Production of the Future

Upcoming Conferences

EuProGigant Open House Day 2024

Date: 08. October 2024, EIT Manufacturing, Palais Ferstel, Strauchergasse 4, 1010 Wien

18th European Congress and Exhibition on Advanced Materials and Processes

Date: 14.-18. September 2025, Granada

The 14th International Seminar "Numerical Analysis of Weldability"

Date: 21. - 24. September 2025, Schloss Seggau

Contact

Christof SOMMITSCH

Univ.-Prof. Dipl.-Ing. Dr.techn.

Spokesperson of Smart Productiom Graz

Phone: +43 316 873 7180

christof.sommitsch@tugraz.at

Participating Institutes of TU Graz

smartfactory@tugraz

smartfactory@tugraz is a research and learning factory equipped with state-of-the-art production and communication facilities at TU Graz. Here, disruptive technologies, the links between IT and OT levels, and safe working interactions of often highly heterogeneous aggregates are tested and demonstrated using showcase projects. To ensure a smooth operation under the best possible framework conditions, several production robots are available, and communication is handled quickly and securely via TU Graz’s own 5G network. Rudolf Pichler, head of smartfactory@tugraz, says: “We welcome any company that wishes to implement and test their ideas at smartfactory@tugraz. Smart production systems can be not only useful to large industrial companies, but they can also offer small and medium-sized companies in particular valuable opportunities to increase performance.”

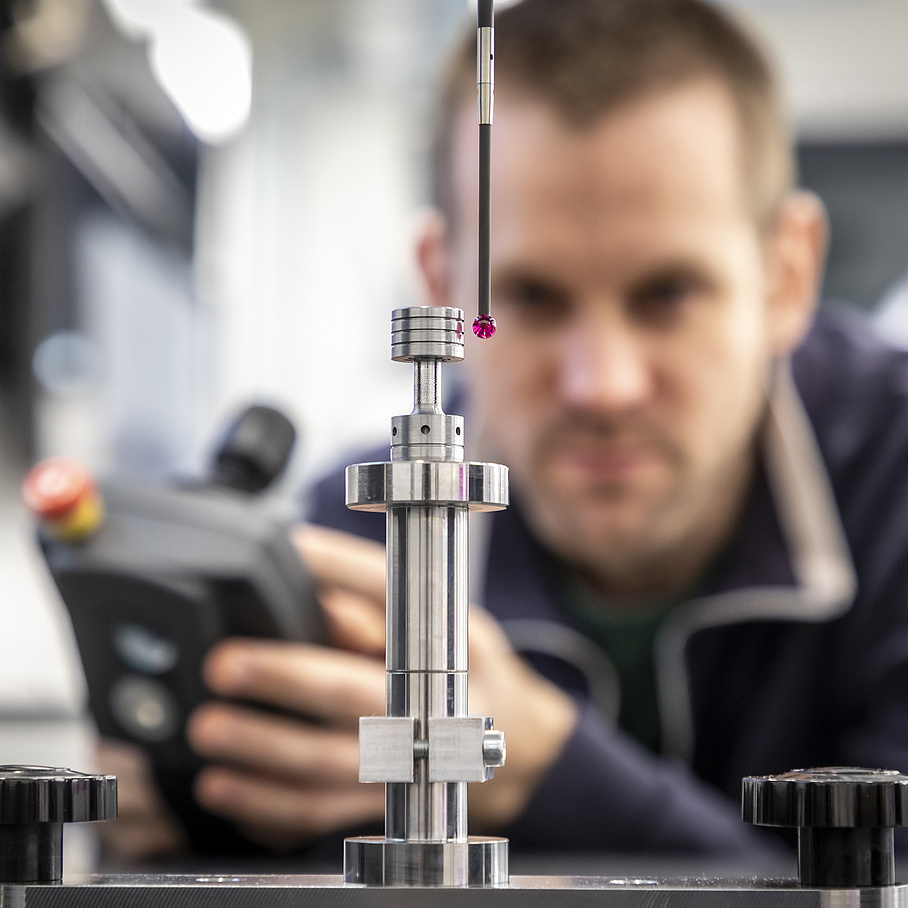

Infrastructure

Hardware:

CNC lathes (DMG MORI NLX, Spinner TC 400), CNC 5-axis milling machine (Spinner UR 630), a 3D coordinate measuring machine, a tool measurement system, collaborative assembly robots (2x UR5, 1x Fanuc), an AGV shuttle with gripper arm, a mobile robot, press-in devices (1x electric, 1x pneumatic), a laser marking unit, a screwing station, a function test bench, RFID reading stations, and much more.

