TU Graz invests in grinding technology

Photographic material available for download at the end of the text.

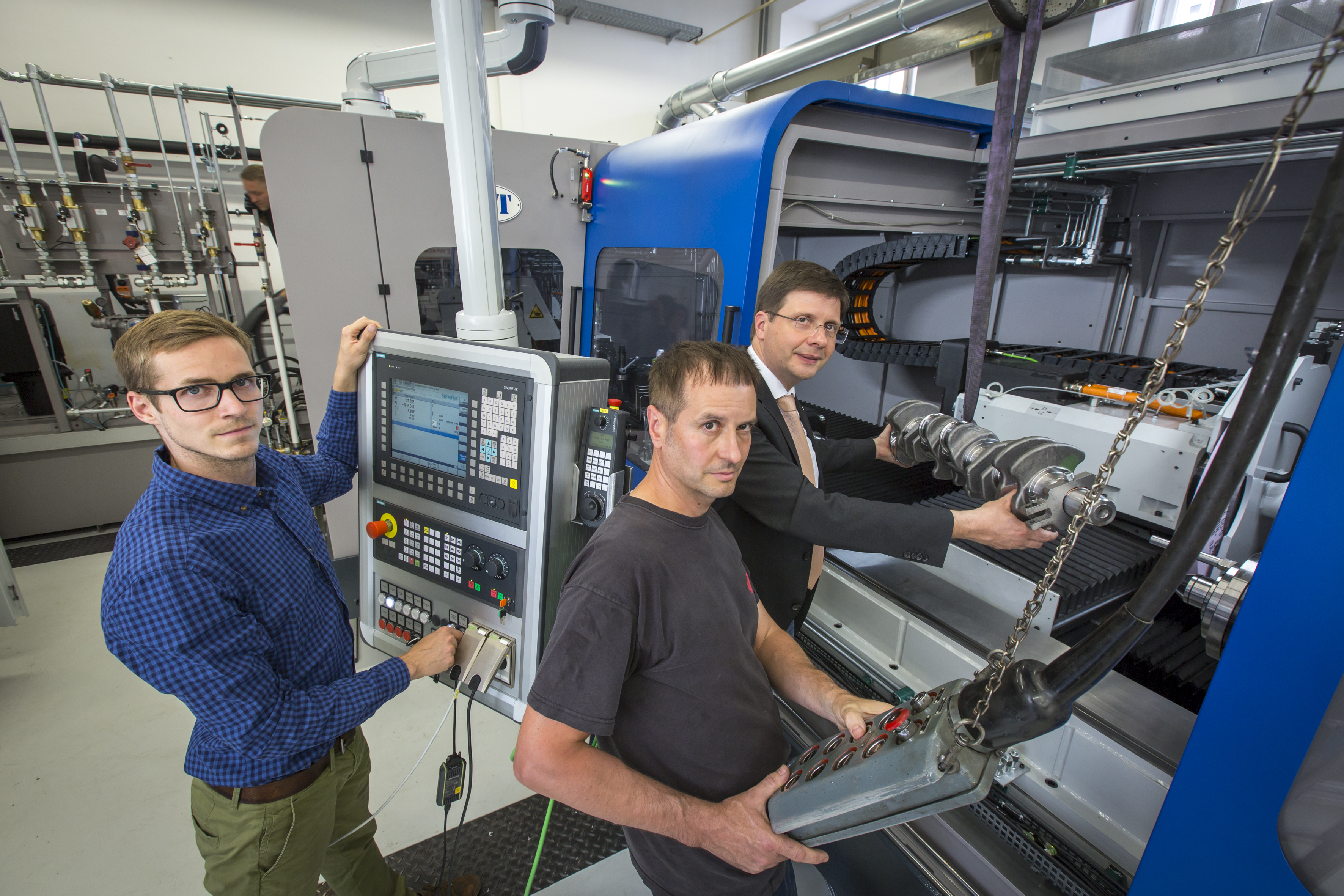

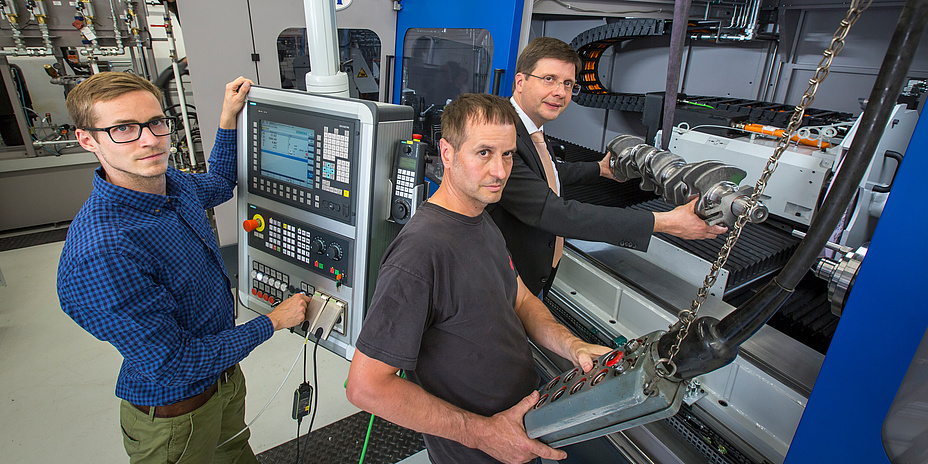

Engine development and production technology at the research location Styria has gained a valuable addition in the form of a new grinding machine for research at the Institute of Production Engineering, TU Graz. “Without suitable manufacturing techniques even the most promising developments are unrealistic,” says Franz Haas, head of the Institute of Production Engineering. His team now have a tailor-made and thus unique grinding machine.

