CD-Laboratory for Continuous Solidification Processes

Period: October 1997 - August 2001

Head: Prof. Dr. Wilhelm Schneider, Institute of Fluid Mechanics and Heat Transfer, Technical University Vienna

Provisional head: Prof. Dr. Uwe Schaflinger, Institute of Fluid Mechanics and Heat Transfer, Graz University of Technology, until his death in April 2000. After April 2000 the project work at the institute was supervised by Dr. W. Meile.

The main objectives of this laboratory are problems in continuous casting of steel, and the suitable mathematical modelling of different processes. In 1997 one part of this laboratory was established at our institute. This part comprises two projects which are investigated in close cooperation with industrial partners.

________________________________________________________________________________A) Clogging and impurities in tundishes

During continuous casting processes impurities like deoxidation products in the melt deposit at the walls of the tundish nozzle and the stopper. This phenomenon, termed clogging, causes obstruction of the flow and decreases the quality of the product. A detailed knowledge of the flow pattern within the tundish nozzle-stopper region is very important for the design of appropriate nozzle and stopper geometries. By means of a numerical simulation the important influence of turbulence on the velocity field of the liquid metal in the nozzle region could be demonstrated - most particles close to the walls are deposited in case of high turbulence. A new design for the nozzle-stopper region reduces turbulence, prevents recirculation and permits a weaker lateral particle transport. A further mechanism may cause inherent problems trough formation of sediment layers at the nozzle-walls: the suction of ambient air through the porous material of the submerged entry-nozzle. A specific test facility was built-up to study the correlation between different parameters (flow-rate, stopper position) and the pressures prevailing in the nozzle-stopper region.

On the other hand, the tundish itself is very important with respect to the quality improvement through a separation of inclusions. During the present studies, the flow of liquid steel has been investigated by experiments in a water model with different flow-control devices and by numerical analysis for both isothermal and non-isothermal conditions. The experimental studies were intended to enlarge the mean residence time of impurities, and the results could be validated by the isothermal calculation.

The tundish is not only a distribution vessel, but also a device to collect the impurities in the slag. However, because of the limited residence time very small deoxidation products are not able to reach the surface due to buoyancy effects. These particles move through the nozzle into the mold where they may cause abovementioned problems. A constant mass flow can only be maintained by a permanent change of the stopper position. This results in reduced productivity and quality, which is particularly severe in aluminium-killed steel.

Appropriate steel quality requires the reduction of impurities in the tundish and, therefore, various efforts are necessary in order to enhance steel purity during the production process. The removal of inclusions is affected by a variety of parameters -- the geometry of the tundish and the resulting flow field highly influence the quality of solidified steel.

The flow behaviour and the residence time of a tundish were studied experimentally in a water model by means of different visualisation methods. Furthermore, the concentration of a tracer in the tundish nozzle was measured. In addition, the temperature field was studied numerically by accounting for non-isothermal conditions. Experiments were performed in a full scale model of the tundish to investigate the influence of flow control devices on particle separation and residence time. It was found, that it is absolutely necessary to increase the plug flow fraction and to minimize the stagnant regions in order to improve steel purity. Dam-weir combinations were compared to turbulence inhibitors, and quite different flow behaviour could be recognized. The turbulence inhibitor creates a uniform flow field and increases the plug flow fraction, thereby increasing the mean residence time.

Further information on this project may be found in:

Ranegger, G., Meile, W. (2001) The effects of melt flow on particle separation and deposition in continuous casting tundishes, Part of final report Christian Doppler Laboratory for Continuous Solidification Processes.

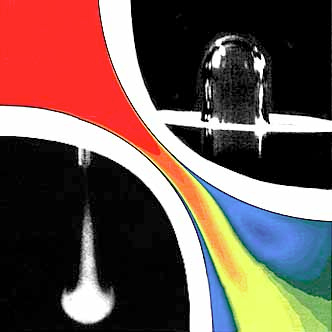

________________________________________________________________________________B) Bubble formation on porous refractories

Remark: This part of the CD-Laboratory is still continued as scientific research project described in Bubble Dynamics.In metal casting gas purging is used for purity improvement in order to fulfil todays high product quality demands. The impurities aggregate at the surface of the gas bubbles and are transported towards the slag by the ascending bubbles. Therefore, efficient flotation requires an optimal bubble volume, i.e. an optimal surface size. The present work deals with refractory surface factors which influence the volume of the generated bubbles essentially.

It is known that the bubble formation is strongly influenced by the non-wettability between the porous refractory and the melt. In our project we investigated the air bubble formation on aluminium, porous refractory and Teflon surfaces of different structure in water. The Teflon surfaces were used because of similarity reasons since the porous refractory is not wetted by the melt. The kinematic viscosity and the kinematic surface tension of water at room temperature and of liquid steel at 1600°C are nearly equal. Therefore, the influence of non-wettability, surface inclination and roughness on bubble shape and volume could be studied in our water model.

Our experimental arrangement consisted of a Perspex tank filled with distilled water. Various head-pieces were attached to the carrier through which the air was supplied. In order to study the influence of inclined surfaces the carrier was connected to a rotatable rod allowing a continuous change of the surface inclination. We tried to investigate single-orifices as well as multi-grid orifices, wettablility and non-wettablility of the surface - the major effect.

For the industrial application in gas purging a bubble column should contain bubbles of reasonable small size in order to achieve a capacious net surface with a reasonable bubble rising time. A situation as observed on the wetted aluminium grid would be the ideal case which cannot be achieved because of the non-wettability of the refractory surface by the melt. Thus, the aim of the present project was to find out about the influence of surface structure on bubble formation and volume resulting in scopes for design.

Further information on this project may be found in:

Teppner, R., Meile, W., Loimer, T. (2001) Bubble formation at inclined or porous surfaces, Part of final report Christian Doppler Laboratory for Continuous Solidification Processes.