Graz reinforced concrete lightweight construction expertise for the Operationcenter in Bludenz

© ITE, TU Graz

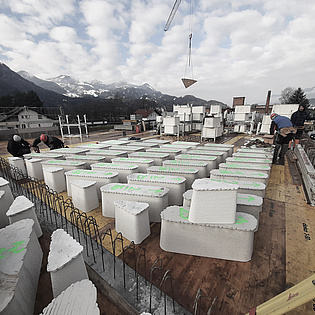

Commissioned by Tomaselli Gabriel Bau GmbH, Baumit GmbH and gbd ZT GmbH Dornbirn, the Institute of Structural Design of the Graz University of Technology was significantly involved in the design of a 717m² flat roof in reinforced concrete lightweight construction for the Werkhof in Bludenz. The team of the institute was responsible for the design of the roof structure with a free span of 14m as well as for the development of the print strategy of the 3D-printed recess bodies and thus contributed its expertise in the implementation of the novel construction method to the largest construction of this kind worldwide so far.

The construction project was completed at the beginning of 2023 and is representative of the use of 3D concrete printing as a promising option for the construction of filigree and sustainable load-bearing structures in lightweight reinforced concrete. Load-bearing structures are responsible for 50-70% of a building's CO2 emissions and therefore offer enormous savings potential for future construction measures.

Approach

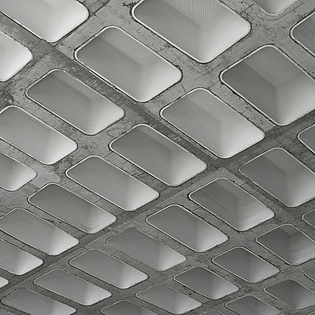

The "Graz lightweight reinforced concrete construction method" based on printed formwork was developed and extensively tested at Graz University of Technology as part of an FFG research project. In the meantime, about 1000 square meters of the lightweight reinforced concrete structures are already in use for structural elements such as ceilings and roofs. The central element here are 3D-printed formwork elements which remain in the component as permanent formwork. In this way, the concrete cubature of in-situ concrete structures can be drastically minimized and a solid slab with a rectangular full cross-section can be transformed into a cross-section-optimized coffered slab.

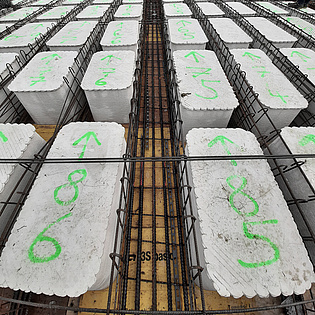

In order to be able to optimally design the geometry with regard to the prevailing tensioning direction and support situation, the team in the present project analyzed the trajectory in a first step. Based on these results and taking into account the geometric boundary conditions of the recess bodies, an equally optimized and harmonious geometry could be determined. Then, the roof structure for the work yard was pre-designed according to applicable standards (EC2 with NAD), the required concrete strength was determined and the degree of reinforcement was determined. In addition to the force distribution, the dimensions of the total of 792 3D-printed recess bodies played a particularly important role, since weight and size correlate with each other. In addition, the pallet dimensions had to be maintained and the weight selected so that it was possible for two people to manipulate the recess bodies on the construction site.

Other important factors for the dimensions of the recess bodies were above all the dimensional stability of the objects during the printing process and concreting at the construction site. Here, neither deformations nor fractures of the shuttering bodies due to excessive concreting pressure were allowed to occur.

Other important factors for the dimensions of the recess bodies were above all the dimensional stability of the objects during the printing process and concreting at the construction site. Here, neither deformations nor fractures of the shuttering bodies due to an excessively high concreting pressure were allowed to occur. Thanks to the good cooperation with the project team, the proposed geometries were quickly manufactured and checked at the 3D concrete printing company Concrete-3D GmbH.

In addition to the consulting activity in the structural analysis, guiding details in the reinforcement design were developed with special attention to the shear force bearing capacity.

Result

In the construction project, the consistent use of 3D printing technology saved close to 24% CO2eq. In addition to the concrete saved by the recess bodies, a portion of the reinforcing steel was eliminated by reducing the dead weight of the structure. In total, the original design would have resulted in 135 toCO2eq 121 to, whereas the optimized design manages with only 102 toCO2eq 70 to. Thus, 33 toCO2eq 50to could be avoided by the deck structure alone. Digital fabrication proved to be the central tool for making time-consuming formwork work more economical. The project is a further milestone in the research and application of new, more resource-efficient and low-emission construction methods for lightweight reinforced concrete structures. The latter in particular requires the integration of planning and research as well as cooperation with future-oriented companies.

Project duration:

February 2022 - March 2023

Client:

City of Bludenz

WERIT Handels GmbH Austria, Bludenz

Project team:

Atelier Ender, Nüziders

BAUMIT GmbH

Concrete 3D, Nüziders

gbd ZT GmbH, Dornbirn

Institute for structural design: Georg Hansemann, Christoph Holzinger, Robert Schmid, Andreas Trummer, Stefan Peters

City of Bludenz

Tomaselli Gabriel Construction, Nüziders

WERIT Handels GmbH Austria, Bludenz