Characterisation of Functional Barriers for Food Contact Materials

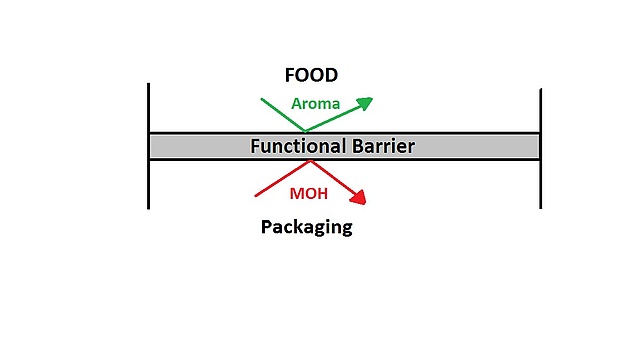

Food contact materials are materials or articles that are considered to come into contact with food. They should not release substances into food that change the properties of the food or pose a potential risk for human health. Examples for FCMs include machinery to process food, kitchenware, tableware and packaging materials, (e.g. paper, board, and plastics) 1. The packaging should on the one hand protect the packed good from unwanted changes by e.g. air, light or oxygen and stop migration of unwanted substances from the environment or from the packaging itself (e.g. non-intentionally added substances (NIAS), mineral oil hydrocarbons…). On the other hand it should preserve the quality and taste of the food.

Recycled paper and board are one of the most often used food packaging material at the moment, due to the lightness of the material, the cheap price, the biodegradability and the save of resources by recycling. The disadvantages are that paper and board are no barriers against the above mentioned substances and due to the recycling process the fibres and the resulting packaging are contaminated with unwanted substances, including e.g. mineral oil hydrocarbons. Therefore, paper and board are coated with so called functional barriers to improve the barrier properties of the packaging and fulfil the above mentioned requirements as well as statutory requirements. At the moment materials used are synthetic materials like poly ethylene or poly propylene, silicones, waxes or aluminium. They have the big disadvantage that the resulting packaging is not biodegradable anymore and recycling is- if possible- really difficult 2,3.

Aim of this project is the development of bio based or at least biodegradable functional barriers for food contact materials that fulfil the requirements mentioned above. Possible materials include micro-, or nanocrisalline cellulose, chitosan or alignate. On the analytical side, new methods for the characterisation of functional barriers and food contact materials should be developed. In addition, the new methods, as well as the actually existing ones, should be applied on the developed materials.

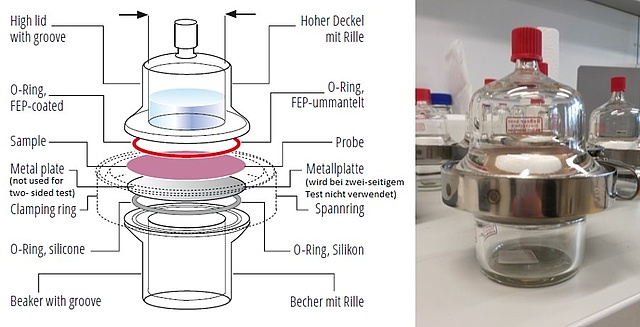

One of the methods actually used is the Tenax-Migration4. The storage of packed food is simulated with the food simulant TenaxTA (Poly(2,6-diphenyl)-p-phenyleneoxide), which is a simulant for dry food like rice or flour. This simulation is done in special cells called „MigraCell“. A scheme of the cell and a used cell could be seen below.

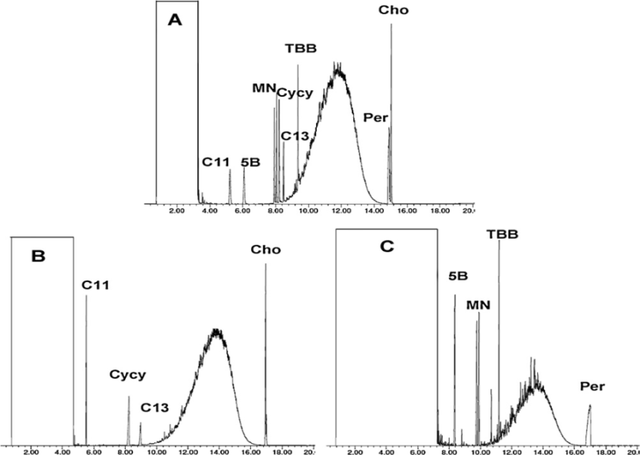

The sample is placed between the beaker and the high lid, the cell is closed and the sample covered with Tenax. The storage of a food sample in the packaging is simulated at defined time at elevated temperature (e.g. 10 days at 60°C)4. Afterwards the migrated substances are extracted from the Tenax and the extract analysed using gas chromatography with mass spectrometry or gas chromatography with flame ionisation detection to qualify and quantify the migrated substances and to determine the overall migration from the packaging into the food simulant. Besides the overall migration this cell could also be used to determine gas phase permeation from one side of the packaging (outside, environment; two-sided test) to the other (inside, food; simulated by tenax), which gives information about the barrier properties of the tested materials. The disadvantage of this method is the high workload and consume of time.

