Modelling for optimising the properties of paper

Made for each other

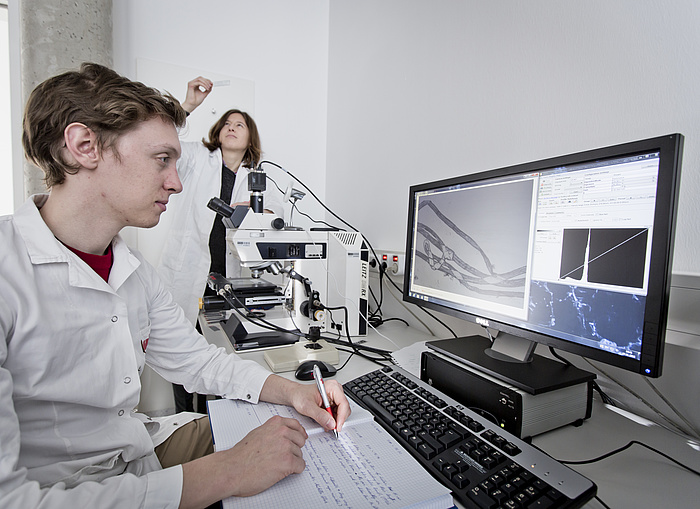

Characterising fibres

Simulations play a central role in the development of ink-jet suitable paper. Mechanical models have to be worked out for which many single paper fibres have to be characterised in the first place. “The characteristics of the paper depend on the characteristics of the individual fibers,“ explains Ulrich Hirn. “The paper depends on the raw material and how the fibers are treated.“ The individual fibres are also responsible for the printing characteristics. If they’re stiff, for instance, a bulky sheet is obtained. However at the same time, the bending stiffness is increased at the expense of the tensile strength, and absorption of liquid is improved. The Fiber swelling properties of individual fibres must be exactly investigated so that changes can be made to the paper to satisfy demands.Tedious analysis

Since each fibre has its own complex geometry and different mechanical properties, its characterisation is an extremely time-consuming matter. “To mechanically test tensile strength, elastic-plastic behaviour and creep behavior upon moisturing, we need several months to examine a single fiber grade,” reports Ulrich Hirn. A group of highly specialised experts is solely responsible for these time-consuming tests. After years of many gruelling unsuccessful attempts, maybe you can provide a detailed characterisation of several hundred paper fibres for different pulp grades.

Simulated printing presses

“It’s primarily the printing press manufacturers that need such models,” explains the paper researcher. “Because then they can simulate and optimise a new press before manufacturing it in the production shop.” To reduce the development time of printing presses, interaction between press and paper is simulated by means of simulations before production. If paper buckling occurs, the paper may rub, the paper can rub against the print head and smudge the ink. In the case of high-speed ink-jet printers, the danger of this is high since the distance between print head and paper is only around one milimetre. To avoid such problems, the printers are adapted to the characteristics of the paper in the design phase. Since the raw material paper also has strong “internal tensions”, these also have to be included in the simulations. “These tensions are responsible for many unwanted reactions, like paper curl during drying,” says Ulrich Hirn.Reinforcement for heavy duty papers

Apart from paper for printing, papers for bags, like those used in cement bags, will also be examined in depth. The research aim is to achieve an improved tear strength in these heavy duty papers while at the same time lowering costs. This is anything but an easy combination of tasks – but you never find them in any other interesting research projects.

Kontakt

Assoc.Prof. Dipl.-Ing. Dr.techn.

Institute of Paper, Pulp und Fibre Technology

Inffeldgasse 23 (A)

8010 Graz, Austria

Phone: +43 316 873 30753

Fax: +43 316 873 30752

<link int-link-mail window for sending>ulrich.hirn@tugraz.at