|

DSI AT-Pile System Tests to assess the performance of the DSI pipe pile system with new connection technology |

|

Pull-Out-Tests Hollow Rod The bonding behaviour between threaded hollow rods and synthetic resin will be investigated experimentally. The motivation for the investigation is the development of a corrosion protection system with synthetic resin. |

|

MMK wood-concrete composite panels |

|

SUScrete Characterisation of a polymer mortar Polymer as a substitute binder for cement |

|

DSI Pipe Pile System Tests to assess the load bearing behaviour of the DSI AT pipe pile system |

|

ALL- in Concrete Experimental analyses on the influence of the mixed paper sack paper bag on the fresh and hardened concrete properties |

|

DSI Pipe Pile System Cement-mortar recipe development |

|

DSI Pipe Pile System Tests for the approval of the DSI AT pipe pile system |

|

DSI Pipe Pile System Test report on 4 uniaxial compression tests as preliminary tests for the approval of the DSI Hollow Bar System |

|

Fibre-reinforced concrete - Precast staircase |

|

LSW piles in the pile-driving pipe The aim of the tests is to investigate experimentally the load-bearing behavior of a noise barrier stand (LSW) in a pile-driving tube under swell load. |

|

SAS Load Transfer SAS 550/620 The load transfer test on the supporting structure of a soil nail SAS system is carried out on behalf of Stahlwerk Annahütte (SAH) according to the specifications of ETAG 013 [1] and EAD [2]. |

|

SAS Load Transfer Micropile SAS 670/800 The subject of the experimental tests is the safe load transfer into micropiles with the aid of a split tension collar in the form of a steel pipe. |

|

SAS load transfer SAS 670/800 and 835/1035 The load transfer test on the supporting structure of a soil nail SAS system is carried out on behalf of Stahlwerk Annahütte (SAH) according to the specifications of ETAG 013 [1] and EAD [2]. |

|

Stadtstraße Aspern: UHPC tunnel base with synthetic fibres On behalf of the City of Vienna, MA 29 Brückenbau und Grundbau, investigations on the use of plastic fibres in this element shall be made in addition to the concept of a white tunnel base element made of UHPC elaborated in the research report F-10-77-2019 of TU-Graz. Translated with www.DeepL.com/Translator (free version) |

|

Printbetondecke Nördlingen In the course of the project "Printed Concrete Floor Nördlingen", a section of a floor was tested for serviceability and load-bearing capacity. |

|

DSI Pipe Pile System The aim of the study is to determine the load-bearing behaviour of tubular piles under compressive loading. |

|

AVI Shear Force Thermal Basket The product range of AVI is to be extended by a thermobasket which is especially suitable for the transfer of high shear forces. |

|

TIBA crest pressure tests The aim of the investigation was to prove the sufficient stability of heavy-duty pipes with a crest pressure test. |

|

SANOOX mounting box The aim of the investigation is an experimental load capacity verification of three different mounting elements of the company SANOOX GmbH. |

|

Comparison of the approaches for fibre orientation Comparison of measurement results with the two approaches for fibre orientation distribution |

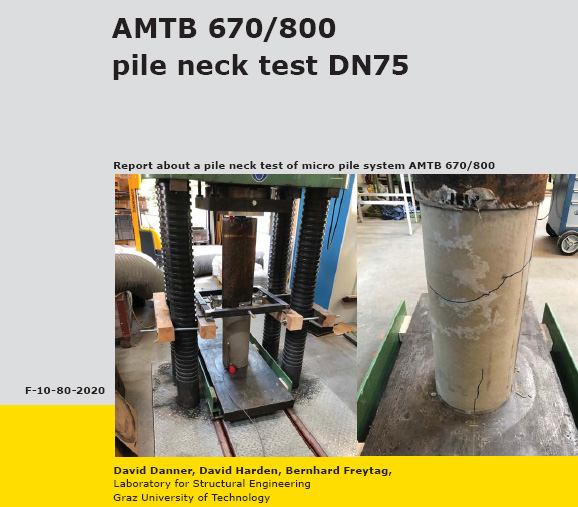

| AMTB 670/800 pile neck test DN75 Report about a pile neck test of micro pile system AMTB 670/800 |

| Normprüfung Hohldielen JHD 320 Test report on component tests on prestressed concrete hollow planks according to EN 1168 Annex J. |

