Focused Ion Beam Processing (FIB)

During the last decade, focused ion beam (FIB) technology has attracted considerable attention as a rapid prototyping tool due to the direct-write character which allows the flexible fabrication of complex structures with 3D character even on non-flat surfaces. However, in combination with low melting materials, such as polymers or biological samples, chemical and morphological instabilities usually occur during FIB processing giving this combination the reputation of being incompatible.

Our scientific activities in this respective field led to recognition of a technically induced effect by means of classical patterning strategies. In the following we worked on a fundamental understanding of spatial temperature evolution which finally led to an alternative process strategy. The result are massively reduced local temperatures which minimize chemical degradation and maximize morphological stability at same process times. By that we could demonstrate that FIB’s are not incompatible to soft matter but requires adapted process strategies.

Our scientific activities in this respective field led to recognition of a technically induced effect by means of classical patterning strategies. In the following we worked on a fundamental understanding of spatial temperature evolution which finally led to an alternative process strategy. The result are massively reduced local temperatures which minimize chemical degradation and maximize morphological stability at same process times. By that we could demonstrate that FIB’s are not incompatible to soft matter but requires adapted process strategies.

Highlights

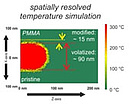

©FELMI-ZFE | Spatial temperature evolution during FIB processing of polymers: A combined simulation approach has been introduced to predict spatial temperature evolution during FIB processing of soft matter in agreement with correlated experiments. “A combined approach to predict spatial temperature evolution and its consequences during FIB processing of soft matter” by Schmied et-al, PCCP (2014), 16, 6153 |

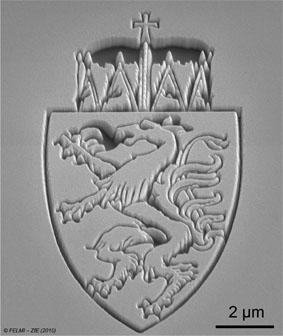

©FELMI-ZFE | Chemical degradation and morphological instabilities: In this study we could show the existence of a polymer creeping phase which follow the scanning ion beam finally responsible for morphological instability. Alternative process strategies have been optimized towards minimal chemical degradation and morphological stability as an essential step in this field. “Chemical degradation and morphological instabilities during focused ion beam prototyping of polymers” by Orthacker et-al, PCCP (2013), 16, 1658 |

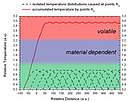

©FELMI-ZFE | Technically induced problems: In this work we shed light on technically induced temperature problems as a consequence of classically used patterning strategies. Also an alternative process is introduced strongly minimizing local temperatures. “New Possibilities for Soft Matter Applications: Eliminating Technically Induced Thermal Stress during FIB Processing” by Schmied et-al, RSC Advances (2012), 2, 6932 |

Contact

Institute of Electron Microscopy

and Nanoanalysis

Steyrergasse 17/III

8010 Graz

General Information

Verica Bursac

Phone: +43 (0) 316 873 8320

Fax: +43 (0) 316 373 8822

office@felmi-zfe.at

Service Related Inquiries

Hartmuth Schröttner

Phone: +43 (0) 316 873 8349

hartmuth.schroettner@felmi-zfe.at