Electrical Capacitance Tomography - Flow measurement for pneumatic conveying

Pneumatic conveying is among the most important industrial transport techniques for pulverized and granular material. In pneumatic conveying the particular transport good is transported by means of a gas stream in a pipeline.

Flow measurement in pneumatic conveying is a challenging task. Various sensing principles are addressed in literature, e.g. mechanical, electrical, optical and acoustic principles can be found.

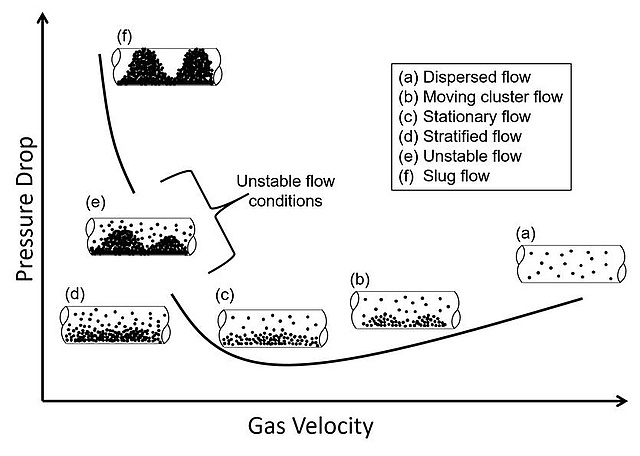

In horizontal transport pipes, also the flow regime is relevant. The flow regime refers to the spatial and temporal distribution of the granular material in the transport pipe. An overview about different flow regimes is given in Figure 1. The different flow regimes make flow metering in horizontal lines even more challenging. Knowledge about the flow regime is also relevant for the operation of pneumatic conveying systems, as the flow regime determines the energy demand of the transport system, or the abrasion of the pipe installation.

EMS has a strong research background in the application of capacitive sensing technology for flow measurement in pneumatic conveying. Capacitive sensing is a suitable technique due to its advantageous functional and constructional principles, allowing the assembly of robust and cost-efficient sensors.

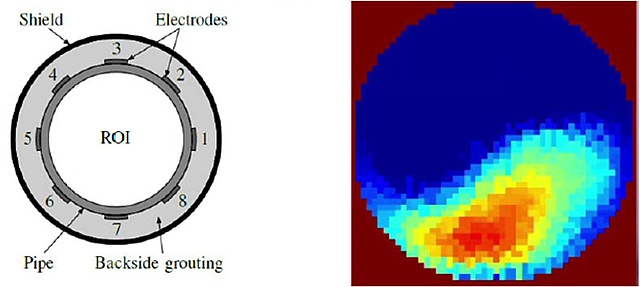

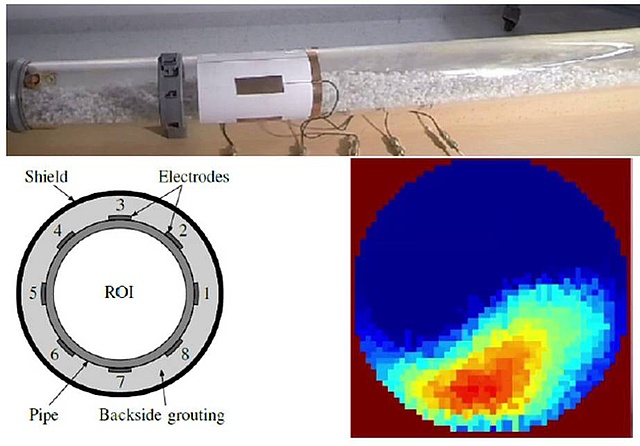

A core technology for the application of capacitive sensing for flow metering is electrical capacitance tomography (ECT). ECT is an imaging method to determine the spatial dielectric material distribution within a domain (region of interest, ROI) from capacitive measurements at the boundary. Figure 2 exemplary depicts a lab demonstrator for flow measurement. Electrodes are placed on the outside of a pipe. Based on capacitive measurements between the electrodes the material distribution can be estimated by means of suitable signal processing methods.

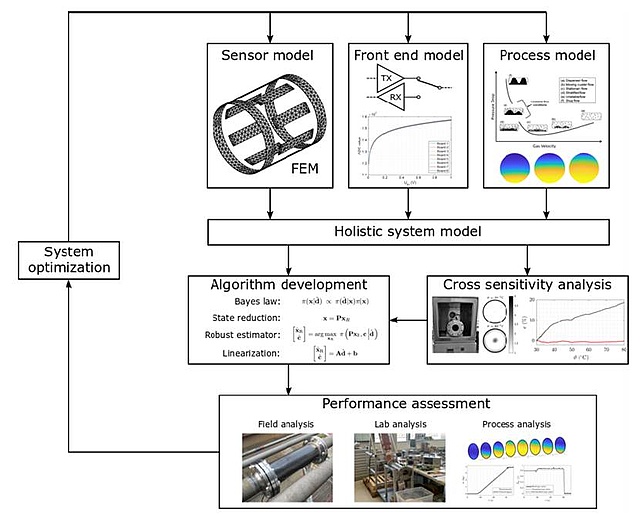

The research of EMS covers the development of sensors, measurement systems and model-based signal processing methods. The development requires a holistic approach, where all aspects of the measurement system are considered. An essential element for the development of flow metering techniques is the incorporation of prior knowledge on particulate flow processes. Hereby EMS collaborates with the CDL for Particulate Flow Modeling (JKU / Linz). In joint research projects the team could demonstrate the application of capacitive sensing technology for flow measurement in harsh industrial environments. The research in this field is continued within the CDL for Measurement Systems for Harsh Operating Conditions.