| AMTB 550/620 Druckstoß mit Kontaktmuffe Expert opinion on the pressure surge with a contact sleeve type AMTB 550/620 |

| Sanierungsprojekt BV Aspern |

| IMS Montagebox Load tests on washbasin consoles Tests to determine the load-bearing capacity and permanent deformations of washbasin consoles according to EN 14688:2015-10 |

| Durchstanzversuche Tests to check the increase of the punching shear strength of the AVI-DE 140 with additionally inserted double-headed dowels on concrete slabs with the AVI-DE 140 and additionally inserted double-headed dowels |

| AVI Thermokorb 8cm Assessment of the load-bearing capacity with modified profile geometry Expert assessment of the load-bearing capacity of AVI thermocouple baskets with |

| Drehmoment-Spannkraft-Verhältnis von ISTOR-Stangen Series of tests to determine the torque-tension force ratio of ISTOR rods, and comparison with M30 threaded rods |

| Klett TGA FFG exploratory project no. 861664 Trials for the development of Velcro fastening systems for the |

| AMTB 670/800

|

| Fugenband-Prüfungen im Zuge des Projektes „Koralmbahn“ Tests of the joint tape type FMS 350 in the course of the Koralm Railway Project |

| AMTB 670/800

|

| AMTB 670/800

|

| Normprüfung Hohldielen

|

| AMTB Pull Out

|

| Auenbachbrücke Test report Test report on large-scale test on behalf of ÖBB in the course of the project |

© TU Graz/LKI | Folgemessungen B 39b Gschnitztalbrücke |

© TU Graz/LKI | Durchstanzversuche Punching tests on concrete slabs on behalf of AVI On behalf of AVI, various reinforcement systems are tested for punching failure. A total of seven eight-cornered concrete slabs measuring 300 x 300 cm are used as test specimens. |

© TU Graz/LKI | Erweiterung der Zulassung des AVI‑NIRO Thermokorb auf 12 cm Dämmstärke |

© TU Graz/LKI | Ermüdung Praterbrücke Dynamic tests on large-scale test specimens faithfully reproduced in detail The Graz University of Technology, Institute of Steel Construction, was commissioned to assess the remaining service life and thus the fatigue resistance of the steel deck of the Prater Bridge (A23 object B0214/2). |

© TU Graz/LKI | Druckkriechen Glaskleber Test report on the creep behaviour of a glass adhesive with the designation "KlarKarl" under compressive load. The object of the investigation is the creep behaviour of a glass adhesive with the designation "KlarKarl". The creep deformation of an adhesive sample under constant load is determined. |

© TU Graz/LKI | Schwimminsel Neue Donau Test report on tensile and bending tests on textile-reinforced concrete specimens The swimming island project originally came from a student competition called the "Concrete |

© TU Graz/LKI | Spannbetonschwelle L2 Strain measurements during production at the Sollenau plant MABA Track Solution GmbH produces prestressed concrete sleepers for railway construction in prestressed beds of around 100 m in length. The prestressing force must ensure that no cracks occur under specified loads. For this reason, a reliable statement about the prestressing force actually present in the finished sleeper is essential for production quality assurance. |

© TU Graz/LKI | Regalsystem BERT Tests on suspension connections The BERT shelving system is a shelving system for stepped beam and shelf racking systems, consisting of uprights and various beams or ledgers. The individual components consist of cold-formed steel profiles. The connection between the uprights and the horizontal components is made by means of suspension connections. As part of the approval procedure by the German Institute for Building Technology (DIBt), tests on the suspension connections are necessary. Tests with four different types of beams / transoms are necessary, whereby both bending and shear loads are applied. |

© TU Graz/LKI | FibreScan Non-destructive determination of the direction-dependent tensile load-bearing properties of steel-fibre-reinforced structural elements made of UHPC The lack of practicable, economical and qualitative concepts and methods of quality assurance during the construction of structures made of steel fibre reinforced ultra-high performance concrete (UHPC) strongly slows down the progress of this sustainable construction method. During the construction of the first large arch bridge in Austria (WILD bridge), a primitive non-destructive measurement method was developed and applied to determine the fibre orientation. The evaluation was accomplished by calibration on destructively examined additional samples obtained from overlengths of the components. In order to be able to dispense with this very expensive component-specific calibration process in the future, the necessary physical principles were researched in the FibreScan project. |

