Emulsions with Nanoparticles for New Materials

- Prof. Dr. Günter Brenn, Institute of Fluid Mechanics and Heat Transfer, Graz University of Technology, Graz, Austria

- Prof. Dr. Peter Kralchevsky, Laboratory of Chemical Physics and Engineering, Sofia University, Sofia, Bulgaria

- Prof. Dr. Tomasz Kowalewski, Department of Mechanics and Physics of Fluids, Polish Academy of Sciences, Warsaw, Poland

The design of new procedures for the fabrication of nano-structured materials is one of the “hot topics” in current materials sciences. The reason for the great interest is due to the great potential for applications of these materials in various modern technologies. Examples relevant to the present project are: nanostructured surfaces for photo-electrochemical and photo-catalytic processes; paint coatings of new optical properties; structured nanoporous materials using colloid crystal templates; preparation of core-shell colloid particles of various structures and compositions; micro-capsules for encapsulation of drugs, enzymes, minerals, dyes, phase-change materials, etc., and as micro-reaction cages.

The main purpose of the joint work in this project is to explore several new and promising directions for the fabrication of nano-composites (colloidosomes, microcapsules, core-shell and other composite particles), as well as nano-structured surfaces and porous layers by using emulsion droplets as precursors and/or templates. Sketches of these processes are given in Figure 1. The procedures involve the formation of emulsions stabilized by solid particles. Therefore, a large fraction of our efforts is directed to reveal the main factors governing the process of emulsification and the emulsion stability in the presence of solid particles.

Aims of the project

- Developing procedures for obtaining composite colloid particles by using emulsion droplets as templates or precursors.

- Deeper understanding of the emulsification and emulsion stability based on new knowledge about the hydrodynamic (turbulent), capillary and interparticle forces operative in the three emulsification methods shown in Figures 2-4.

- Formulation of criteria and conditions which lead to the formation of mono-disperse emulsion droplets, covered by nano-particles by means of the jet breakup method and by membrane emulsification.

- Predictions about the emulsion type and average drop-size as a result of agitation of two immiscible liquids in the presence of solid particles with certain properties (size, concentrations, hydrophobicity, etc.).

- Comparative study of the performance of particles and surfactants as emulsifiers.

- Preparation of nano-structured surfaces and porous materials with a controlled thickness and pore-size distribution in the layers. Acquiring information about how the other important properties of the layers (e.g., optical properties, mechanical strength, etc.) can be controlled by varying the properties of the used primary particles and emulsion drops.

Figure 1. (a) Schematic presentation of the process of particle assembly on the surface of emulsion drops, which can be used to produce (b) "colloidosome" or (c) "core-shell" type of particles. (d) and (e) Formation of particulate layers from colloid particles (including colloidosomes and core-shell particles) by the method of convective self-assembly.

Figure 2. Schematic presentation of the processing element in the narrow gap homogenizer. The turbulent eddies, formed in the narrow slits of the processing element, lead to emulsification of the phases passing through the homogenizer.

Figure 3. Schematic presentation of the emulsification process by using porous glass membrane. The oil phase is extruded through the pores of the porous glass membrane. Monodisperse oil drops are formed in the external aqueous phase under appropriate conditions.

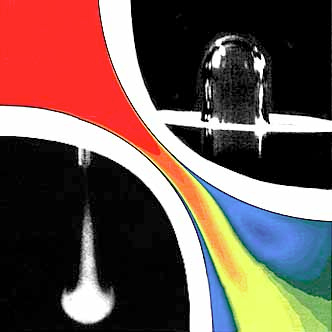

Figure 4. Schematic presentation of the emulsification process by capillary instability of a liquid jet in a co-axial flow.

Meetings- Kick-off Meeting in Sofia, 30.10.-2.11.2003

- Mid-Term Meeting in Warsaw, 28.-30.10.2004

- Final Meeting in Graz, 28.-29.10.2005

Slowicka, A., Walenta, Z.A. (2004) Conditions for creating thin liquid layers at the contact surface of two other liquids, ICTAM 2004 Abstracts Book and CD-ROM Proceedings, IPPT PAN Warsaw, 69

Blawzdziewicz, J., Wajnryb, E. (2004) High-frequency linear viscosity of emulsions composed of two viscoelastic fluids, ICTAM 2004 Abstracts Book and CD-ROM Proceedings, IPPT PAN Warsaw, 91

Tcholakova, S., Denkov, N.D., Ivanov, I.B., Danner, T. (2004) Main factors controlling the emulsification process under turbulent conditions. Experiment and data interpretation, ICTAM 2004, IPPT PAN Warsaw, Poster

Denkov, N.D., Tcholakova, S., Ivanov, I.B., Vankova, N., Danner, T. (2004) Main factors controlling emulsification in turbulent flow, Conference on Physics and Design of Foams, Unilever R&D, Edgewater, New Jersey, Poster

Kralchevsky, P.A., Danov, K.D., Kolev, V.L., Gurkov, T.D., Temelska, M.I., Brenn, G. (2005) Detachment of oil drops from solid surfaces in surfactant solutions: Molecular mechanisms at a moving contact line, Industrial & Engineering Chemistry Research 44, 1309-1321

Danov, K.D., Kralchevsky, P.A., Naydenov, B.N., Brenn, G. (2005) Interactions between particles with an undulated contact line at a fluid interface: Capillary multipoles of arbitrary order, Journal of Colloid and Interface Science 28, 121-134