The world of gas bubbles and liquid drops

On the one hand, it is exactly these kinds of bubble processes we are investigating – in other words how gas bubbles behave in viscoelastic liquids. But we also deal with exactly the opposite. In other words, how drops of liquid behave in a gaseous environment, as is the case in atomisation processes in the formation of sprays, for example.

We are surrounded by gases and liquids. And how exactly they behave is investigated in the research field of fluid dynamics. This field is subdivided into aerodynamics, i.e. the science of the motion of air, and hydrodynamics, for the behaviour of liquid materials. Liquid materials can be Newtonian or non-Newtonian, and each of them has a different respective dynamic behaviour. The behaviour of Newtonian liquids, as for example water, can be described using a simple material law. For non-Newtonian liquids, as for example viscoelastic liquids, the material law is more complicated. These liquids change their material behaviour under the action of forces: some of these liquids become thinner, whereas others become thicker. If the force is exerted slowly, then some non-Newtonian materials behave like liquids, whereas, if the force is exerted more quickly, they behave like solids. Examples of viscoelastic liquids are blood and gels, but also solutions of polymers and proteins. Materials with viscoelastic properties occur frequently in bio-process engineering. To bring about reactions in these liquids, for instance by means of bacteria or algae, the liquids are aerated with oxygen. The success of these reactions essentially depends on how long the gas bubbles remain in the liquid before leaving it. This residence time of the gas bubbles depends on their rise velocity and on the depth of the liquid bath. ‘On the one hand, it is exactly these kinds of bubble processes we are investigating – in other words how gas bubbles behave in viscoelastic liquids,’ says Günter Brenn, explaining his work. ‘But we also deal with exactly the opposite. In other words, how drops of liquid behave in a gaseous environment, as is the case in atomisation processes in the formation of sprays, for example.’

Important questions in fluid dynamics

In principle, gas bubbles rise in a liquid at a certain constant velocity – as we can easily observe in our glasses of drinks. The actual velocity depends on the volume of the bubble: the bigger the bubble, the faster it rises. But this is quite different in viscoelastic liquids. If the volume of a gas bubble exceeds a particular threshold value in some viscoelastic liquids, it rises disproportionately much faster than a bubble with a slightly smaller volume below the threshold. ‘We don’t know exactly why this is so yet, but we have a model in mind that we want to test. Of course, we have a fundamental interest in this – we want to find an explanation for this phenomenon in the interest of basic research,’ justifies Günter Brenn. ‘But such findings are of course very valuable in process engineering’. The aim is to predict the behaviour of one respective material in another, to characterise the respective liquids correctly on the basis of these findings, and finally to use them successfully.Experiments in the labs at Campus Inffeldgasse

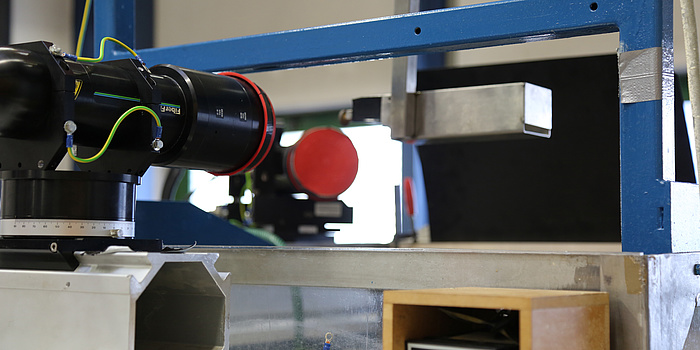

It is mainly experimental work that is carried out in these research areas under Günter Brenn. Test rigs are available in his laboratory on the ground floor of TU Graz’s Institute of Fluid Mechanics and Heat Transfer at Campus Inffeldgasse, as Brenn explains: ‘We systematically produce gas bubbles which we allow to rise in liquids, and we measure this process accurately. And we do this in the same way with atomisation processes. We spray the liquid into the air under controlled conditions and measure the propagation and the size of the drops.’

Nomination for the renowned Balzan Prize

Günter Brenn has been nominated for the Balzan Prize 2018 by the Austrian Academy of Sciences for his work. The highly endowed prize has been awarded once a year since 2001 by the Balzan Foundation in the categories humanities and social sciences, art, physics, mathematics and science, as well as medicine. The respective four specialist fields in these categories change every year – this year prizes will be awarded for social anthropology, global history, fluid dynamics and chemical ecology. At least half of the prize money amounting to 750,000 Swiss Francs has to be invested in research. Should he win the prize, Günter Brenn would like to continue working on the big questions at the centre of his research interest.This project is anchored in the FoE <link https: www.tugraz.at en research forschungsschwerpunkte-5-fields-of-expertise human-biotechnology overview-human-biotechnology _blank int-link-external external link in new>‘Human & Biotechnology’, one of five research foci of Graz University of Technology.

You can find more research news from this field in <link https: www.tugraz.at en tu-graz services news-stories planet-research current-articles _blank int-link-external external link in new>Planet research.

Kontakt

Univ.-Prof. Dr.-Ing. habil.

Institute of Fluid Mechanics and Heat Transfer

Inffeldgasse 25/F

8010 Graz

Phone: +43 316 873 7340

<link int-link-mail window for sending>guenter.brenn@tugraz.at