Software:

PLM software (Teamcenter) by Siemens, ERP software proALPHA, MES software Solidat, special software for individual units, data and network architecture by T-Systems, along with server and network operations by TU Graz.

Contact

smartfactory@tugraz

The Learning & Research Factory of TU Graz

Inffeldgasse 25/f

8010 Graz

Phone: +43 316 873 7671

smartfactory@tugraz.at

Schumpeter Laboratory

The Schumpeter Lab teaches and researches tools for product development from idea generation to finished prototype. Rapid Prototyping and Design Thinking are just two examples. Students and researchers from all disciplines, as well as start-ups, SMEs and established industrial companies meet here for joint innovation work.

Infrastructure

A flexible, multi-functional and multimedia room (DesignLab) can be used for workshops, lectures with up to 120 people or panel discussions. The 3D-capable video wall with 4K resolution is also used for virtual prototyping. In addition to the meeting area, the FabLab is the heart of the lab. From state-of-the-art 3D printing equipment for FDM, STL, and CFF processes, to CNC 4-axis and CNC 3-axis milling machines, to equipment for laser cutting and engraving, waterjet cutting, sandblasting, PCB printing, or vinyl cutting.

Contact

Christian RAMSAUER

Univ.-Prof. Dipl.-Ing. Dr.techn.

