Pollen measurement system developed at TU Graz analyses pollen fast, cheaply and automatically

Additional pictures for download at the end of the text

Pollen: essential for the pollination of many plants, but the bane of allergy sufferers. Pollen warning services provide information about daily exposure and allergy risk and are an important source of information for affected persons. For common data collection, pollen traps are used which continuously measure the pollen content in the air. To do this, they use a built-in electric motor to suck the ambient air into a drum where the pollen in the air sticks to an adhesive strip. Professionally trained persons then evaluate the pollen microscopically and grade it. However, the procedure is costly and time-consuming. Automated solutions are currently too expensive and only suitable for a limited number of pollen species. Olga Saukh and Nam Cao, two researchers from the Institute of Technical Informatics, have now joined forces with a team from ETH Zurich to develop a prototype of a pollen measurement sensor that could dramatically simplify the entire process – from catching the pollen to recording and evaluating it.

Simple, inexpensive, lightweight

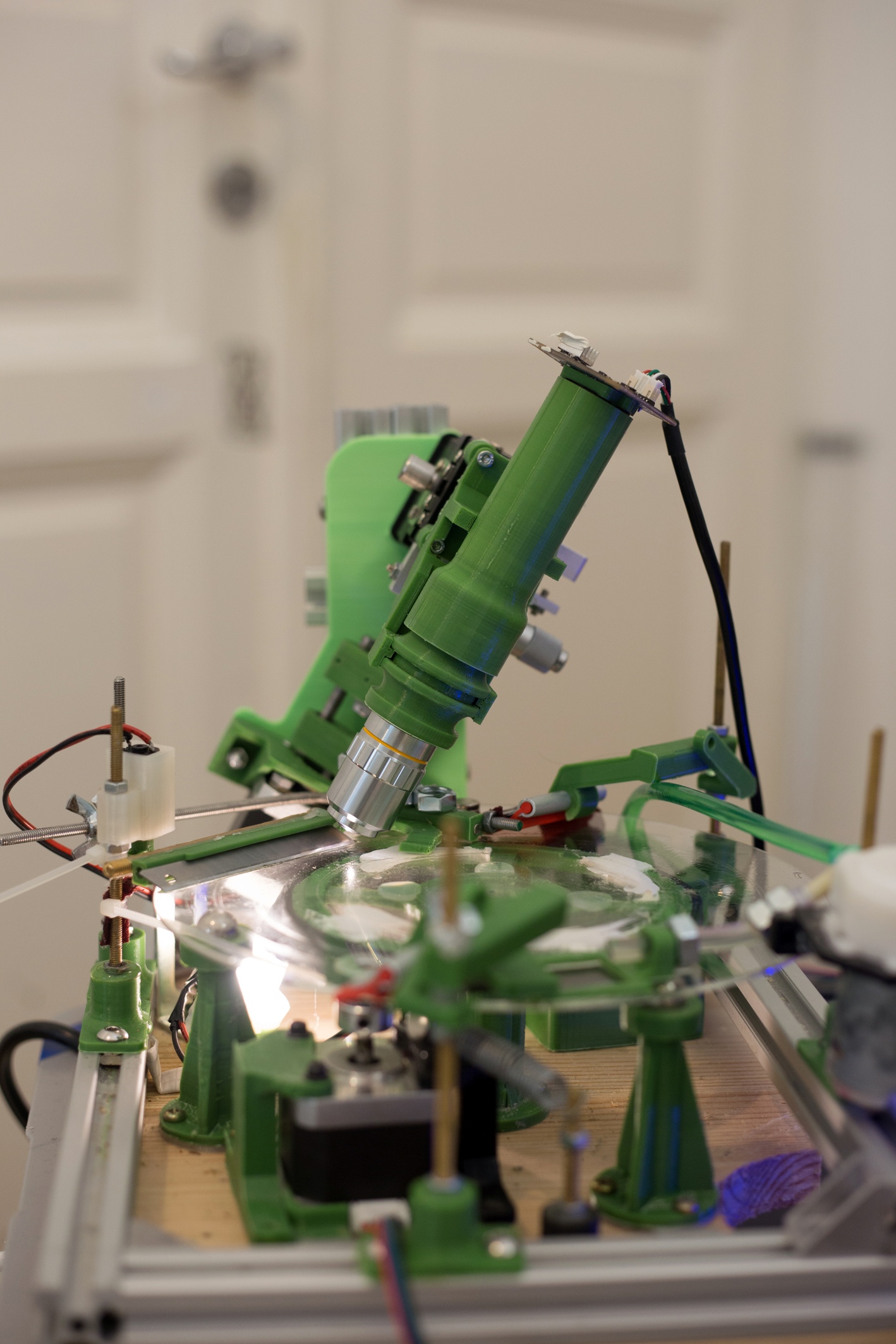

The pollen measurement system consists of two parts: a measuring device, which includes a pollen trap, a particle concentrator and a digital transmitted light microscope, and a cloud service, in which the microscopically recorded pollen images are analysed. The prototype is particularly light (8 kg), compact (30 cm x 40 cm x 44 cm), energy-saving (the power consumption is 6W) and can be implemented at low cost. "The material costs amount to around 1000 euros," says Olga Saukh. In comparison: currently available fully automated pollen measuring devices cost up to 100,000 euros.

The pollen trap has six inlets that can collect pollen from all directions of flight. “We’ve been inspired by modern vacuum cleaner technologies and use a cyclone to collect the pollen samples, as is used for bagless vacuum cleaners that collect the sucked up dirt in a collection container," explains Nam Cao.

Further information on Olga Saukh's research can be found in the Planet Research article "Human and Machine Interaction in Complex Systems".

How the pollen measurement sensor works

The pollen lands inside the device on a clockwise rotating glass plate which is covered with a thin layer of glycerine. The glycerine fulfils two essential tasks. On the one hand, it ensures that the pollen grains stick to the glass surface. On the other, it improves the quality of the images that the microscope sends to the cloud. "Glycerine is transparent, does not evaporate and is also suitable for outdoor use due to its thermal stability," says Olga Saukh, explaining the choice. Using a standard paper cutting blade, the glycerine-soaked pollen are concentrated to a thin line. The narrower this line is, the more pollen can be recorded under a microscope and then analysed. The pollen is then automatically wiped off the plate such that the system can work autonomously for a long period of time.

Machine learning algorithms analyse the pollen

Up to 100 microscopic images are uploaded to the cloud in 30 seconds. An object recognition software identifies and classifies the pollen grains on the basis of various characteristics. In field trials, the pollen recognition model correctly recognized pollen in 90 percent of cases.

In order to be able to train and further improve the model using machine learning algorithms, the researchers manually annotated a subset of the recorded data. Now the researchers are working on further advancing the evaluation of the pollen. "This is an ongoing process, where we depend on the support of pollen experts," says Olga Saukh, referring to two open source platforms. The dataset is publicly available on the Zenodo platform. The hardware design and the image processing code are provided on the online service GitHub.

This research topic is anchored in the Field of Expertise Information, Communication & Computing, one of the five scientific research foci at TU Graz.

Kontakt

Olga SAUKH

bak. Ass.Prof. Dr.rer.nat. MSc

TU Graz | Institute of Technical Informatics

Phone: +43 316 873 6413

saukh@tugraz.at