Can factories grow like sunflowers?

![[Translate to Englisch:] Daniel Tinello steht vor einem Paketförderband und hält eine gelbe Post-Box in den Händen.](https://www.tugraz.at/fileadmin/_processed_/6/c/csm_tinello_logist_baustaedter_tugraz_5b1e57786c.jpg)

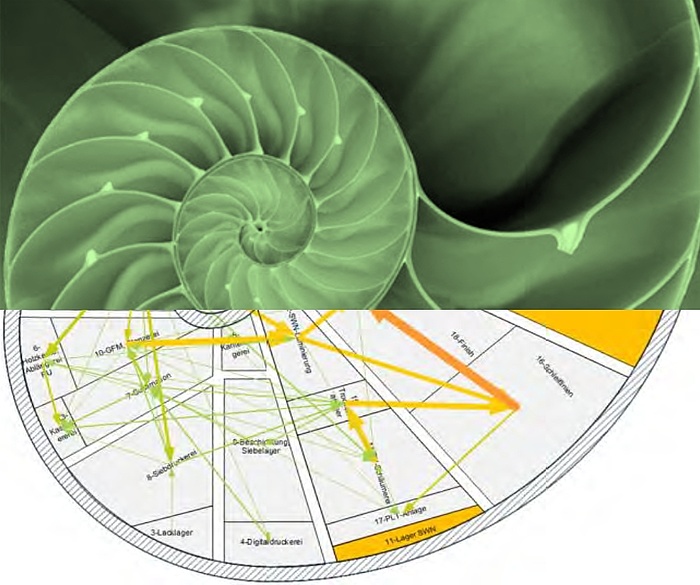

Spider web model

Spider web models have also been made use of by Daniel Tinello, project leader of the BioFacLay project, which was launched at the beginning of March and is funded by the Austrian Research Promotion Agency (FFG). Examples from nature should help in planning factories as efficiently as possible and designing internal transport routes as economically as possible. “If animals and plants grow like that, then why not a factory?” he asks. If you investigate growth processes in nature, then you regularly come up with numbers from the Fibonacci series. The eponymous Italian mathematician described the growth of a population of rabbits in the 13th century using his series of natural numbers. This principle is also, for example, found in the fruit of a pineapple, in the arrangement of sunflower seeds and in the spiral shape of the nautilus shell. This kind of growth makes optimum use of available space and light conditions. “And it looks good, too,” adds Tinello with a smile. “We’re taking the Fibonacci series as a design template for the layouts of our factories.”

BioFacLay

What was not calculated into these experiments was the cost of the necessary alterations to the factory, should a bionic layout be chosen. This is meant to be rectified in the BioFacLay project. The work will be carried out in an international team consisting of researchers from TU Graz, Vienna University of Technology, the University of Tübingen and the Brandenburg University of Technology at Cottbus. “First, the biologists in our team will look for suitable models from nature, then we’ll check them in Graz using simulations with real data from our industrial partner KNAPP AG. During this time the variants will be compared with relevant parameters and the potential assessed,” explains Tinello. By the end of the project in 2018, the idea is to present a set of useful bionic system-design patterns which can be made available for further research.

Kontakt

Mag.rer.soc.oec. Ing.

Institute of Logistics Engineering

Kopernikusgasse 24/I

8010 Graz, Austria

Phone: +43 316 873 7327

<link int-link-mail window for sending>daniel.tinello@tugraz.at