Institute of Innovation and Industrial Management

Kopernikusgasse 24/II | 8010 Graz

Phone: +43 316 873 7290

christian.ramsauer@tugraz.at

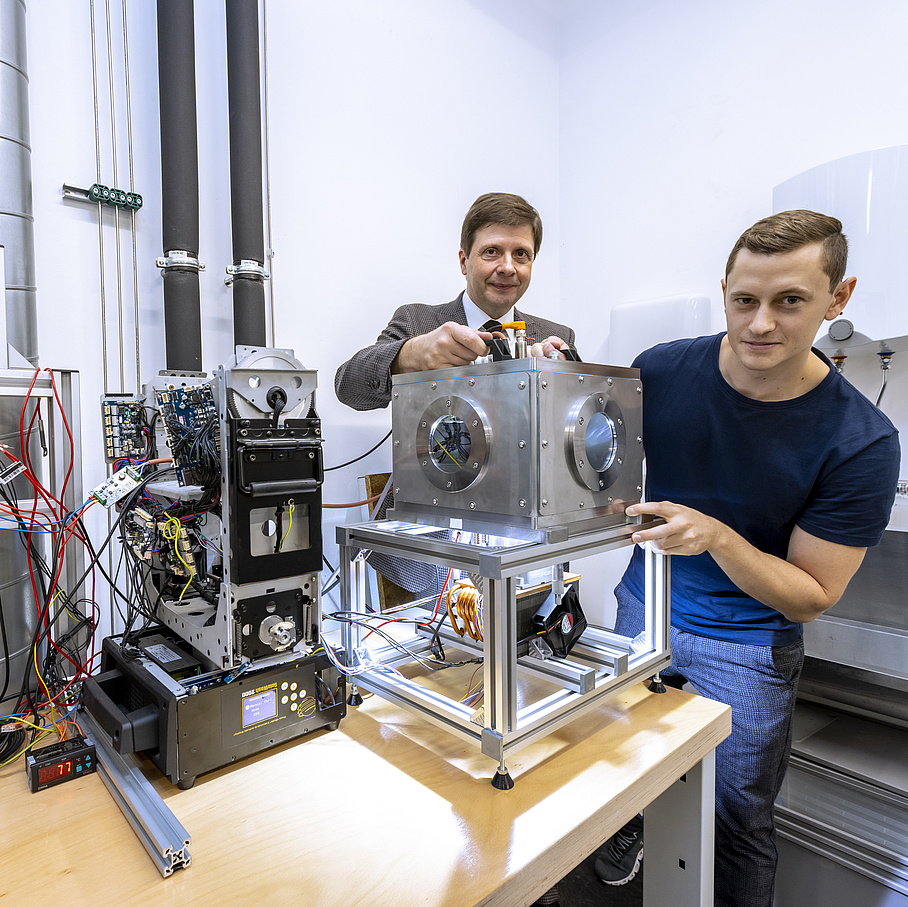

Additive Manufacturing Lab (AddLab)

At the TU Graz AddLab, researchers are experimenting with state-of-the-art 3D printing technologies; through a process of optimisation, the machines are being made available for the AddLab’s additive manufacturing pilot factory. The goal of this project is to pave the way for the production of lightweight products with complex designs that can maintain the necessary mechanical properties, all while using as few resources as possible. The AddLab is a cooperative effort between the Institute of Production Engineering and the Institute of Materials Science, Joining and Forming.

Infrastructure

- ORLAS Creator RA (Laser Power Bed Fusion)

- SLM 280 HL (Powder Bed Fusion Printer)

- Electron Beam Welding

- Wire-based 3D printing WAAM

- Intamsys FUNMAT HT Enhanced (Fused Filament Fabrication)

- Ultimaten S5 (Fused Filament Fabrication)

Contact

Franz HAAS

Univ.-Prof. Dipl.-Ing. Dr.techn.

Institute of Production Engineering

Kopernikusgasse 24 | 8010 Graz

Phone: +43 316 873 7170

franz.haas@tugraz.at

Joining Lab

At the TU Graz Joining Lab, researchers experiment with different welding processes, such as arc welding, electron beam welding, and friction stir welding. Their focus is on new welding processes that use homogenous and heterogenous materials, specifically, aluminium, steel, copper, magnesium, titanium, and other alloys.

Infrastructure

- Plasma Welding

- Arc Welding

- Friction Stir Welding

- Electron Beam Welding

- HAZ Simulation

Contact

Christof SOMMITSCH

Univ.-Prof. Dipl.-Ing. Dr.techn.

Institute of Materials Science, Joining and Forming

Kopernikusgasse 24 | 8010 Graz

Phone: +43 316 874 7180

christof.sommitsch@tugraz.at

LEAD Factory

The learning factory "LEAD Factory" is a realistic production environment consisting of workstations for the assembly of a commercially available scooter with approximately 60 individual parts. The topics covered are Lean production, Energy efficiency, Agile production and Digitalization. Students are learning in practical exercises to identify inefficient processes, derive measures and implement solutions for modern and efficient production. Production logistics, ergonomics and factory planning play a central role. A production line with electroplating for a component is demonstrated to demonstrate quality assurance and resource productivity. The LEAD Factory not only demonstrates state-of-the-art technologies, but also serves research purposes.

Infrastructure

The assembly line uses industry-standard Bosch-Rexroth assembly tables along with pneumatic and electric screwdrivers, a system for workplace logistics, a central warehouse with Milkrun, Andon lamps, workplace instructions (physical and digital), 3D printers and CNC milling machines, and many more digital tools.

A drill-milling machine with a handling robot, an electroplating system and an image recognition system for quality assurance are used to produce components.

An RFID system forms the backbone of digitalisation for a real-time shop floor management board. An ERP/MES system, assistance systems such as VR glasses and exoskeletons as well as various sensors and energy measuring devices are also used.

Contact

Christian RAMSAUER

Univ.-Prof. Dipl.-Ing. Dr.techn.

Institute of Innovation and Industrial Management

Kopernikusgasse 24/II | 8010 Graz

Phone: +43 316 873 7290

christian.ramsauer@tugraz.at

Competence Centers

In addition to TU Graz institutes from several faculties, two competence centres are integrated into the Research Center Smart Production Graz. Pro²Future and Know-Center primarily focus on research collaborations with industry. This helps to build additional bridges to private industry.