Converting Real Objects to Mathematical Models for Design and Simulation

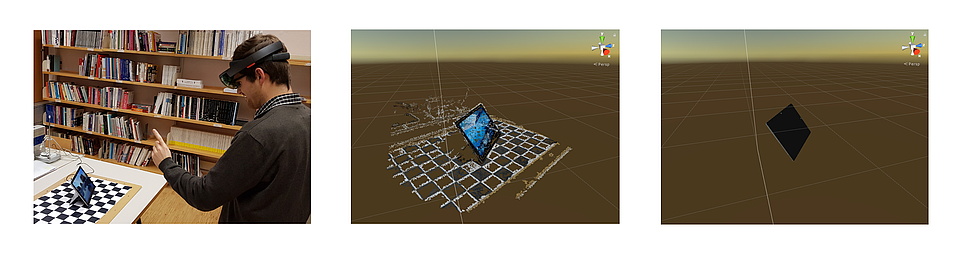

Real Objects in Virtual Reality

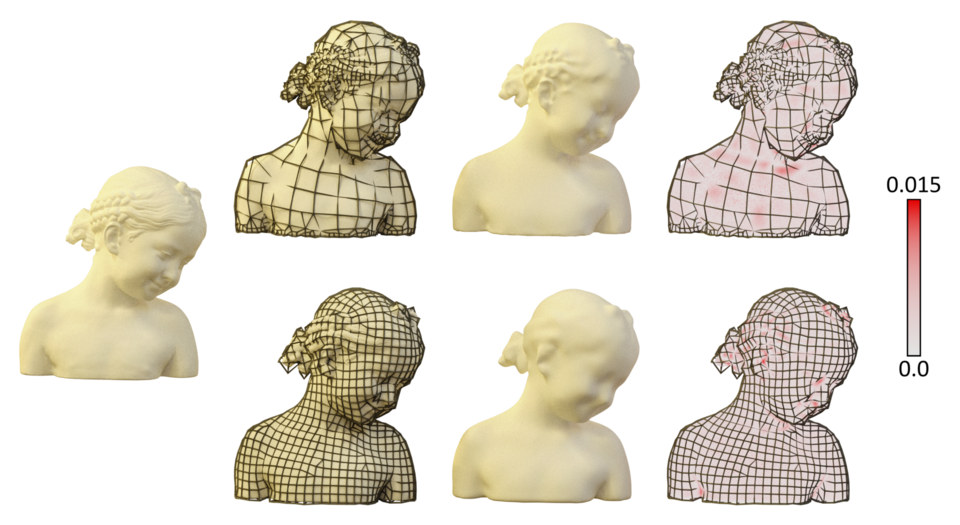

Virtual environments (VR) are used more and more to depict digitised artefacts of various kinds. Users are able to visit everything from virtual museums where scanned in versions of real artefacs are displayed, to entire buildings from the comfort of their living room. The advantage here is that not only does it not require any time consuming travel, it also enables the viewer to get very close to objects, which may otherwise not be possible and also to interact with objects where it may not be possible in the real world scenario. Thus, when we want take full advantage of VR, we should aim toward creating immersive interactive virtual worlds which not only provide plausible visuals, but also allow the user to interact with artefacts and the visual scene in a natural way. While rigid-body physics simulations are widely used to provide basic interaction, realistic soft-body deformations of virtual objects are challenging and therefore typically not offered. However, in the real world we are used to interacting with things, e.g. to assess material properties of an object upon how it responds to interaction. Therefore, having only rigid objects in VR reduces immersion since many real world objects are easily deformed. To enable users to interact with an artefact in a plausible way, so that response of the artefacts to this interaction may help to assess material properties, the response of the objects needs to simulate accurate physical behaviour which is typically determined through a detailed finite element analysis of the object.

