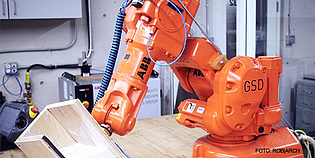

Robot Type: 3 x ABB IRB 140

Robot Controller: IRC 5, Robotware 5.14

Payload: 6 kg each

Special Equipment: Custom End Effectors, Mill

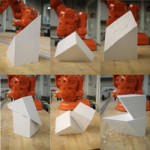

Software: ABB RobotStudio, Rhino, Grasshopper with custom components

Institution: Graduate School of Design, GSD Harvard University, Design Robotics Group