Mobility Sensor Solutions

The institute of machine components and methods of development at Graz University of Technology sets new standards in wireless measurement of temperatures and lubrication states in drivetrain components. In the Mobility Sensor Solutions department at the institute, innovative sensor solutions for data acquisition in the powertrain are being explored and developed. The wireless measurement of temperatures in clutches, bearings and electrical machines is essential in the development process towards sustainable mobility.

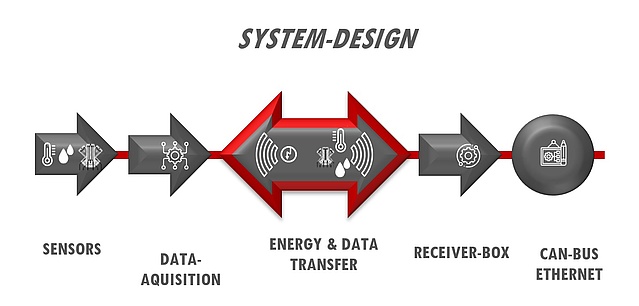

An innovative approach for contactless data acquisition on rotating systems was realized. The uniqueness of the telemetry is focused in the compact design according to individual project situations to influence the measurement object in a least invasive way. Besides, the functionality of online sensor defects detection and noise suppression offers a significant advantage over competing systems. As metric values, we are currently concentrating on mechanical strain, temperature and lubricant state measurement with the flow sensor. Special expertise was built up in the instrumentation of 0.5mm diameter mineral insolated thermocouples. This type of thermocouple is very reliable at high temperatures and vibrations, making it particularly suitable for measuring temperatures in the drive train.

Up to 32 measurement channels make the system ideal for digital twin data input or troubleshooting of powertrain components. Due to the robust and compact design, the telemetry can be used in the vehicle without major changes to the specimen. The interface from the measuring system via CAN is user-friendly to handle and compatible with the current industry standards. As a professional project partner, we offer our customers project support for planning, instrumentation, functional tests and measurement support as well as data evaluation. As a full-service supplier, we guarantee the functionality of the wireless measurements in your project.

USE-CASE: E-machine:

This customized telemetry was developed for temperature measurements of the E machine. The aim is to minimize the set-up time and the system installation at the test bench. For this reason, an interface was designed for thermocouple sensors, which is directly attached to the rotor shaft. This interface is minimally invasively integrated into the clamping ring of the resolver shaft and remains as a single use part on the rotor shaft. At the test rig, the operator attaches the telemetry ring with an outer diameter of 58 mm and a width of 6 mm to the clamping ring with four screws and the installation is finished.

.

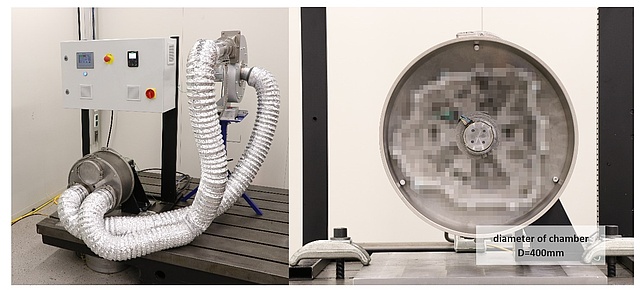

Testbed for functional tests

Special attention and differentiation are focused on the function test of the sensors systems. In a configuration like the practical configuration or with instrumented specimism components, an end of line test of each telemetry system is carried out on the functional test rig. Two test rigs are available for the end of line tests.

On the one hand side the high-speed test stand was developed especially for high-speed telemetry solutions that can be rotated up to a maximum speed of 30,000 rpm. In addition to the speed tests, the specimism can be temperature controlled from -40°C to 150°C. Furthermore, the test procedure is possible under ambient oiling of the components.

The function test on the component test bench is always the final check before delivery of the telemetry or the instrumented machine components to the customer.

THEISSL systems GmbH

Inffeldgasse 21b/II

8010 Graz

Koordinaten:

47.058334, 15.463525

Email: office@theissl-systems.com

Web: www.theissl-systems.com