New levels of precision machining

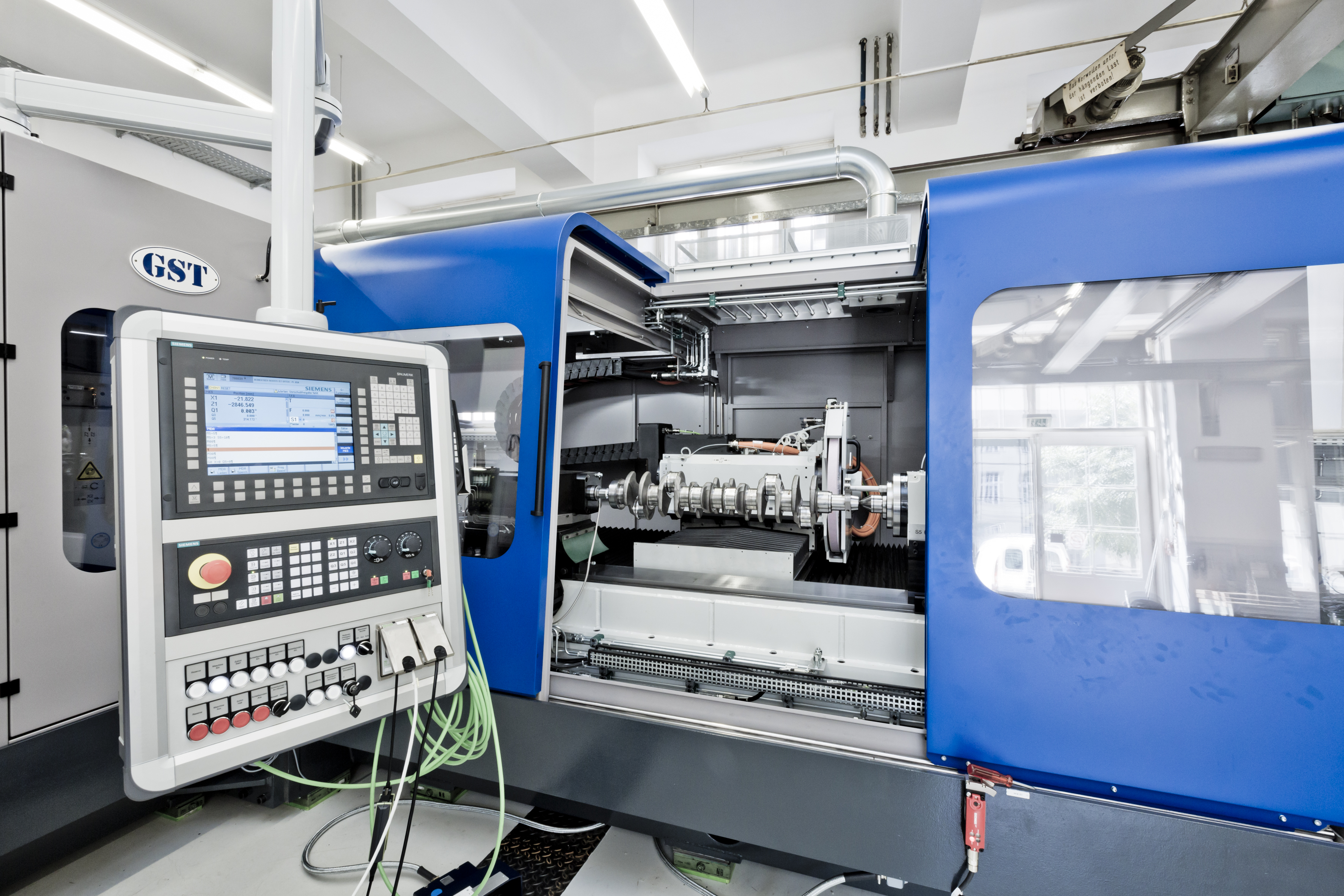

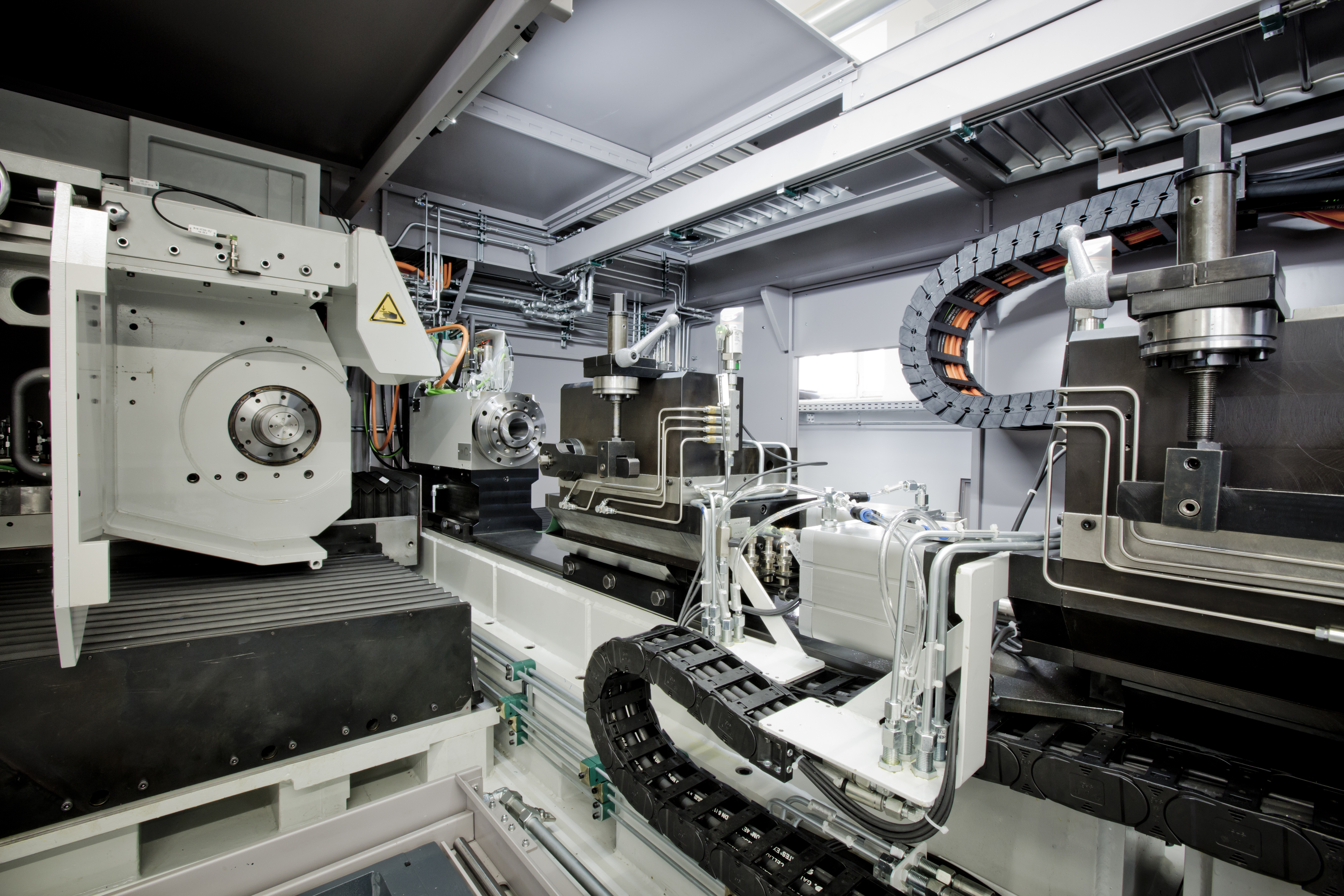

The machine has dimensions of 3.5 x 2.5 x 5.5 metres and a weight of about 40 tons, was designed by the GST company in Lower Austria, and was built with the help of several parts suppliers among which are Siemens – a partner of TU Graz of many years – and the Austrian company Lubot and Framag, and commissioned in the halls of the Institute in Kopernikusgasse. It is equipped with cutting-edge drive and sensor technology and will be used as a practical example for Industry 4.0 in production research. Apart from quality, size and the made-in-Austria seal, it has a distinctive feature: the machine can grind non-circular work-piece profiles, such as camshafts, which control the inlet and outlet valves of an engine. “After some two years of planning and coordinating with GST, we are delighted to be putting the machine into operation. We’ve got a lot of plans for research, from new production processes to significant improvements in process parameters and manufacturing times,” stresses Haas.

