Railway tracks in alpine regions consist of many curves with small radii of often less than 300m. There, the elastic pads that are mounted in between the rail and the sleepers are affected by enormous stresses. In the narrow curves, the elastic pads must be replaced every few years which is time consuming and cost intensive. If the deterioration of the elastic pads is not detected in time, the sleepers will be damaged too, and as a consequence the train traffic needs to be shut down during its replacement. Mainly, horizontal forces are assumed to cause the accelerated deterioration of the elastic pads. Consequently, more durable materials are under development currently. However, the forces that are generated by a train passage and subsequently the strain inside the elastic pad are insufficiently known.

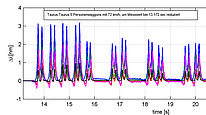

In this project, a fiber-optic rail-strain-pad (RASP) is developed. Several fiber Bragg grating (FBG) sensors are embedded into the elastic pad during the production process. Challenges in the development were the very small dimensions of the structure (size of the pad: 150mm x 160mm x 7mm) and the large strain values of several 1000με that are induced by loading the pad. Draw-tower gratings were used, as this sensor type was the only one to withstand the large strains of more than 30000με. Several RASP prototypes were developed and tested. Experimental results are shown in order to demonstrate the capabilities of the system to measure large strains. In future, the RASP will be used for weigh-in-motion issues.