Workflow = Forceflow

Linking parametric design and production methods for developing, designing and constructing structural systems - dissertation subject of Dipl.-Ing. M.Sc. Felix Amtsberg.

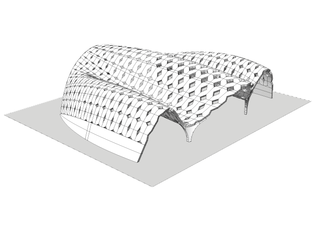

This dissertation presents new possibilities of linking the flexibility of parametric design techniques to the use of industrial robots in order to manufacture statically oriented structural systems and their segmentation in producible components.

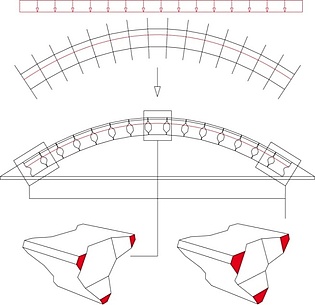

With just a few exceptions, parametric programmes are still almost exclusively used for creating designs. The question of materiality and the related question of production remains unanswered – it is outsourced and declared as a specific problem. One model is prepared for presentation and a later one for production, which naturally entails making necessary compromises and thus also differences between design and finished product. This problem increases with the complexity of the geometry. Hence, digital parametric tools can be used to create countless versatile dual curvature structural systems without any problems. In reality though, their production time proves to be new and elaborate time and again, thus losing a wealth of great and simple variants on the way to production. One of the most effective methods for geometrically determining a structural system is natural form-finding. This method of determining building geometry and structural systems has shaped entire architectural epochs such as the Romanesque or Gothic periods and brought forth countless examples of its capability.

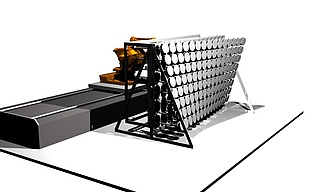

That those techniques are no longer used is owed to the fact that elaborate production methods such as mould construction and the erection of formwork always needed to be designed and constructed starting from scratch. While in the past, changed production methods have reflected concerns regarding that issue, the introduction of the industrial robot as a new architectural means is only a recent innovation. Hence, the possibility of incorporating production in the design process will play a central role in this dissertation. Application was demonstrated in specific case studies.

Central Case Study

The central case study involves developing and realising an adaptive formwork (controlled by an institute-owned industrial robot) and its use in the production of digitally generated formwork geometry. The concept involves developing the necessary tools (formwork, addressing unit, etc.) to deal with the material (concrete/UHPC), and related to that, digital form-finding, segmentation in producible elements as well as the compilation of production files which can be processed by the required machines. The ultimate goal is to realise a 1:1 prototype of a UHPC shell structure made of precast UHPC segments.