07/11: Accepted to ECCV 2016

Our paper "ATGV-Net: Accurate Depth Superresolution" has been accepted at the European Conference on Computer Vision 2016 in Amsterdam, The Netherlands.

2015/10/07: Accepted to ICCV 2015 Workshop: TASK-CV

Our paper "Anatomical landmark detection in medical applications driven by synthetic data" has been accepted at the IEEE International Conference on Computer Vision 2015 workshop on transferring and adapting source knowledge in computer vision.

2015/09/14: Camera calibration code online

The camera calibration toolbox accompanying our paper "Learning Depth Calibration of Time-of-Flight Cameras" is available here.

2015/09/07: Accepted to ICCV 2015

Our papers "Variational Depth Superresolution using Example-Based Edge Representations" and "Conditioned Regression Models for Non-Blind Single Image Super-Resolution" have been accepted at the IEEE International Conference on Computer Vision 2015, December 13-16, Santiago, Chile.

2015/07/03: Accepted to BMVC 2015

Our papers "Depth Restoration via Joint Training of a Global Regression Model and CNNs" and "Learning Depth Calibration of Time-of-Flight Cameras" have been accepted as a poster presentation at the 26th British Machine Vision Conference, September 7-10, Swansea, United Kingdom.