© TU Graz/LKI | Unterwassermontage von Feasibility study for the construction of the Central Reservoir Canal Graz by means of underwater installation of precast concrete elements. The City of Graz, represented by Holding Graz Services, is planning a central reservoir channel (ZSK) as part of the Mur power plant Graz project. This is to be constructed directly riverbed of the Mur. The construction method is a conventional in-situ concrete construction method in an excavation pit secured by stiffened sheet pile boxes and and drained by open dewatering. The expenses for securing the excavation pit and the dewatering measures are considerable, which is why the company "Der Wasserwirt" is considering an alternative new construction method with prefabricated elements that are installed underwater.

|

© TU Graz/LKI | Festigkeitsprüfungen von Klettverschlussverbindungen Experiments to determine the adhesive strength of hook-and-loop fasteners. The aim is to determine the adhesive strengths of a hook and loop fastener connection under various stresses. These were tactile tests on the Velcro strips for an application in a flexible wall system. The application is to attach panels as surfaces of a wall system to a substructure by means of a hook-and-loop fastener. The Velcro connection is intended to allow repeated use after disassembly. Accordingly, repeated use is also the subject of the investigations. In general, no reference values are known for the achievable adhesive strengths. Velcro® tapes from the Tesa Velcro® brand were tested. The majority of the tests were carried out on normal-strength Velcro® tapes. In addition, an extra-strong Velcro® tape was tested to a lesser extent. |

© TU Graz/LKI | DYWI® Drill Hohlstab-System Fatigue tests on hollow bars, coupling-anchoring and load transfer tests Execution of fatigue tests on hollow bars type R51-800 according to the requirements for reinforcing steel according to EN 10080 in the extended test scope with 3 batches and 5 specimens each. |

© TU Graz/LKI | Dehnungsmessungen Praterbrücke Metrological investigations on the A23 Prater bridge - object B0214/2 current carrying structure Subject of the investigation is the Prater bridge of the A23 in Vienna - object B0214/2 (current carrying structure). It is a steel bridge consisting of one box girder (2 main girders) per direction. The roadway deck rests on cantilevered cross ribs on both sides. The road surface lies directly on the steel deck. The measurements in question relate to the Graz carriageway, near the south end of the Strombrücke (Handelskai). In this area, there is already a widening of the cantilevered part of the carriageway deck due to the motorway exit there (about 70 cm wider than the standard area). The aim of the investigations is to measure the state of expansion of the steel roadway and of the reinforcing plates installed in this area. The results should provide information about the real conditions and be used to check FE calculations. |

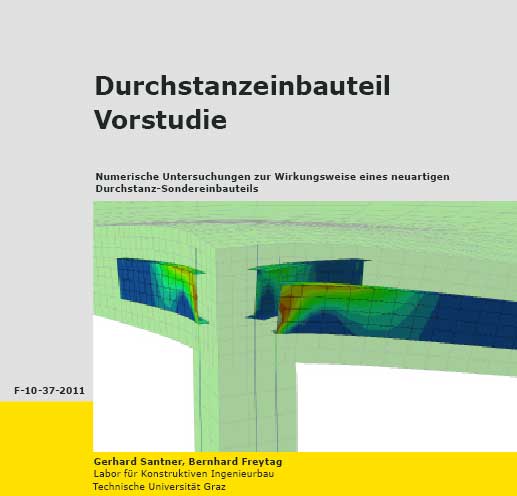

© TU Graz/LKI | Durchstanzeinbauteil Vorstudie Numerical investigations on the mode of action of a new type of special punching shear component The investigations in question concern a newly designed steel installation part for increasing the punching shear resistance of reinforced concrete flat slabs. The mechanical interrelationships of the built-in parts are to be analysed to such an extent that a targeted investigation programme based on experiments can be drawn up. The aim of this investigation programme is to subsequently introduce the new installation part to the market. The investigations in this preliminary study are largely based on numerical simulations. |