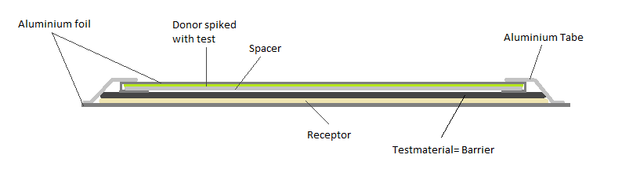

New methods were the barrier is wrapped with a donor and acceptor into test packs are investigated by several authors6,7. The donor is spiked with substances that are potential migrates from the packaging through the barrier to the food or vice versa. The barrier should prevent the migration to the receptor, which collects the migrated substances. From the collector stripes are cut off periodically, extracted and analysed using GC-MS with liquid injection to determine the amount of migration.

At the moment one of the biggest problems of paper and board packaging are the migration of mineral oil hydrocarbons from the packaging into the food. Mineral oil hydrocarbons (MOH) are divided into a saturated fraction and an aromatic fraction. The mineral oil saturated hydrocarbons (MOSH) consist of branched and unbranched open chain hydrocarbons called paraffines and cyclic hydrocarbons with at least one saturated ring called naphthenes. They can accumulate in the human body and cause granulomas8,9. The mineral oil aromatic hydrocarbons (MOAH) consist of aromatic substance classes, that can be highly alkylated and have 1-4 rings. They make up 15-30% of the whole mineral oil fraction and contain potential mutagenic and carcinogenic substances10,11. There are no EU-regulations and no approved analysis method so far. Typical mineral oil concentrations in food are e.g.12:

The analysis of MOH is a big challenge due to its really complex composition of unresolved and unidentified substances. Recently a proposed method uses liquid chromatography coupled with gas chromatography and flame ionization detection (HPLC-GC-FID)6. The advantage of this method is the “identical” response to all classes of hydrocarbons received from the FID, but it lacks on specific information. The only information generated by this analysis method is the total amount of MOH. Therefore, in this project new analytical approaches for the determination and further characterisation of MOH using multidimensional methods shall be developed (e.g. two dimensional comprehensive GC×GC-MS after HPLC separation).

| Edible oil | up to 6000 mg/kg |

| Bakery products | max. 2800 mg/kg |

| Products stored in jute bag (rice, coffe, cocoa) | nn- ~500 mg/kg |

| chocolate | 5-1300 mg/kg |

| Fish (related to fat content) | 10-1200 mg/kg |

| Baby food (packed in paperboard) | up to 33 mg/kg |

The analysis of MOH is a big challenge due to its really complex composition of unresolved and unidentified substances. Recently a proposed method uses liquid chromatography coupled with gas chromatography and flame ionization detection (HPLC-GC-FID)6. The advantage of this method is the “identical” response to all classes of hydrocarbons received from the FID, but it lacks on specific information. The only information generated by this analysis method is the total amount of MOH. Therefore, in this project new analytical approaches for the determination and further characterisation of MOH using multidimensional methods shall be developed (e.g. two dimensional comprehensive GC×GC-MS after HPLC separation).

In summary, this project deals with functional barriers for food contact materials. Functional barriers are placed between packaging and food to prevent migration of unwanted substances into the food and to prevent unwanted changes of the food itself. Aim of the project is it, to develop bio based or at least biodegradable barriers for FCMs to eliminate the problems of e.g. recycling from synthetic materials. The barriers are tested with actually existing methods and new quicker and more sensitive methods should be developed and applied to the problem. The second part of the project focuses on mineral oil hydrocarbons, possible source and the use of multidimensional methods to gain a greater extent of information.

References:

- European Commission (2015), doi: 10.2875/6815.

- Richter, L., et al. Eur Food Res Technol. 239 (2014), 125-225.

- Ewender J., Franz R. and Welle, F. Packaging Technology Science, 26, (2013). 423–434

- Commission Regulation (EU), No 10/2011. Official Journal of the European Union. 14 January 2011.

- Source of scheme: https://www.fabes-online.de/media/Migracell_FABES.pdf

- Fisilier, K. et al. Packag. Technol. Sci. (2011), 285-301.

- Biedermann-Brem, S. et al. Packag. Technol. Sci. (2016), 75-89.

- Vollmer, M. et.al. Eur Food Res Technol , 232 (2011) 175-182.

- Moret S., et. al. Food Chem 157 (2014) 471-475.

- Lorenzini R., et.al. Food Addit Contam 30 (2013) 760-770.

- Fisilier K. et. al. J. Chromatogr. A. 1271 (2013) 192-200.

- EFSA Journal (2012) 10(6):2704