MOSH MOAH Cutting System

The analysis of mineral oil hydrocarbons contamination in food and food contact materials is an emerging issue in the last years. There are several sources for possible contamination throughout the whole production chain from raw material to the packed good.

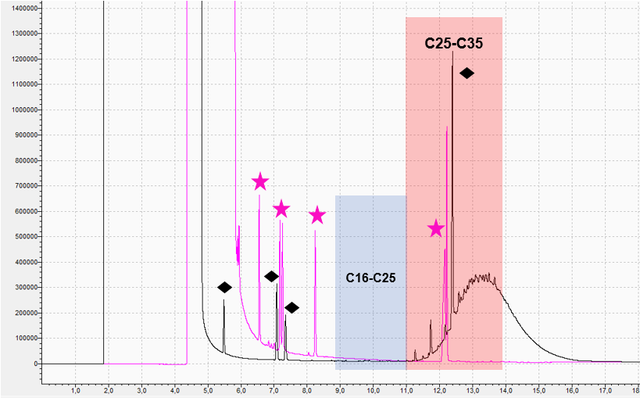

Due to their chemical structures mineral oils can be divided into two fractions: Mineral oil saturated hydrocarbons (MOSH) consist of linear and branched alkanes, and alkyl-substituted cyclo-alkanes, whilst mineral oil aromatic hydrocarbons (MOAH) include mainly alkyl-substituted polyaromatic hydrocarbons. The MOSH can accumulate in the human body and cause granulomas1,2, the MOAH which makes up 15-30% of the whole mineral oil fraction may contain potential mutagenic and carcinogenic substances2,3. At the moment there are no legal limit in Europe for MOSH/MOAH, but MOSH concentrations up to 2 mg/kg and MOAH levels below 0,5 mg/kg are considered to be acceptable.

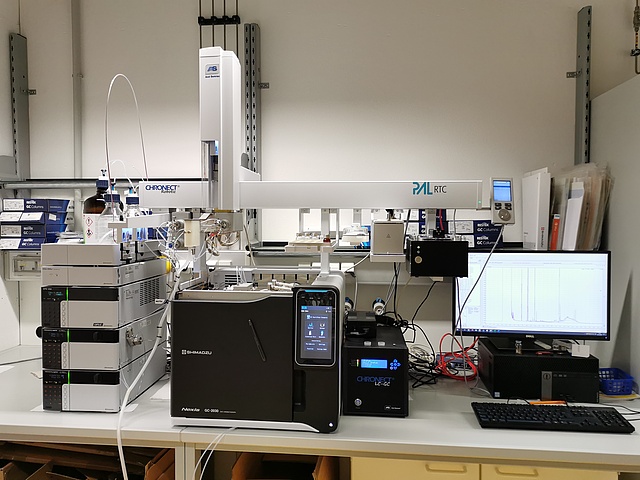

The analysis of MOSH and MOAH is a big challenge due to its really complex composition of unresolved and unidentified substances and the formation of irregular humps. The method of choice uses on-line coupling of liquid chromatography with gas chromatography and flame ionisation detection (HPLC-GC-FID; see Fig.1)4,5. The information generated by this analysis method is the total amount of MOSH and MOAH.