© TU Graz/LKI | HV-Verschraubung im Verbundbau Experiments to determine the bolt prestressing force as a function of the tightening torque On behalf of ASFINAG, experimental investigations were carried out at the Graz University of Technology in the Laboratory for Structural Engineering (LKI) to determine the actual prestressing force in a bolted connection as a function of the tightening torque. In the course of the retrofitting of the bridge object L43 (Tauern motorway), steel struts are connected to the reinforced concrete cantilever slab of the existing structure via a head plate and HV bolting. For the connection, a steel counter plate is arranged on the upper side of the cantilever slab. The space required for the bolts (threaded rods) to pass through (produced by core drilling) must be backfilled after installation. This backfilling concrete or mortar, the nature of its bond to the threaded rod and, above all, the age of the concrete at the time the bolting is tightened, influence the actual prestressing force of the connection. Control element present. |

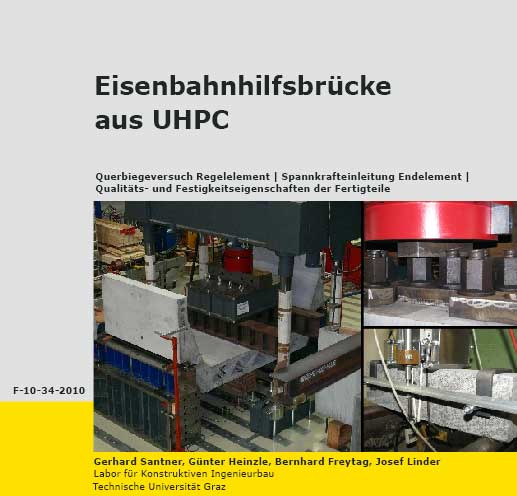

© TU Graz/LKI | Eisenbahnhilfsbrücke aus UHPC Component tests | Transverse bending test Control element | Tension force introduction End element | Quality and strength properties of the precast elements The auxiliary bridge in question, made of steel-fibre-reinforced UHPC, is a segmental bridge with a span of up to 27 m, the trough-shaped segments of which are tensioned together with up to 45 ø40 mm tension rods. The bridge is composed of control segments and one solid end element at each end of the bridge. The base plate of the regulating elements is broken up like a lattice and transversely prestressed in the upper and lower chord. Only the necessary recesses (ø60 mm) for the tension rods are provided in the end element. |

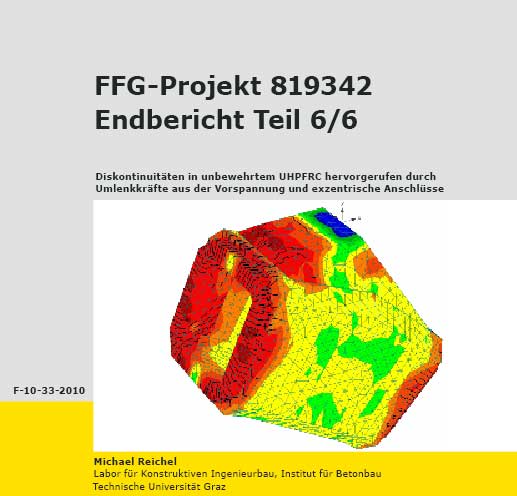

© TU Graz/LKI | FFG-Projekt 819342 Discontinuities in unreinforced UHPFRC caused by deflection forces from prestressing and eccentric connections. For discontinuity regions due to local stresses from tendon anchors, tendon deflections, lifting anchors, bearings, structural joints and due to thickness jumps and other geometrically complex shapes, design in concrete construction is usually done using truss models. In the absence of discrete reinforcing bars to carry the tension strut forces, the fibres must carry them. However, the assignment of a contributing tension zone turns out to be very complex. Since such generally valid engineering models are currently lacking, further cost-intensive and time-consuming component tests can be avoided or at least reduced by means of elaborate materially non-linear FEM analyses, which must first be verified on simple and clear component tests. Non-linear FEM analyses are also a great support for predicting and simulating the load-bearing behaviour of components with combined reinforcement made of steel fibres and reinforcing steel. Within the scope of the pilot project of the Wildbrücke Völkermarkt and other pilot projects for UHFB bridges, such analyses are used to a large extent. Non-linear FEM analyses are also to be used for the subsequent consideration of various details such as deflection forces. |

