Aerodynamics on the test rig

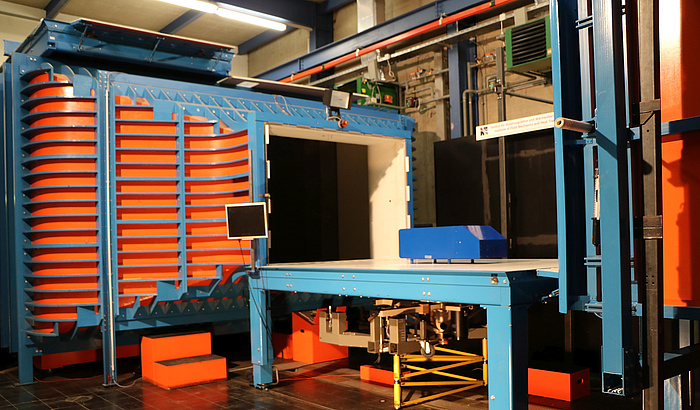

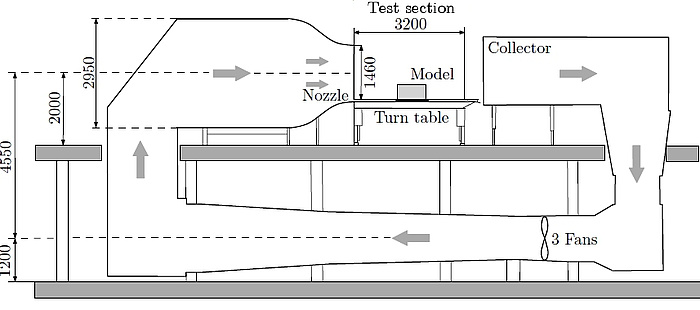

A low-speed wind tunnel powered by three fans for wind speeds of up to 145 km/h is available for aerodynamic experiments at TU Graz. The special design ensures a steady and spatially very uniform stream in the test section.

Walter Meile measures how drag and lift change when the athletes take up their usual body postures and vary them slightly. Also, how the aerodynamic properties change when the materials of the sports equipment are modified. The researchers at TU Graz’s Institute of Fluid Mechanics and Heat Transfer headed by Günter Brenn can give the athletes clear feedback after wind tunnel tests so that they can immediately habituate themselves to the optimised position and posture.

Automobile aerodynamics

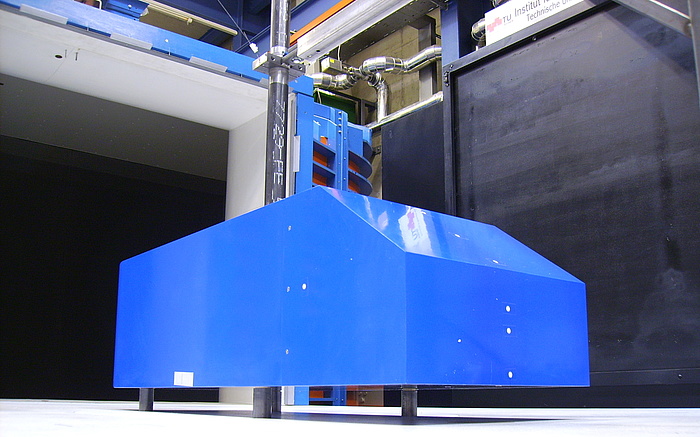

The low-speed wind tunnel is not just reserved for sports aerodynamics tests. Measurements in the wind tunnel are also important for vehicle engineering. “Aerodynamics influence many aspects of a vehicle – from design, efficiency and driving dynamics to driving stability during side winds and overtaking manoeuvres,” explains Walter Meile. To understand the underlying flow phenomena of real vehicles, the Aerodynamics Working Group at TU Graz’s Institute of Fluid Mechanics and Heat Transfer also works with generic models, such as the Ahmed body.

A recent paper of the Institute on this subject has been published in the <link http: www.sciencedirect.com science article pii s0142727x15001320 _blank int-link-external external link in new>International Journal of Heat and Fluid Flow. Further results were presented at the <link http: arc.aiaa.org doi pdf _blank int-link-external external link in new>26th AIAA Applied Aerodynamics Conference sowie der <link http: www.ara.bme.hu ocs index.php cmff cmff012 paper view _blank int-link-external external link in new>Conference on Modelling Fluid Flow (CMFF‘12). Results of sports science experiments on ski jumping were published in <link http: link.springer.com article s00348-006-0213-y _blank int-link-external external link in new>Experiments in Fluids.

Building aerodynamics

The second wind tunnel at TU Graz’s Institute of Fluid Mechanics and Heat Transfer – the so-called boundary-layer wind tunnel – was especially developed for building aerodynamics to optimally reproduce the wind profile in the atmospheric boundary layer. Here, Walter Meile and his group investigate models of buildings, such as high-rise blocks. “Our aim is to assess whether the building is fit for high wind speeds in its original size”, elucidates Walter Meile. In order to simulate the wind flow properly, the whole surrounding area has to be modelled. Using a turntable, the model can be exposed to wind from various directions.

Results of a research project on the subject of natural ventilation of residential buildings were published in the journal <link http: www.sciencedirect.com science article pii s037877881400557x _blank int-link-external external link in new>Energy and Buildings

Kontakt

Phone: +43 316 873 7343

<link int-link-mail window for sending>walter.meile@tugraz.at

Günter BRENN, Univ.-Prof. Dr.-Ing. habil.

Phone: +43 316 873 7340

<link int-link-mail window for sending>guenter.brenn@tugraz.at

Institute of Fluid Mechanics and Heat Transfer

Inffeldgasse 25/F

8010 Graz, Austria

<link http: www.isw.tugraz.at _blank int-link-external external link in new>www.isw.tugraz.at