Simulation as an essential part of factory planning and optimization

Projects in the field of factory planning have been carried out at the IIM for years. While factory planning and optimization projects have already been accomplished several times with some long-term cooperation partners, in 2022 a cooperation in this context took place with some companies for the first time. One novelty, for example, was a planning project at a company in the semicon-ductor industry.

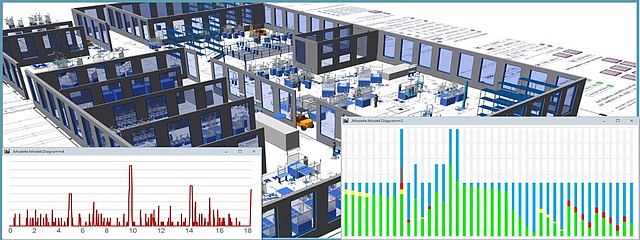

One trend that was particularly noticeable in this year's industrial projects is the increasing demand and acceptance regarding simulation-based planning and optimization of entire production net-works or individual factories. For the simulation of production systems with dynamic influencing variables (e.g. volatile demand, disruptions) and complex internal interactions (esp. job shop pro-duction), discrete-event simulations are usually used.

The IIM has been using discrete-event simulation in factory planning projects for years to validate planned concepts and for detailed planning

Simulation models are usually used to determine future resource utilization, to estimate the throughput times of relevant products, and to dimension storage and staging areas. Due to the increasing complexity of production systems and the spread range of project contents - from the redesign of a factory to detailed optimization tasks in existing production systems - the fields of application of simulation are changing in addition to the depth of detail of the planning tasks. This can also be seen in the following three projects, which, once again, represented real-world use cases for our Master's students.

Recently, an 8-month project with our new partner Unicor GmbH on the planning of a new location structure concept on a "greenfield" site was completed. The goal was not only factory planning, but also the targeted optimization of current assembly processes. With the help of a simulation model, current processes could be realistically represented, analyzed and optimized, which led to a signifi-cant reduction in throughput times.

In cooperation with the IFT (Prof. Franz Haas) a simulation-based planning of a production line for a novel product was carried out at Qualcomm Austria RFFE GmbH within seven months. On the basis of an extensive analysis of the existing pilot line an "upscaled" production line that also considers automation aspects was designed. Already at an early stage of the project, the planning object was modeled in a simulation. This enabled the planning of a logistics concept involving automated guid-ed vehicles, as well as testing design options in the area of production planning and control. Quanti-tative evaluation of design options considering target variables - such as work-in-process (WIP) and lead times - ensured that the future production system is optimized for various volume scenarios.

Also in 2022, a number of digitalization initiatives were realized at Palfinger AG. In this context, the first step towards a "digital factory" was taken at the Lengau site. The aim of the project was to map steel construction production by means of a discrete-event simulation. In addition to the feasibility test, first results on the system behavior were obtained via simulations. The focus was on the de-velopment of alternative production control rules to reduce WIP in order to reduce both tied-up capital and space used within production. Moreover, measures could be tested to keep the impact of disruptions (e.g. worker shortages) on the system performance low. It could be shown that the system output can be increased by approx. 10% even without expanding the machine park or addi-tional production shifts.

- IIM goes ISAM 2022 – Participating at the International Symposium of Academic Makerspaces

- Extension of the LEAD Factory

- Successful completion of research project “Voladigital”

- Simulation as an essential part of factory planning and optimization

- Innovation Gala 2022 - The highlight of the project Product Innovation (PI)

- Whitsun Dialogue Styria 2022

- Save the Date: IIM Alumni Event 7th of June 2023