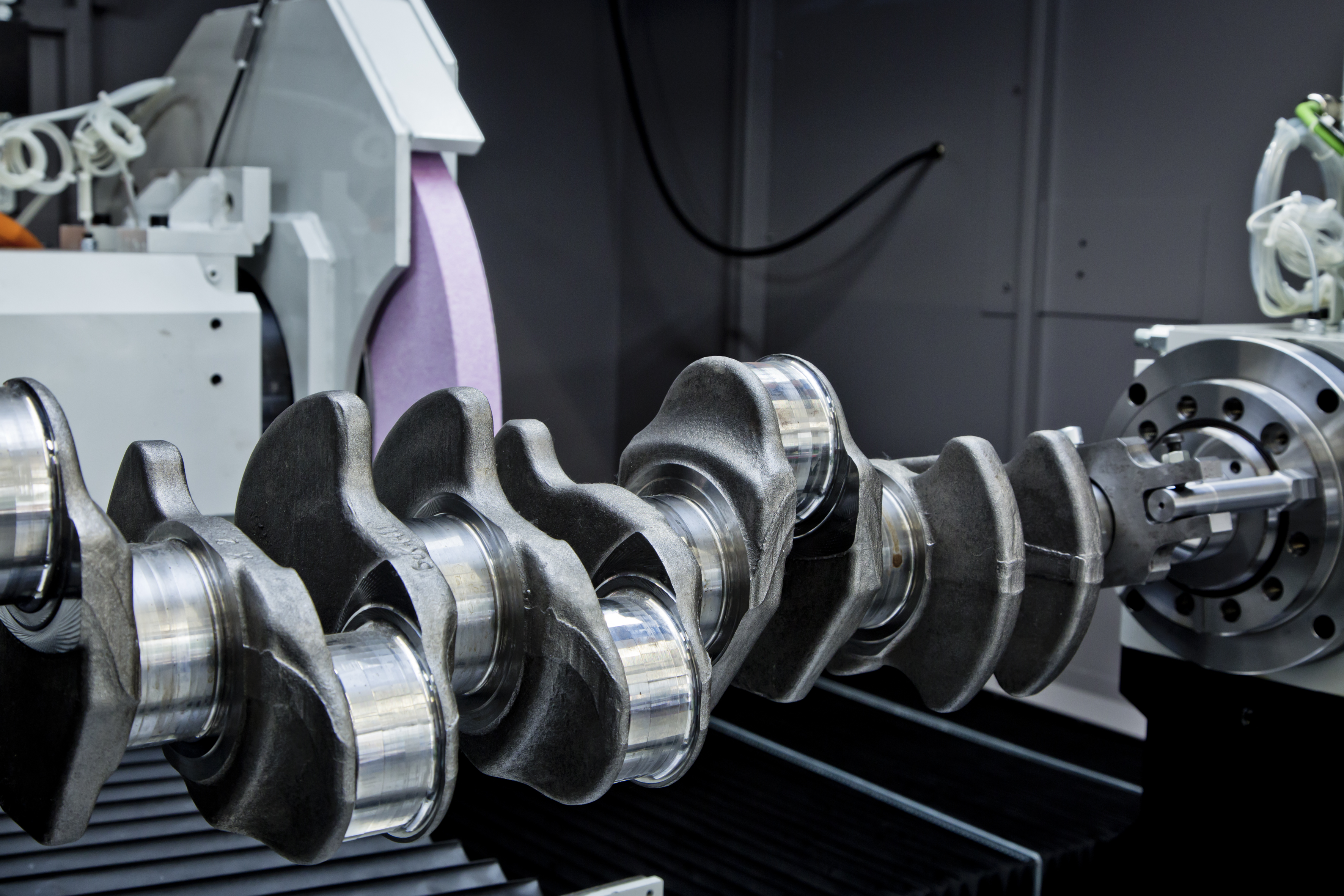

But the spotlight is on precision machining – “finishing” in the production of engines and drive components. Crankshafts are one example – the core component of car engines. They transform pressure into a rotational movement and are statically and dynamically highly stressed parts. “The ground surfaces reduce friction and wear and thus make a crucial contribution to energy efficiency. That’s the focus of our activities, and we also want to use the machine to conduct research on new possibilities of reducing the use of coolants in large grinding machines,” explains Haas. Initial cooperation projects with big automotive manufacturers are in the pipeline, and existing partnerships will be strengthened.

Exhibition for the specialist community

With the conference “Production Engineering Graz 2016”, the team led by Haas will gather together the German-speaking specialist community of production engineering in Graz for the first time in many years. About 80 experts will address themselves to the latest developments in vehicle production, energy-efficient machining, new machining tools and 3D printing using selective laser melting.

