Project Description

Flywheel energy storage can be used in personal cars and commercial vehicles with a hybrid propulsion system to either recuperate braking energy or for load leveling. These measures can reduce fuel consumption by up to 20 percent in urban driving cycles. Kinetic energy storage offers a variety of advantages compared to competing technologies like batteries or supercaps. Flywheels offer extremely short charging times, a high number of cycles, no capacity fade over time, the energy content can be exactly quantified and, finally, no limited or environmentally harmful resources need to be used.

However, the results of recent research projects as well as observation of the current market have shown that the flywheel bearings are still the limiting factor of this technology. Especially the high requirements in terms of life time, ranging from several thousand hours in a personal car up to service intervals of 40.000 hour (7 years) in rail vehicles can hardly be reached by rolling element bearings in flywheels. According to the current state of the art these requirements can only be met by magnetic bearings, but their costs, their weight and space are significantly higher than in the case of rolling element bearings. This is why magnetic bearings are almost exclusively used in stationary surge power units while conventional bearings would be a much better solution for mobile applications.

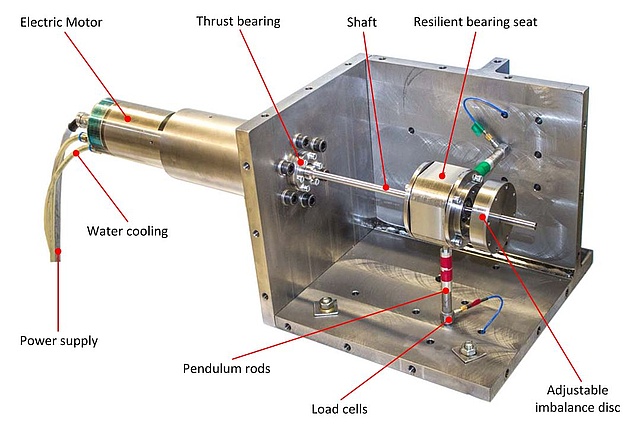

In order to reach the life time requirements, the loads on the mechanical bearings in a flywheel system would have to be reduced significantly. Since it is not possible to further reduce the mass imbalance forces of the rotor with acceptable effort, this project will investigate the possibility to at least reduce the effect of imbalance and gyroscopic forces so that rolling element bearings reach the desired life time. This should be reached by decoupling the bearing from the housing using an active and/or passive compliant mount for the outer bearing race. For active decoupling a piezo-actuator will be used making it possible to actively intervene in the system and reduce imbalance forces. One of the most important results of this project is a simulation model that represents the whole flywheel system including the bearing mount. With this tool a theoretic proof of functionality of the desired bearing mount will be possible.

Furthermore, the simulation model will provide information on the robustness of the control algorithm (i.e. if rotor imbalance increases over time) and the number and position of the sensors required for rotor monitoring. Also, the possibility to replace the desired active bearing control by a passive compliant mount will be analyzed with the help of this model. Final outcome of this project will be a hardware test bench to verify the results and knowledge acquired through the simulation model.

Project Data

Project Type: Joint Proposal

Program: FFG – Mobility of the Future, 3rd Call

Duration: 2 years

Status: Finished

Workgroup: Energy Aware Measurement Systems