Rail4Future is Creating the Future of Rail on the Computer

Where would the future of the railway be in better hands than in a project with the auspicious name of Rail4Future? For the first time, all the important players in the railway industry are working closely together here and opening up a holistic view of the railway system. This is also absolutely necessary if the rail transport of the future is to meet all requirements. And in view of a planned doubling of passenger and freight traffic in Austria by 2040, these requirements are quite high.

Using the most accurate simulation possible, a digital twin, the partners of the FFG-funded COMET project Rail4Future want to find out even before this planned doubling, how the interaction of vehicle and track will be shaped by increased train volumes and which changes in different parameters will have which effects in terms of maintenance, durability and wear. An important success was achieved right at the start of the project in March 2021. Practically all major rail players are on board – from infrastructure to steel construction, track construction, rolling stock construction and mechanical engineering. The fact that they are all also making their highly sensitive data available for the joint project is unique.

Merging vehicle construction and track construction

If this were not the case, the implementation of the project would not be possible. “It’s about matching the different components to each other,” explains Roman Weilguny from the Institute of Structural Durability and Railway Technology at Graz University of Technology (TU Graz). If you roughly divide the railway into the areas of track and rolling stock, then these two sides have had little to do with each other in the past. On one hand, there were the mechanical engineers who developed the vehicles, on the other the civil engineers who took care of the track. And both sides have different approaches to how they calculate things. On the vehicle side, dynamic calculations are made up to very high frequencies, and on the track side, static calculations are more in demand.

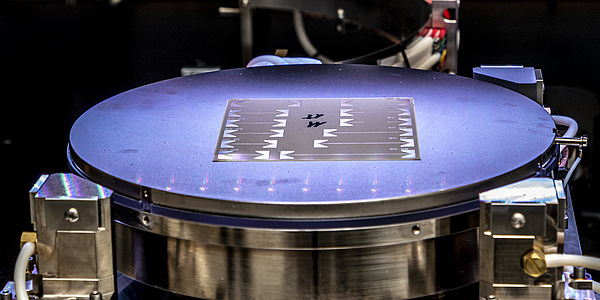

The aim of Rail4Future is to combine these approaches into one system in order to simulate the exemplary track between Bruck an der Mur and Graz as accurately as possible and to find the best way to create a track-friendly vehicle and a vehicle-friendly track. In the computer, a vehicle is created out of individual bodies such as wheels, bogie frame and carriage body to simulate a mass similar to the one in the real world and these parts are then virtually connected with spring and damper elements. Such simulations of rolling stock have been done for several years.

Destructive frequencies

What is new, however, is simulating the track in a similar way. “Actually, the track in the computer is also nothing more than a line for the course of the track and below that I also have spring and damper elements that represent the ballast and the railway sleepers. As soon as the vehicle drives over it, it sinks in a little and then springs out again. And this combination of vehicle and track is what ultimately makes the simulation,” says Roman Weilguny. Any stresses that are initiated at the top of the vehicle also arrive at the bottom, and thus it has already been possible to determine, for example, which frequencies destroy the ballast under the track.

However, the matter is not as simple as it sounds. This is because, despite numerous standardizations in the railway sector, there are still some parameters that cannot simply be standardized. One example is the ballast used in track construction. On the one hand, no two pieces of crushed stone are alike; on the other hand, the characteristics of the crushed stone can vary greatly depending on the mining area. To reliably simulate something like this and derive reliable forecasts from it is therefore an extremely difficult and, above all, computationally intensive undertaking – after all, in reality the gravcel used can differ greatly over just a few metres of track.

Every area has its pitfalls

Ferdinand Pospischil from the Institute of Railway Infrastructure Design at TU Graz is aware of numerous other factors that are difficult to represent with one hundred percent accuracy for the simulation of the entire track between Graz and Bruck an der Mur. “There’s a culvert underneath the track at some point, like a small pipe, and the existing stiffnesses of the substructure are not predictable. Then we have, for example, local temperature differences due to tunnels, bridges and embankments, and there are drainage problems and so on. And so every area has its pitfalls,” says Ferdinand Pospischil. The different ages of different sections of track or of substructure elements such as bridges also play a role here. Nevertheless, Ferdinand Pospischil also recognises the potential that Rail4Future offers. “I think the project will definitely help us in our planning to know more about what we are actually doing and also to predict the future from the point of view of maintenance, wear and tear, and use.”

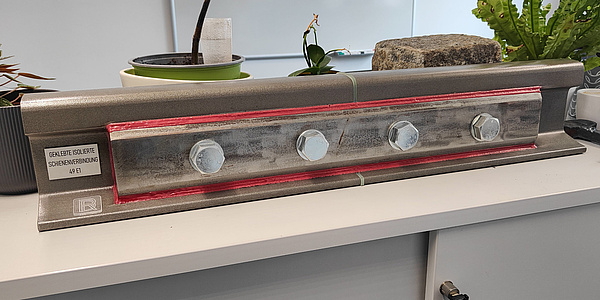

It will be particularly important to be able to digitally predict the effects of changes in the system in advance – for example, if other railway sleeper types and elastic elements are used or if other types of train propulsion are used. Reliable simulation of changes will also speed up the development of new components. Whereas in the past a newly designed part, for example a rail support point, first had to be tested in real operation for years after the development period, this will then be possible digitally. Advantages and disadvantages of the new component are revealed much more quickly this way.

Future forecasts for changed conditions

In view of the future increase in the number of trains, forecasting options are also urgently needed for familiar components. For Stefan Marschnig from the Institute of Railway Engineering and Transport Economy at TU Graz, something like this can only work digitally. Among other things, he specializes in the subject of switch points, which, as a moving part in the track, bring their own unique challenges. With the measurement data collected so far, Stefan Marschnig can estimate how switch points behave with a constant vehicle mix. But that will not be enough for the future.

He also sees the problem of the many parameters that can only be brought into a simulation with difficulty and in any case only with enormous computing power. “We are not simulating the engine of an aircraft, which is a built part. That’s just not possible here. First, everything is outside. Secondly, the track is as it is. Every railway sleeper is different. Below is ballast, which is a natural product. We can’t say that we know exactly how every grain of ballast behaves,” says Stefan Marschnig. But despite these limitations, he sees the benefits of Rail4Future, especially when it comes to looking at developments for the entire rail network. “What happens when there are many more trains? This is something that needs to be considered in a much broader way. We will make this knowledge available.”

A lecture for all sides

Rail4Future also widens this broader perspective at TU Graz itself. The project has considerably intensified the exchange between the three participating institutes. In the meantime, a new joint lecture has even been created. Under the title “Measuring, Monitoring & Design in the Railwaysystem”, lecturers from the Institutes of Railway Infrastructure Design, of Structural Durability and Railway Technology as well as of Railway Engineering and Transport Economy shed light on all sides of railway construction – in this way Rail4Future has also opened up completely new approaches to the subject of railways here.

This article is part of the TU Graz dossier "On track: What does tomorrow's railroad need?". Would you like to receive the latest stories, news, research stories, interviews or blog posts from TU Graz directly on your smartphone or in your email inbox? Subscribe to the TU Graz Telegram newsletter free of charge.

Kontakt

Stefan Marschnig

Assoc.Prof. Dipl.-Ing. Dr.techn.

TU Graz | Institute of Railway Engineering and Transport Economy

Mobile: +43 664 60 873 6717

Email: stefan.marschnig@tugraz.at

Ferdinand Pospischil

Univ.-Prof. Dr.techn.

TU Graz | Institute of Railway Infrastructure Design

Mobile: +43 664 8 889 2190

Email: ferdinand.pospischil@tugraz.at