3D*3B, 3D concrete printing and reinforcement for low-emission load-bearing structures in building construction

The technology of 3D printing with mineral materials in a kind of extrusion process is the starting point for the research project. This technology currently offers the possibility of producing unreinforced components very precisely and with low material input at high speed in an automated way. For the first time in the history of concrete and reinforced concrete construction, the otherwise necessary and costly mold construction for the usual casting process is no longer required.

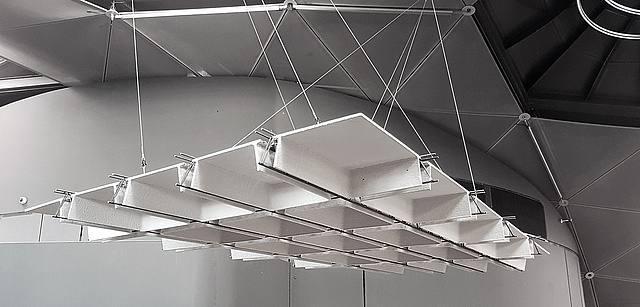

Based on the application of the printing process for the production of molded formwork components, the aim is to combine the technology with common processes in building construction in order to make greater use of potentials for reducing concrete cubage and the associated lower greenhouse gas emissions for load-bearing structures in building construction. A major limitation here is the lack of guideline-based characterization of unreinforced and reinforced compaction materials and components made from them. As a result, the technology cannot currently be integrated into common BIM-compatible planning and design processes. The use of 3D-printed components as displacement bodies in the construction process leads to increased geometric complexity, which increases the requirements for the corresponding processes on the construction site. This concern, for example, the installation, placement of 3D-printed concrete components and steel reinforcement for in-situ concrete additions.

The aim of the project is to create the basis for numerical simulations of unreinforced and reinforced 3D-printed concrete components through a systematic development of test setups and through mechanical test series. Exemplary applications for building construction are ultra-light facade panels with reinforcement integrated in the printing process and 3D-printed formwork and displacement bodies for mass reduction of flat slabs. The focus is on issues of steel reinforcement, construction logistics and climate compatibility assessment.

Expected results

After completion of the project, methods and data for the characterization of 3D-printed concrete components will be available, enabling numerical simulation in the design and planning phase. Selected application examples will be used to clarify and evaluate the potential of 3D-printed concrete components to reduce concrete cubage and associated greenhouse gas emissions in building construction. Construction processes and construction logistics, in particular the integration of 3D-printed concrete components and necessary steel reinforcement for in-situ concrete additions, will be developed and tested for BIM-compatible processes.

Projectmanagement:

Institute of Structural Design, TU Graz

Projectpartners:

Laboratory for Structural Engineering, TU Graz (Bernhard Freytag)

Institute of Production and Logistics, BOKU Vienna (Manfred Gronalt)

Baumit GmbH (Peter Weissmann)

AVI Alpenländische Veredelungs-Industrie Gesellschaft m.b.H. (Gerd Unger)