|

© TU Graz/LKI

|

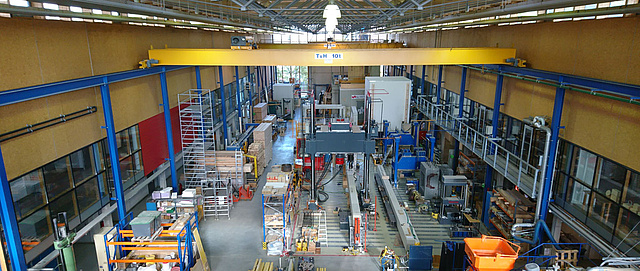

The tensioning field (10 x 20 m)

- Two-row "prestressed concrete box girder" separately founded and with a 1.0m thick tensioning slab (two-axis and two-layer prestressed)

- Steel tensioning rails at 0.5m intervals Tensioning grid: 50x50(100)cm Anchor force per anchorage: max. 500kN

- Underfloor hydraulic ring line with taps

|

© TU Graz/LKI |

1MN testingmachine (2 pieces)

4 column test scaffold (column distance: 1 x 2,5m)

- vertically adjustable transverse yoke with hydr. mech. clamping (clear height max. 2.7m)

- longitudinally adjustable at the clamping field and coupled with the clamping field (hydr. pre-tensioned tie rods)

- can be equipped with test cylinders (100kN and 1000kN)

|

© TU Graz/LKI |

3MN or 4MN testingmachine (1 piece)

4-column test scaffold (distance between columns: 1.5 x 3.5m)

- vertically adjustable transverse yoke with passive clamping (clear height max. 5.0m)

- longitudinally adjustable (l= ±3,5m) and coupled to the clamping field (hydr. pre-tensioned tie rods)

- can be equipped with 1MN and 4MN test cylinders

|

© TU Graz/LKI |

Reaction wall elements

modular reaction wall system

- clamped to the clamping field

- Modules in different sizes

|

© TU Graz/LKI |

100kN test drive (1 piece)

Servo-hydraulic test cylinder MTS F= ±100kN, hmax= 250mm

- with foot plate or head and foot joint and spherical pressure plate

- Load cell and deltap transducer

|

© TU Graz/LKI |

1MN test drive (2 pieces)

Servo-hydraulic test cylinder MTS F= ±1000kN, hmax= 250mm

- with foot plate or foot and head joints (the latter "backlash-free") as well as spherical pressure plate

- load cell and deltap transducer

|

© TU Graz/LKI |

4MN test drive (1 piece)

Servo-hydraulic hollow piston test cylinder

Fstat= ±4MN, Fdyn= ±3MN, hmax= 250mm, di= 250mm

- spherical pressure plate (pendulum axis)

- load cell and deltap transducer

- Bending moment measurement X/Y

|

© TU Graz/LKI |

Universal testing machine BETA1000

Fmax=1000kN, Compression hmax=1200mm, Tensile hmax=900mm

- Crosshead speed: 0 to 200mm/min

- High-precision electromechanical test frame with high lateral as well as axial stiffness

- The lower test area is designed for tension/compression and alternating load tests up to the capacity limit

- Main drive with low-inertia servo motor and digital position feedback

- Constant speed of the moving crosshead, acting via a precise recirculating ball screw

|

© TU Graz/LKI |

Hydraulic wedge clamping system

Fmaxstat=333kN, Fmaxdyn=250kN

- Hydraulic tensioning system for tensile tests

- for MTS 100kN, MTS 1MN and BETA1000

- Connection thread: M36 x 2

- Clamping jaws for round and flat specimens

- specimen thicknesses:

Round specimens: d=5mm to d=30mm

Flat specimens: 1mm to 40mm

|

© TU Graz/LKI |

Universal testing machine Shimadzu AG-50

Fmax=50kN, hmax=1000mm

- crosshead speed: 0 to 1000mm/min

- Tensile/compression and alternating load tests

|

© TU Graz/LKI |

Compression testing machine

Fmax= 5000kN, hmax= 80mm, maximum installation height: 380mm

- spherical pressure plate

- modular intermediate plates

|

© TU Graz/LKI |

Torsion test rig

Mmax= 5000Nm

- variable specimen mounting

- Half shells for drill core mounting

|

© TU Graz/LKI |

Tear frame

hydraulic prestressing frame

- prestressing length: 4m

- Fmax=1000kN

|

© TU Graz/LKI |

Tensile adhesion tester

Hydraulic tensile tester

- Strain Gauge applied tension spindle

- for drill core and cylinder testing

|