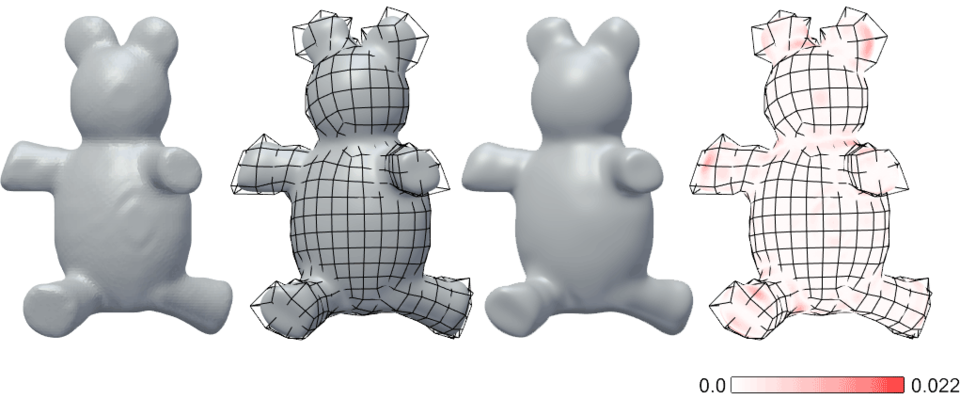

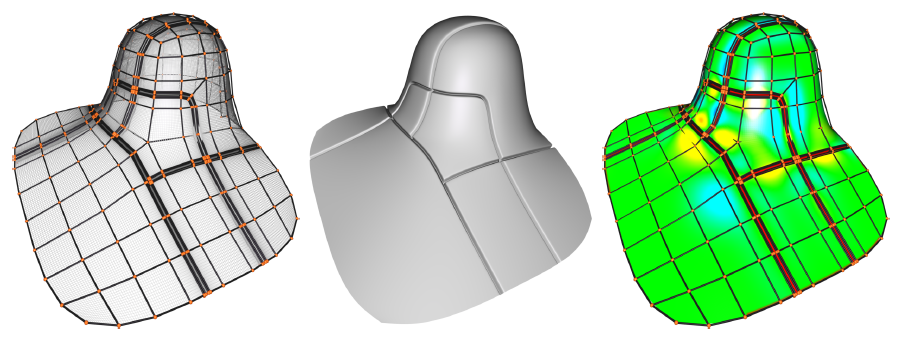

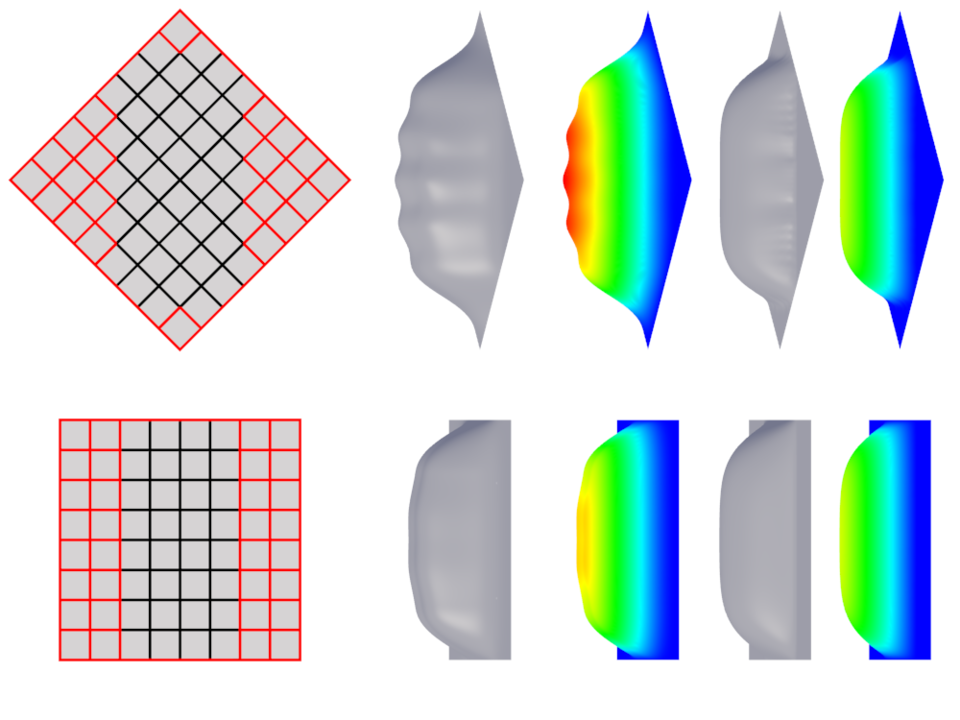

To enable realistic interaction with objects in VR environments on a range of devices with various capabilities, we propose a client-server approach which makes use of subdivision based isogeometric analysis. This requires to convert the highly detailed scan of the real object to be converted to a coarse subdivision control mesh. Deformations are computed on a central server and results are available to multiple clients. By using subdivision surfaces to represent the geometry and to perform the simulation computations, bandwidth usage is kept low and different clients can easily render different levels of detail according to their capabilities.

The project was made possible by the FWF Wissenschaftsfond, Project Nr. E-1711P24481.