© TU Graz/LKI | FFG-Projekt 819342 |

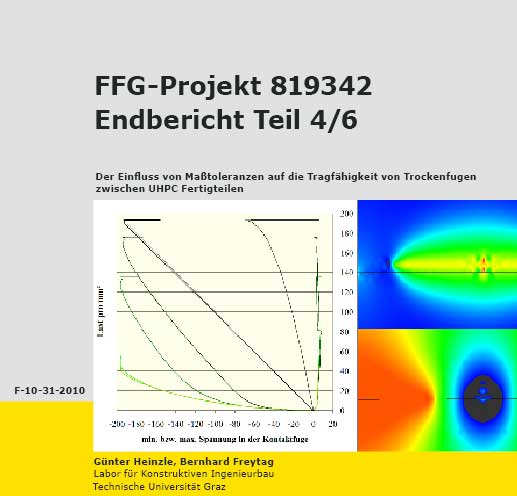

© TU Graz/LKI | FFG-Projekt 819342 The influence of dimensional tolerances on the load-bearing capacity of dry joints between UHPC precast elements. The influence of unevenness of surfaces in dry joints on their load-bearing capacity is to be investigated. Not only the size of the amplitude, but also the frequency and the shape of the unevenness will be taken into account. For this purpose, FE calculations of contact surfaces will be made in which the above parameters will be varied. |

© TU Graz/LKI |

FFG-Projekt 819342 1:1 tests to verify the load-bearing behaviour of the WILD bridge. The development of material-appropriate, cost-effective and fast construction methods in combination with material-saving lightweight cross-sections made of UHPC has already progressed so far that the first road bridge made of UHPC will be built in Austria this year. This is the so-called WILD bridge, which crosses a valley incision whose shape is very well suited for the construction of an arch bridge. The total length of the bridge is 157m, the arch spans about 70m. Due to its low dead weight, the support line approaches a polygon shape. Therefore, the arch is composed of thin-walled straight UHPC pipes and so-called "knee nodes". On top of the knee nodes, which are also made of UHPC, stands the elevation, which supports a conventional deck. Apart from steel fibres, the arches do not contain any slack reinforcement. Centric prestressing is used to overpressure the segmental joints, which increases the bending stiffness and thus improves the stability of the arch. |

© TU Graz/LKI | FFG-Projekt 819342 Manufacturing methods, fibre orientation/distribution and arch assembly of the WILD bridge |

© TU Graz/LKI |

FFG-Projekt 819342 |

© TU Graz/LKI | Wärmespeicher mit Vakuumdämpfung A buffer storage tank with vacuum insulation was developed and patented by Waukmann Energy GmbH. The outer shell is currently designed as a two-shell construction in which normal concrete takes on the load-bearing function and plastic ensures gas tightness. Due to its high impermeability, UHPC could take over both the load-bearing and the sealing function of the outer shell. It should be checked whether UHPC fulfils the required gas tightness and a comparison should be made with the plastics used. Furthermore, the danger of spalling in a vacuum is to be investigated and a pre-dimensioning for a container is to be carried out. |

© TU Graz/LKI | Zerstörungsfreie Qualitätskontrolle - WILD-Brücke Test report on inductance measurements on UHPDFRC prefabricated parts and the post-cracking tensile strengths derived from them. It is to be determined non-destructively whether the required bending tensile strengths can be expected in the longitudinal and circumferential directions. For this purpose, 3 bending tensile specimens with the dimensions 600x155x60 mm are cut out of the pipes 2 (at the edge) and 3 (in the middle) per side (top, bottom and right (viewed from behind) in circumferential direction, left in axial direction) and subjected to a bending tensile test according to DBV Merkblatt for steel fibre concrete. These tests are carried out by MFPA Leipzig. Furthermore, the ferromagnetic properties are measured at the prisms and at 120 points per pipe. By calibrating the measurements on the strengths of the sawn-out prisms, the strength of the pipes is to be inferred. The theoretical and experimental principles are documented in [1]. |

© TU Graz/LKI | ARCO R90 Termic in Tension Tensile tests on a drill pipe with a diameter of 90mm The subject of the investigations is the determination of the maximum tensile force of a drill pipe of the company Keller Grundbau with the designation "R 90x8 Termic" and a diameter of 90mm. The set-up for the tensile test consists of three drill pipes of the same type with a total length of 7000mm (see Figure 1). Two of the three drill pipes have a length of 3000m, the third is 1000mm long. The three individual pipes are bolted together with two matching 230mm long couplings. The coupling points can also be seen in Figure1. The connection points to the test equipment are realised with two halved sleeves. One at the top of the cylinder, the other under the load cell in the basement. |

