MetaDesigner

Meta-Design Builder: A framework for the definition of end-user interfaces for product mass-customization

Project Partners

At the CGV:Dieter Fellner

Sven Havemann

Christoph Schinko At Fraunhofer IGD-A2:

André Stork

Thomas Gierlinger

At Fluidforms:

Hannes Walter, Stephen Williams

A FIT-IT project.

Description

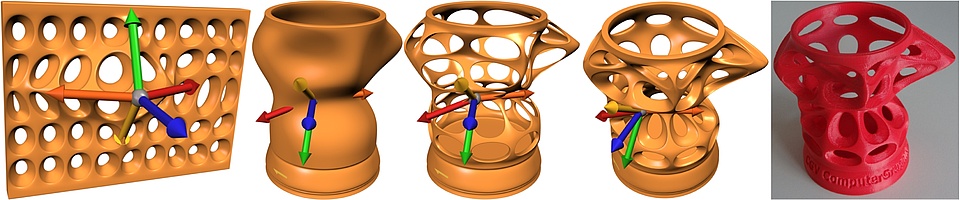

Rapid prototyping is the major new trend in manufacturing technology. Novel methods for 3D printing permit the greatest freedom in shape design. Various materials, such as paper, plaster, plastic, and even metal can be printed in 3D, and cost efficiency is improving drastically. While manufacturing technology is jumping ahead, end-user interface technology is lacking behind. Many products are not customized today because of the cost of providing an easy-to-use end-user interface, basically a customized, web-based 3D modelling toolkit. A number of projects exist in the area of mass-customization but almost all are based on the concept of only swapping pre-defined parts. Three dimensional shape customization integrated in online shops is offered at this stage only by Fluidforms and its very few competitors. The possible ways a product can be modified is defined by a meta-design. At this point a meta-design requires in depth knowledge of various technologies, mathematics and programming. To enable the navigation of a meta-design or the configuration of a product, not only the product domain, but also manufacturing technology, web technology, 3D programming and rendering must be mastered. The goal of the METADESIGNER project is to develop an enabling technology for creative minds with knowledge of consumer psychology, of design and market trends. It will let them create meta-designs and present them in optimal ways, online, without the need to deal with intricate technical aspects. The GML technology developed at TU Graz is ideally suited as a technical basis for this.Meta-Designs

Design

(1 object) --> Meta-Design

(parameterized object-family) --> MetaDesigner

(software to generate parameterized object-families)

METADESIGNER will focus on a representative selection of relevant case studies that cover a reasonable variety as well of product meta-design methods as of product manufacturing methods. The case studies are: (1 object) --> Meta-Design

(parameterized object-family) --> MetaDesigner

(software to generate parameterized object-families)

- Lamp

- 3D-community objects

- Jewelry

- Furniture

Generative Modeling Language (GML)

The METADESIGNER project will innovate on the technical level by introducing a novel communication protocol for the development and transmission of meta-designs for product customization, which gives access to interactive parametric 3D modelling of mesh-based shapes. This technology will build on the Generative Modeling Language (GML). GML is a language for the formal description of parametric 3D models. Conventional 3D formats store a model as a list of geometric primitives (points, triangles, spline patches etc). The idea behind generative modeling is to replace objects by operations. So GML encodes not only the result of a construction process, but the construction process itself.Server Side Rendering

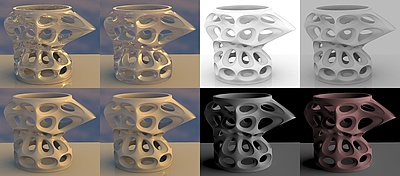

Fraunhofer IGD will contribute to METADESIGNER its stunning technology for generating realistic renderings of virtual models set into realistic surroundings. The car model finish is obtained from real measured car lacquer, the illumination is represented using an environment map. The image is composed using the HDR acquisition and rendering pipeline developed at IGD, in combination with dynamic Precomputed Radiance Transfer (PRT).

Fraunhofer IGD will contribute to METADESIGNER its stunning technology for generating realistic renderings of virtual models set into realistic surroundings. The car model finish is obtained from real measured car lacquer, the illumination is represented using an environment map. The image is composed using the HDR acquisition and rendering pipeline developed at IGD, in combination with dynamic Precomputed Radiance Transfer (PRT).