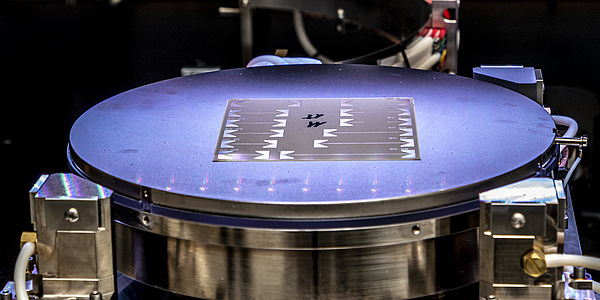

The Institute will also host an exhibition at the conference. Besides the brand new grinder, TU Graz’s metal 3D printer is also at centre stage. A laser beam can selectively melt a fine metal powder and bind with other powder particles – in this way metal parts are generated in any shape, and built up layer upon layer. And the Institute is also proud of another piece of machinery. For about a year the Institute has had a milling and grinding machine with vibration-supported machining, which has been used up to now for precision cutting of ceramic parts – for instance for telescope lenses and tooth implants. Scientists at TU Graz want to apply this technology to metallic materials. All the Institute’s machinery is used in teaching and available to partners from industry for cooperation projects and services.

This research area ist attributed to the Field of Expertise "Mobility & Production“, one of TU Graz' five strategic areas of research.

Kontakt

Franz HAAS

Univ.-Prof. Dipl.-Ing. Dr.techn.

TU Graz | Institute of Production Engineering

Phone: +43 316 873 7170

Mobile: +43 676 432 7691

franz.haas@tugraz.at