© TU Graz/LKI | Dehnungsmessungen L43 Steinbrückenbachbrücke Metrological investigations at the L43 Steinbrückenbach bridge of the A10 Tauern motorway The object of the investigations is the object L43 of the A10 Tauern motorway. It is a composite bridge with a total length of 606m, which extends over 9 spans. The bridge consists of one supporting structure per directional carriageway. The investigations in question relate to bars, designed as round steel tubes, which support the cantilevered carriageway slab towards the main girder D (directional carriageway Villach). The objective of the investigations is to record real strains in the console bars. Subsequently, the actual stress on the bars is to be determined from these strains, which in turn are to form the basis for a service life calculation. For this purpose, the strains of the bracket bars are measured in the area of pier 3 from three brackets at different distances from the pier. |

© TU Graz/LKI | FFG -Projekt 813129/621 Crack width development of UHPC slabs subjected to bending loads - theory and test |

© TU Graz/LKI | FFG -Projekt 813129/621 Dimensioning and testing according to ÖNorm EN124 of UHPC manhole covers of load classes A50 and B125 |

© TU Graz/LKI | FFG -Projekt 813129/621 Design of watertight circular tanks made of UHPC |

© TU Graz/LKI | FFG -Projekt 813129/621 Shear measurements of thin-walled cross-sections made of UHPC Test - FE calculation |

© TU Graz/LKI | FFG -Projekt 813129/621 Determination of fibre content and orientation by photographic method - theory and application |

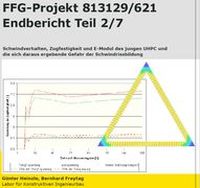

© TU Graz/LKI | FFG -Projekt 813129/621 Shrinkage behaviour, tensile strength and modulus of elasticity of young UHPC and the resulting risk of shrinkage cracking |

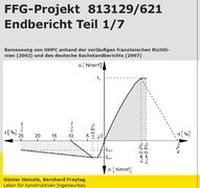

© TU Graz/LKI | FFG -Projekt 813129/621 Design of UHPC based on the French preliminary guidelines (2002) and the German expert report (2007) |

© TU Graz/LKI | Alu Profil- Verbindungen Carrying out tests to verify the load-bearing behaviour of aluminium profile connections |

[Translate to Englisch:]

© TU Graz/LKI | UHPC Brücke Amlacherstraße Carrying out tests to verify the load-bearing behaviour under transverse bending loads |

© TU Graz/LKI | Wandpfeiler unter zentrischem Druck Carrying out tests on storey-high, polyurethane-bonded masonry pillars |

© TU Graz/LKI | MAI Hohlstabanker gekontert Carrying out static system tests on countered MAI hollow bar anchors with socket connection |

© TU Graz/LKI | Dehnungsmessung L40 Metrological investigation on vertical buckling stiffeners and gusset plates of the object L40 of the A10 Tauern motorway |

© TU Graz/LKI | Bewehrungssuche Haus Hölzl Reinforcement search on the balcony slab Haus Hölzl |

© TU Graz/LKI | Bremsbeläge ROLA TS Shear tests on brake pads |

© TU Graz/LKI | Messungen B39b Gschnitztalbrücke Measurement investigation at the B39b Gschnitztal bridge of the A13 Brenner motorway |

© TU Graz/LKI | Dehnungsmessungen L40 Measurement investigation on vertical buckling stiffeners of the object L40 of the A10 Tauern motorway |

© TU Graz/LKI | Schwingungsmessungen ORS Kolomannsberg Measurement investigation of the vibration and deformation behaviour at object H of the ORS Kolomannsberg. |

© TU Graz/LKI | Tragverhalten nachträglich ergänzter Fahrbahnplatten Road research project 3.287 of the Federal Ministry of Transport, Innovation and Technology |

© TU Graz/LKI | Semperit Schwellenschuh Experimental determination of the static and dynamic stiffness as well as the mechanical fatigue strength |

© TU Graz/LKI | DYWIDAG Post-Tensioning Kit Approval tests for the 4-strand tendon with and without coupler type M |

Laboratory for Structural Engineering

Inffeldgasse 24

8010 Graz

Tel.: +43 (0) 316 / 873 - 7051

Fax: +43 (0) 316 / 873 7061

lkinoSpam@tugraz.at