Research activities

Data-driven modeling and optimization of highly cross-linked industrial plants

The globalized and highly competitive world economic system puts all branches of the process engineering industry under constant pressure to constantly improve measures to ensure optimal plant operation. State-of-the-art for the design and optimization of processes are physical-mechanistic white box models within the framework of commercial process simulators, with which single-criterion optimizations can be carried out.

New modeling and optimization approaches which are subsumed under the term ‘big data’ have partially gained a foothold in the IT area, introducing data-driven modeling techniques and multi-criteria optimization approaches of coupled black box models. However, these approaches are not yet part of commercial process simulators and are not yet used consistently in the process industry, although the availability of historical process data in the context of process databases would suggest the use of big data methods.

The aim of this work is to investigate the applicability of big data methods in the modeling and optimization of process engineering plants which go beyond the existing possibilities of commercial process simulators. This scientific discussion is intended to highlight three aspects:

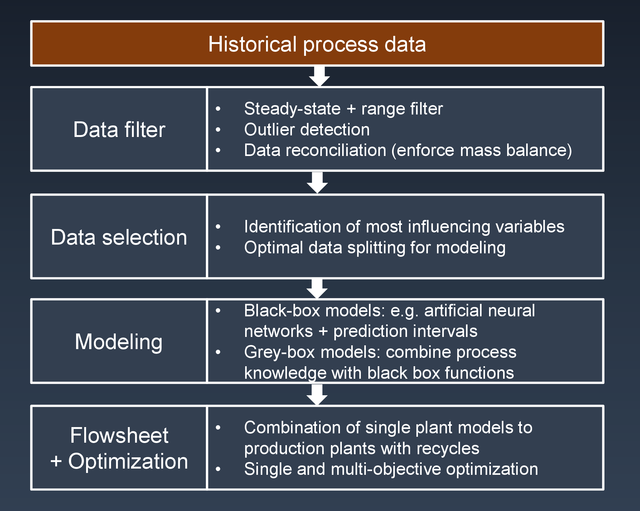

First, the optimal use of historical process data by using data filters and identifying the key variables that have the strongest influence on critical process parameters such as product qualities, temperatures and pressures.

Second, the modeling of plants using data-driven modeling techniques based on statistical models such as linear and nonlinear regression, artificial neural networks, Gaussian process regression or support vector machines.

Third, the coupling of black box models for the simultaneous optimization of several plants using evolutionary optimization algorithms, which enable multi-criteria optimization for the comprehensive consideration of several factors influencing the operation of process engineering plants.

Fabian Zapf

Dipl.-Ing., BSc

fabian.zapf@student.tugraz.at

- Digitalization

Back to Group overview.