2023

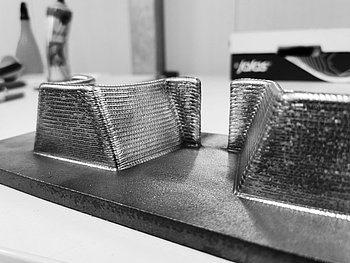

3DWelding – Additive Manufacturing of Structural Steel Elements

DI Christoph Holzinger, BSc

The FFG project “3DWelding: Additive Manufacturing of structural Steel Elements” should investigate the potential for 3D printed steel elements within the field of construction. The question is, is it possible to produce a structural element in the 1:1 scale which achieves the relevant static and dynamic requirements, as well as other requirements such as the surface quality and accuracy. Both topology optimised free-forms and regular forms should be investigated.

2016

Sensory Parametrics

Dipl.-Ing. Felix Amtsberg, MSc

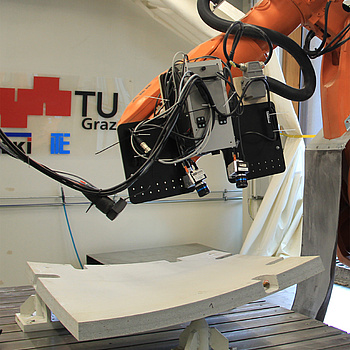

Combined with the progress in building material technology, especially in the field concrete constructions, the research field of adaptive moulding strategies has redeveloped and led to the following research question: Does the industrial robot enable the resource efficient and cost effective production of concrete shells and freeform structures if they are subdivided into elements which can be prefabricated?

The work contributes a feasible concept for the fabrication of double-curved concrete elements with a small batch size, but delivers a contribution to the discussion of feedback based process development and actuation for the manufacturing process of construction elements for architectural purposes.

TU Graz Library

2014

Thin-walled supporting structures made of carbon-concrete – Contribution to improve resource-efficiency of structural-concrete

Dipl.-Ing. Franz Forstlechner

Due to the development of high-performance concrete types with enormous mechanical strengths, high durability and reliably adjustable consistency, it is possible to fabricate structural concrete elements with a thickness of just a few centimetres today. Also, the development of corrosion-resistant and high-strength reinforcement made of carbon-fibres favours this tendency, since it allows concrete-covers within a few millimetres. Therefore, the central research-question of this doctoral thesis is how thin concrete slabs with a maximum thickness of five centimetres should be reinforced in order to attain both, a high flexural stiffness under service load, and a high bending load capacity and ductility? The method of solution followed in the context of this work is to reinforce the concrete with laid webs made of carbon-fibres, which are placed as close as possible to the surface, and to add centric tendons in the areas of greatest stresses, which are pre-stressed in tensioning-bed.

TU Graz Library